The new 1254cc BMW Boxer engine with ShiftCam Tech

Larger new engine for R 1250 GS and R 1250 RT

BMW’s venerable Boxer engine enters yet another generation for model year 2019 with the advent of the R 1250 GS and R 1250 RT.

While the Boxer went to four-valves over 25-years ago (1992), it was not until it moved to double overhead cams a decade ago (2009) that it started to really win me over. Three years later, 2012, and the boost to the current 125hp, thanks to the move to water-cooling, the engine really came alive.

Now for 2019 the engine gains more capacity, growing from 1170cc to 1254cc, via both a longer stroke and an enlarged bore, and gains 9 per cent more power along with 14 per cent more torque.

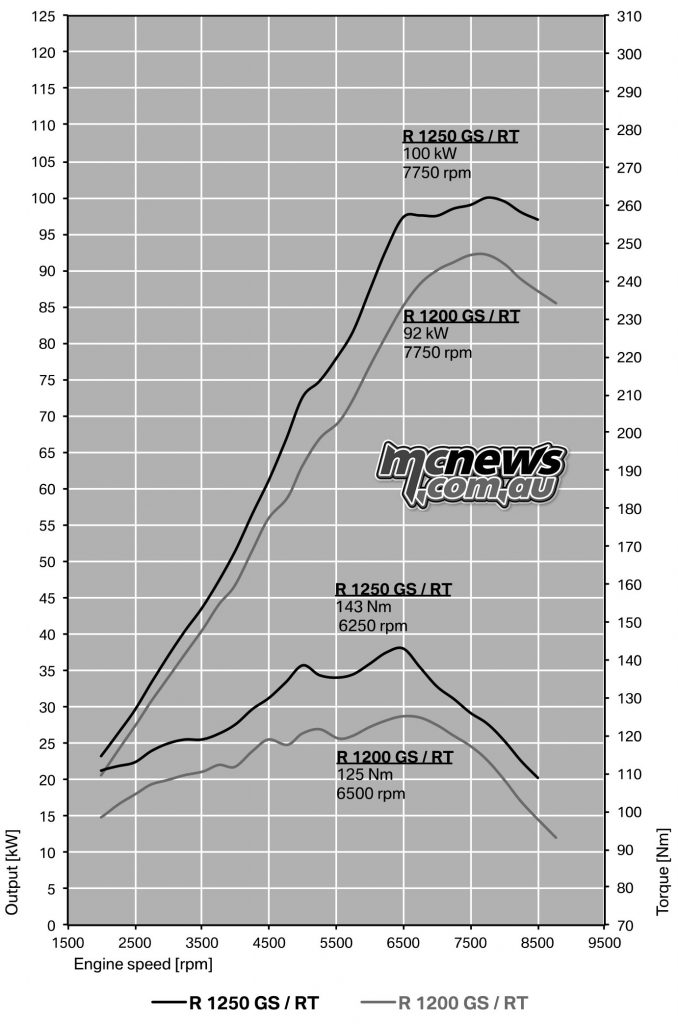

The new 1250 Boxer produces, according to BMW, 136 hp (100 kW) at 7750 rpm, and 143 Nm of torque at 6250 rpm. The outgoing model’s numbers were 125 hp and 125 Nm.

While there are improvements from idle all the way through to redline, from the accompanying dyno chart it appears that the greatest gains are made from 5000 rpm up. There is at least 110 Nm of torque available right from as low as 2000 rpm, and over 120 Nm from 3500 rpm.

New 1254cc BMW Boxer on Dyno

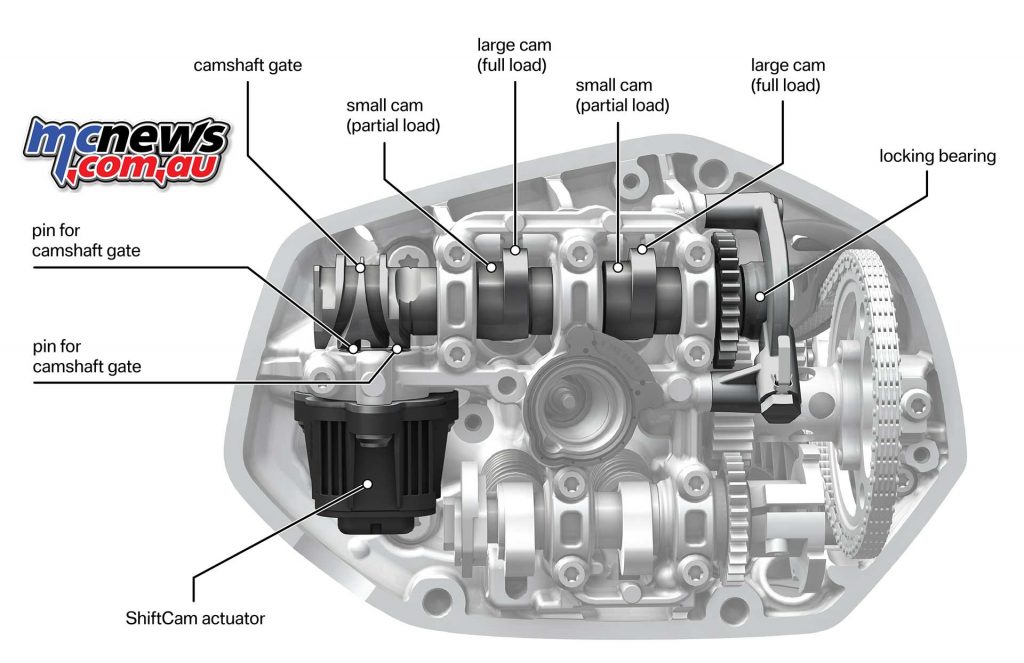

The other big news is the move to what BMW are calling ‘Shiftcam Technology. This is, essentially, variable valve timing of the inlet cam. The inlet cam has two sets of lobes, one set with shallow lift and modest duration, for great torque, reduced emissions and improved economy. While the second set of lobes are of a much more wild duration and lift, which promises a bit of a Jekyll and Hyde character to the new Boxer.

Engine idle speed is also lowered by 100rpm thanks to the Dr Jekyll set of cam lobes while fuel economy in some parts of the rev range is up to four per cent better than before.

The official guff on the new Boxer engine

While the previous boxer power unit itself provided supreme forward thrust in all situations, the boxer engine in the new BMW R 1250 GS and R 1250 RT takes this a significant step further. In the latest generation it has a capacity of 1 254 cc (previously: 1 170 cc). The ratio between bore and stroke is now 102.5 to 76 mm (previously: 101 to 73 mm). It has an output of 100 kW (136 hp) at 7,750 rpm and generates a maximum of 143 Nm at 6,250 rpm (previously: 92 kW (125 hp) at 7,750 rpm and 125 Nm at 6,500 rpm.

With a 7% capacity increase, the new boxer engine offers 14% more torque and 9% more output than its predecessor, making it the most powerful BMW boxer engine ever to be manufactured in serial production.

At its latest stage of development too, the boxer engine uses the well-established system of air/liquid cooling. So-called precision cooling means that the cooling fluid flows through the engine elements that are more heavily exposed to heat – namely the two cylinder heads and parts of the cylinders. Heat is dissipated via two radiators positioned at the left and right of the front vehicle section.

BMW ShiftCam Technology

The objectives in developing the new boxer engine in the R 1250 GS and R 1250 RT were to further enhance the already impressive output and torque figures of the predecessor model. This also involves a significant increase in refinement and running smoothness as well as optimised emission and fuel consumption levels.

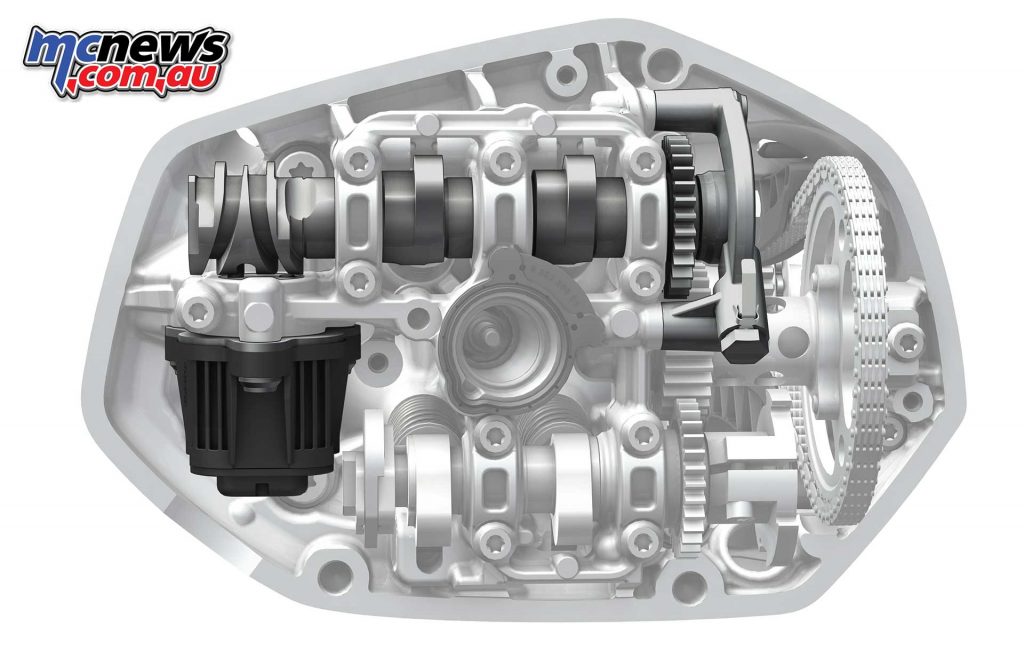

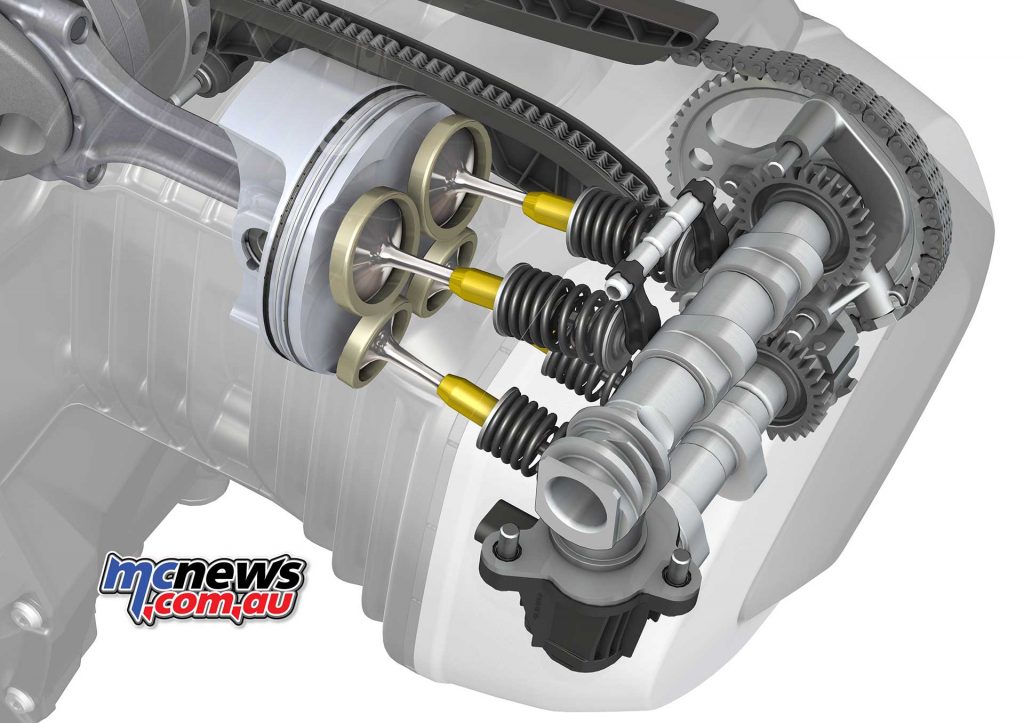

It was possible to achieve these enhancements by means of BMW ShiftCam Technology. This is a technology that is completely new to BMW motorcycles: its function is to vary the valve timings and valve stroke on the intake side. The core of the technology is a single-unit shift camshaft with two cams per valve to be activated: one partial-load cam and one full-load cam, each featuring cam geometry in optimised design. While the partial-load cam has been configured to ensure optimised fuel consumption and refinement, the full-load cam is designed for optimised output.

Axial shift of the intake camshaft means the intake valves are activated by either the partial-load or the full-load cam, depending on load and engine speed. The axial shift of the intake camshaft and the use of the partial-load or full-load cam are effected by means of a shifting gate on the camshaft and an electronic actuator which intervenes at this point.

Variation of the intake valve lift

Asynchronous valve opening

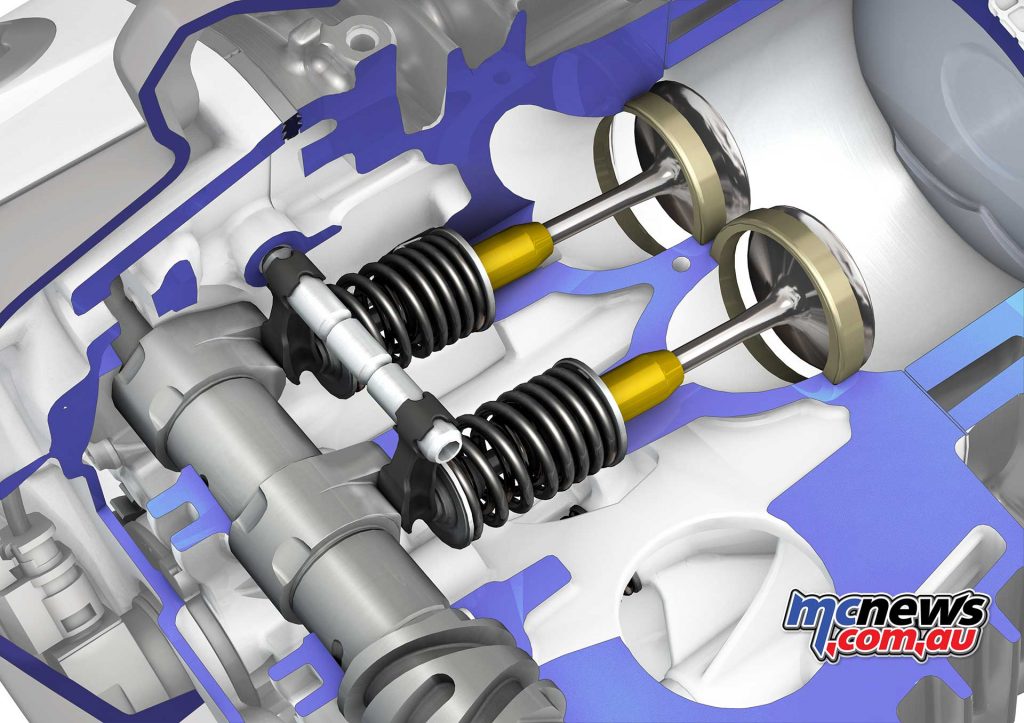

The varied configuration of the cam geometry also enables variation of the intake valve stroke. While the full-load cam provides maximum valve lift, the partial-load cam delivers reduced valve lift. There is also a difference between the intake cams for the left and right-hand intake valve in lift and angular position. This phase shift means that the two intake valves are opened to different degrees and on a time-staggered basis.

The effect of this phase shift is to create a swirl and therefore greater agitation of the fuel-air mixture flowing into the combustion chamber. This results in particularly effective combustion and better utilisation of the fuel as a result. Given the appropriate riding style, BMW ShiftCam Technology enables a reduction of fuel consumption by up to four per cent as compared to the already economical predecessor model.

Benefits of BMW ShiftCam technology

- Increased torque and pulling power across the entire engine speed range.

- Enhanced refinement and more even engine running when travelling at a constant speed due to optimum configuration of the partial-load cam geometry for the lower load range and engine speed range.

- Significant increase in peak output to 100 kW (136 hp) (previously: 92 kW (125 hp)).

- Reduction of load change loss in the partial load range.

- Reduction of idling engine speed by 100 rpm.

- Reduction of exhaust emissions and optimised sound.

- Reduction of fuel consumption by four per cent as compared to the predecessor model.

More torque, more smooth, more refined

In practical terms, BMW ShiftCam Technology results in an even further significant improvement in ridability for the new R 1250 GS and R 1250 RT in comparison to the predecessor model. In addition to the considerable boost in peak output from the previous figure of 92 kW (125 hp) to the current level of 100 kW (136 hp), it is the drastic increase in torque and therefore pulling power that is particularly noticeable.

In the range from 2 000 to 8 250 rpm, for example, the level of torque now available is 110 Nm. Within the range that is especially relevant in terms of riding dynamics, namely 3 500 to 7 750 rpm, the impressive level of over 120 Nm is now available. This gives the new R 1250 GS and R 1250 RT even greater supremacy and pulling power than before, combining absolutely superior power delivery with remarkable top performance – whether riding alone or with a passenger, on winding country roads or covering long stages of a journey at a high average speed. In short: never before has a boxer engine provided this level of riding fun and refinement.

Cylinder heads go vertical flow and cam drive gains teeth

The engine of the new BMW R 1250 GS and R 1250 RT also features vertical flow. The advantage here is that the configuration of the intake channel no longer depends on the camshaft control, so it was possible to realise identical intake lengths for both cylinder sides. What is more, the fuel injector is now arranged so that the fuel is injected as directly as possible in front of the intake valves for optimum atomisation.

As before, the two camshafts per cylinder side are powered by a chain running in the shaft behind the cylinders (on the right-hand side of the engine via the counterbalance shaft and to the left via the crankshaft). The timing chain drives an intermediate shaft between the intake and exhaust camshaft and it is from here that power is transmitted to the camshafts via spur gear pairs. The control chain is now a toothed chain (previously: roller chain) with the aim of further reducing running noise. As before, the four valves are arranged at close angles to one another in order to achieve an optimum combustion chamber shape. The valve angle is 8 degrees on the intake side and 10 degrees on the exhaust side, while the disc diameters of the valves are 40 mm on the intake side and 34 mm on the exhaust side. The valve shaft diameter is 5.5 mm. As before, the valves are operated via light, speed-resistant rocker arms, the design of which was derived from the high-performance 4-cylinder engine of the BMW S 1000 RR. The valve clearance settings are made by means of replaceable shims.

The increase in output and torque and therefore riding dynamics as a whole also involves two back-up measures to ensure maximum operating reliability: the two pistons have base cooling using splash oil and the lubrication system has been fitted with variable oil intake. By means of a shifting piston in the intake area of the oil sump, the latter ensures optimum oil supply in all riding states.

Improved knock sensors for low octane fuel

Unlike their predecessor models, the new R 1250 GS and R 1250 RT have a knock sensor system in the form of two knock sensors. This allows the use of fuels with a rating of less than RON 95 – a particular advantage when travelling in the more remote corners of the planet. The new R 1250 GS and R 1250 RT are also fitted with a new digital engine control, the so-called BMS-O. Its main features are fully sequential injection, a compact layout and low weight. Carburetion is carried out by an electronic fuel injection system via throttle bodies with an opening width of 52 mm. Injection is via new twin-jet injection valves that support even greater refinement and further improved emission levels.

Integrated gearbox with better shifts and improved slipper control

The gearbox and clutch are integrated in the engine housing in the new boxer engine, too. This provides benefits in particular in terms of overall weight due to the omission of numerous bolt connections and sealing surfaces, but also in terms of the torsional response of the unit as a whole. In addition to a design that saves both space and weight, this concept means that no additional gearbox volume is required.

Power transmission to the 6-speed gearbox, which has been further optimised in terms of gear shifting, is via a multi-plate wet clutch with eight friction discs. The clutch system is fitted with an anti-hopping mechanism. With this new drive generation, BMW Motorrad has thus especially addressed the wishes of riders with sporty ambitions who prefer country roads. The brake torque of the engine is now passed to the rear wheel at a reduced level during coasting. This prevents brief blocking or hopping of the rear wheel due to the dynamic wheel load distribution when applying the brakes heavily and changing down at the same time. In this way, the motorcycle remains stable and safely controllable during the braking phase.

New exhaust

Made completely out of stainless steel, the exhaust system of the new R 1250 GS and R 1250 RT is designed entirely for optimum output and torque in conjunction with BMW ShiftCam Technology and works according to the 2-in-1 principle. In this development area, a homogeneous output and torque curve and thus excellent ridability were once again regarded as requirements for supreme performance on country roads, off-road riding and extended touring activity.

The two manifold tubes and the interference pipe were redesigned in terms of shaping, length and diameter. Exhaust gas purification is taken care of by a closed-loop catalytic converter controlled by an oxygen sensor. In this way, the new R 1250 GS and R 1250 RT meet current exhaust standards and are excellently equipped for future requirements.

Riding Modes

Even in standard trim, the new R 1250 GS and R 1250 RT offer two riding modes for adaptation to individual rider preferences. Here, the standard Automatic Stability Control ASC ensures a high level of riding safety due to excellent traction. What is more, the riding modes “Rain” and “Road” allow adaptation of the bike’s properties to most road surface conditions. The set-off assistant Hill Start Control is likewise a standard feature in both models, enabling convenient set-off on slopes.

Acronym extravaganza!

Riding Modes Pro – Dynamic Traction – ABS Pro – DBC – HSC Pro

As an optional equipment item ex works, the new R 1250 GS and R 1250 RT can be fitted with the option “Riding Modes Pro”, featuring the additional riding mode “Dynamic”, Dynamic Traction Control DTC, and in the RT 1250 GS also the riding modes “Dynamic Pro”, “Enduro” and “Enduro Pro”. DTC enables even more efficient and safe acceleration, especially in banking position. The riding mode “Dynamic Pro”, and in the R 1250 GS “Enduro Pro”, both activated by means of a coded plug, also each have customisation options that allow the character of the motorcycle to be adapted to individual needs, thereby further enhancing the fun of riding.

ABS Pro (part of the optional equipment item Riding Modes Pro in the R 1250 GS and a standard feature in the R 1250 RT) also offers even greater safety when braking, especially in banking position, while Dynamic Brake Control DBC provides the rider with extra support on brake manoeuvres. DBC increases safety when braking, even in difficult situations, by avoiding unintentional acceleration from the throttle. By means of intervention in the engine control, the drive torque is reduced during braking, making full use of the braking power at the rear wheel. This keeps the motorcycle stable and shortens the braking distance. With the dynamic brake light (part of the optional equipment item “Riding Modes Pro” in the R 1250 GS, standard in the R 1250 RT), vehicles to the rear are made more aware of the fact that the motorcycle is decelerating.

The new optional equipment item Hill Start Control Pro goes beyond the functions of a comfort system such as Hill Start Control to facilitate stopping and setting off on a slope. Hill Start Control Pro offers the new additional function Auto HSC. The settings menu allows this additional function to be individualised in such a way that the parking brake is automatically activated on a gradient (greater than +/- 5 %) when the hand or foot brake lever has been activated, shortly after the motorcycle comes to a standstill.

BMW R 1250 GS / R 1250 RT Engine Specifications |

|