2017 Honda CRF450R Revealed

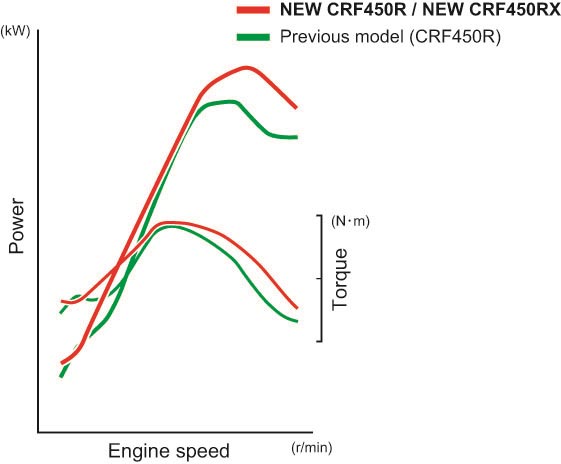

The 2017 Honda CRF450R is the first ‘from the ground-up’ redesign of the CRF450R for eight years, and packs a powered-up HRC designed engine with an 11 per cent overall power boost and stronger torque right through the rev range.

American CRF450RX version will not be coming to Australia

While America will also get a slightly modified version of the machine, with a nod to enduro use, dubbed the CRF450RX, there are no plans to introduce the RX variant of the model to the Australian market. It would take as much work to ADR the CRF450RX as it would for Honda Australia to prepare the full spec’ CRF450R for ADR eligibility. The American RX machine lacks the wiring and other bits and pieces that were present on the previous generation CRF450X machines sold in Australia. The 2017 RX machine has been specifically designed for GNCC competition use in America. Thus, those of us lucky enough to reside in states that have adopted the liberal recreational registration scheme, will, as per normal, just rec’ rego’ the full monty CRF450R.

Back to the machine we will be getting – the 2017 Honda CRF450R

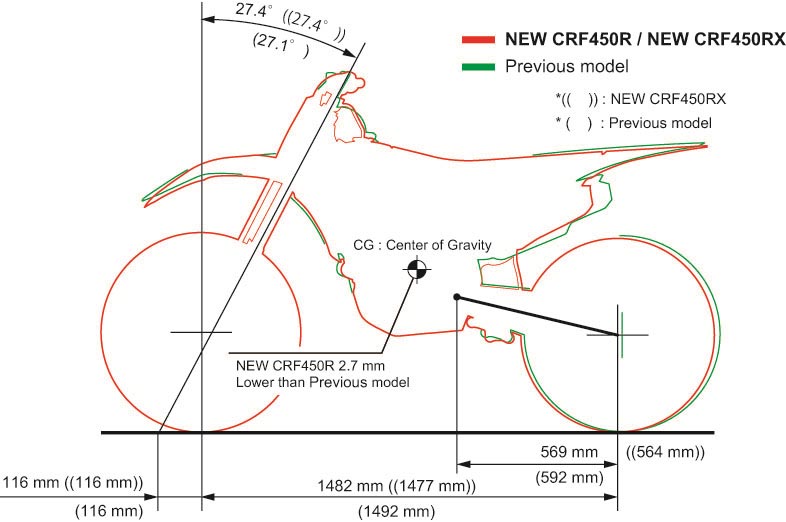

The 2017 Honda CRF450R gets an all-new seventh generation aluminium frame with new chassis geometry, lower centre of gravity and a titanium fuel tank making it lighter and more compact.

The new CRF450R is fitted with factory dervied 49mm Showa USD coil spring front forks, developed from a version supplied to MX race teams. They are everything one would expect from effectively race-spec suspension, the out of the crate fork action is supple, smooth and fully in control.

For the very first time, an electric-start kit is available on the CRF450R. Kit specification and local availability will be announced later.

The body is more compact with aerodynamically-efficient plastics with feature film insert graphics for optimum scratch resistance and a bolder effect.

Large Project Leader (LPL) for the 2017 CRF450R, Mr M. Uchiyama

“Nothing has been overlooked and we have been relentless in our effort to provide customers with a machine that’s ahead of the pack. We are proud to give a machine with this kind of performance to motocross lovers worldwide.” He added.

2017 Honda CRF450R Detail

Evolution of the engine and frame for “achieving the holeshot without fail” ”Let the rider earn the holeshot by all means!”

The key development goal for the CRF450R was enhancing its acceleration and starting performance to win motocross races. For securing the performance required, Honda reviewed and reconsidered from scratch, the layout of the whole motorcycle and all components.

To improve the acceleration performance, it is important to increase engine output while ensuring traction for the rear tyre. Preventing the front end of the motorcycle from lifting is also very important. To achieve these targets;

- the engine torque has been increased

- the load allocated to the rear area has been increased

- the center of gravity has been lowered.

Increase in engine torque

- Finger follower rocker arms have been added to the new-generation Unicam engine, increasing the valve lift.

- A revision of the intake and exhaust system layout has improved charging efficiency.

- Changing the valve included angle has achieved a flatter combustion chamber shape with outstanding combustion characteristics.

- Use of a scavenge pump has reduced pumping loss.

Lowering of the center of gravity

- Weight reduction was achieved for the fuel tank, given its position with a relatively high centre of gravity

- A smaller muffler is used.

- The rear shock is positioned with a lower C of G

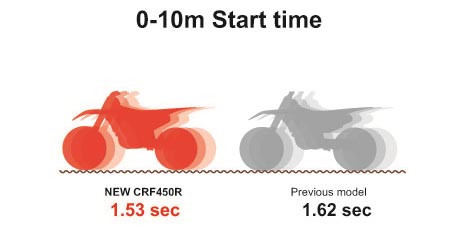

Honda claims that testing results have sown that in the first 10 metres out of the gate a tenth of a second improvement has been found in the new model. 1.6-seconds for the first 10 metres in the current machine, versus 1.53-seconds for the 2017 CRF450R.

Engine / Overview

The power unit of the CRF450R is a new-generation Unicam engine with increased valve lift. Revisions of the intake and exhaust ports and changes in the valve included angles and piston shape have optimised the combustion chamber design and increased the compression ratio from 12.5 to 13.5, enhancing the power in the entire speed range of the engine in comparison to the previous model.

Also, a revision of the route for engine oil has led to a reduction in oil pumping loss.

As an optional feature, installing a starter motor is now possible.

Engine of the CRF450R

The engine output of the new CRF450R is higher in almost the entire range, compared to the previous model

Engine / Unicam system

For the new-generation Unicam engine, the valve lift has been increased and improvements have been made in the maximum speed range, to increase the torque and power output through the entire range.

Installed anew on the intake side are finger follower rocker arms, further increasing the lift and the charging efficiency for the fuel-air mixture. Lift on the intake has gone from 9.5 to 10mm while on the exhaust valve lift is increased from 7.95mm to 8.8mm.

Each valve spring has an oval cross-section shape, which increases the lift while limiting engine height compared to the previous circular cross-section shape, thus contributing to lowering the center of gravity for the whole vehicle.

Engine / Port shape

For the intake port of the newly developed engine, a revision of the valve angle and adoption of finger follower rocker arms has achieved a straight intake port shape.

Thanks to these changes, there is now no load on the flow of the fuel-air mixture in the port, increasing charging efficiency for the fuel-air mixture.

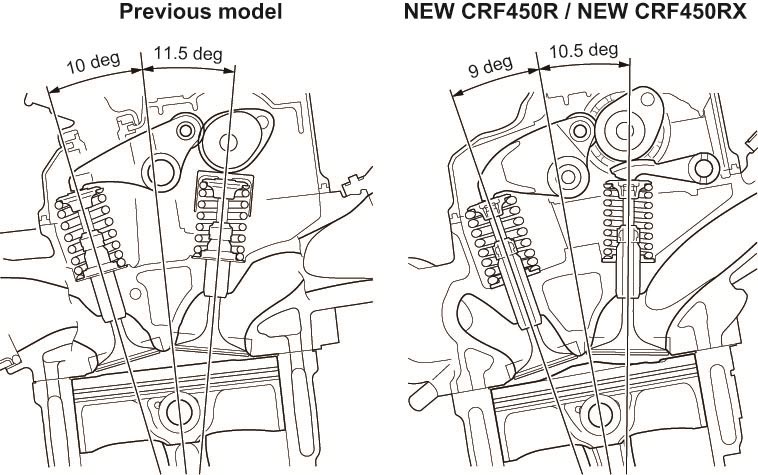

Valve angle and piston shape

Narrowing the valve angle compared to the previous model has reduced the surface area of the combustion chamber, restraining knocks and increasing the compression ratio.

Enlarging the valve size on the intake side and revising the piston head shape as a result has led to increases in the combustion efficiency, power output and torque, in comparison with the previous model.

Engine / Scavenge pump system

For the engine of the CRF450R, use of a more advanced scavenge pump system has discharged oil and air from the crankcase, and maintaining a negative pressure has reduced pumping loss, leading to less friction inside the engine.

Adoption of this system increases rotational efficiency of the engine in the high-speed range compared to the previous model.

Also, using the discharged oil for lubrication of the clutch and transmission systems has reduced the weight of the oil system and the total transmission oil volume, thus achieving a reduction in the oil friction.

Oil quantity

- Previous model: Engine 670ml + Transmission 720ml = 1390ml

- New CFR450: Engine 1250ml

Engine / Improvements in the parts

- To reduce the friction loss due to the friction among parts, diamond-like carbon (DLC) coating has been applied to the key engine parts: the finger rocker arms and piston pins. * DLC: Diamond-like carbon

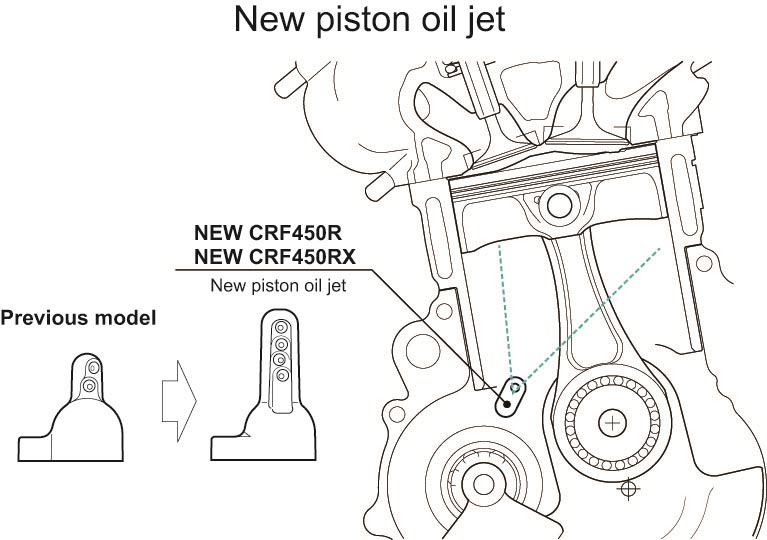

- For the new piston cooling oil jets, the number of jet nozzles was increased from two to four and the injection range was expanded, for further reducing the piston temperature. This has enhanced cooling and lubrication, achieving a higher compression ratio as a result.

- For the intake system of the new CRF450R, a revision of the installing position for the rear suspension and changes in the ports on the intake side for the air cleaner case and engine have achieved a straight air intake layout design, with a straight intake air passage connecting from the air cleaner case to the combustion chamber. This has reduced air resistance in the intake air passage, leading to improvements in the throttle response and increased engine output.

- For the exhaust system of the CRF450R, creating gentler curves for the exhaust pipe shape and a smoother exhaust system layout has achieved a more efficient exhaust that is in step with the high compression ratio, contributing to a rise in the engine output. Revising the layout of the exhaust system has enabled moving up the muffler end by 78 mm toward the front, contributing to mass concentration and a more agile ride feel.

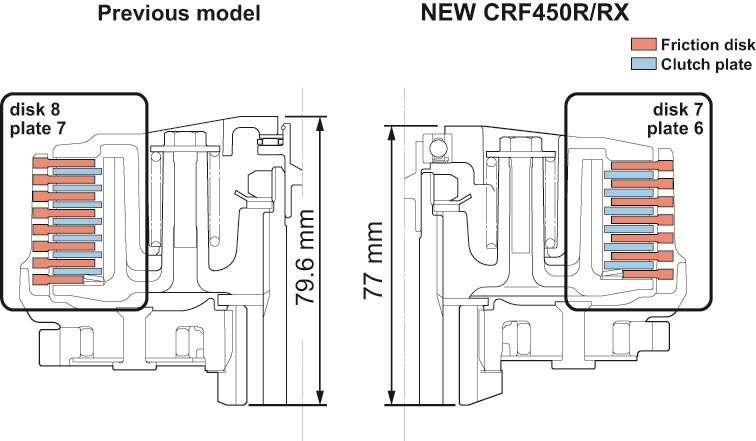

- Increasing the torque and the engine output tends to result in the need for a stronger clutch, with a heavier clutch lever load. For the new CRF450R, revising the primary ratio has successfully achieved a smaller clutch system, with the lever load equivalent to the level for the previous model. The number of clutch discs has been reduced from 8 to 7, and the number of clutch plates has been reduced from 7 to 6. Increasing the clutch plate thickness from 1.6 mm to 2 mm has achieved heat resistance for the clutch plates that is at a level equivalent to that of the 7 plates installed on the previous model.

- Similar to the previous model, the engine of the new CRF450R enables the rider to choose from 3 types of modes for the engine characteristics and the throttle feeling of preference as necessary. With the 3 modes of “Standard,” “Smooth” and “Aggressive” available, dealing with wide-ranging conditions, situations and riding skills is possible. For the “Smooth” and “Aggressive” modes, use of the optional “HRC setting tool” enables changing the setting in accordance with the rider’s preference.

- For switches, the mode-related switches that were located on the right-hand side for the previous model are now concentrated in the switch housing on the left-hand side. A weight reduction by 41.5 grams has been achieved compared to the previous model as well. Switching among the different modes is possible anytime, as long as the throttle is turned off.

- For dimensions of the new CRF450R, we revised the dimensions of the previous model with the aim of improving traction performance. To make it easier to put the rider’s weight on the rear wheel and ensure more agility, the wheelbase has been shortened. Also for achieving more stability, which is seemingly contradictory to an agile feel, changes have been made to the front dimensions, with a lower center of gravity achieved for preventing the front end from lifting.

- To achieve outstanding acceleration and traction performance, both high rigidity and flexibility have been ensured for the main frame of the CRF450R, while reducing weight by 280 grams. With its tapered shape, the main pipe focuses on ensuring stability for the front area while increasing rear traction. The new frame helps promptly convey to the rider the road surface conditions and other critical information, contributing to very stable riding in the high-speed range.

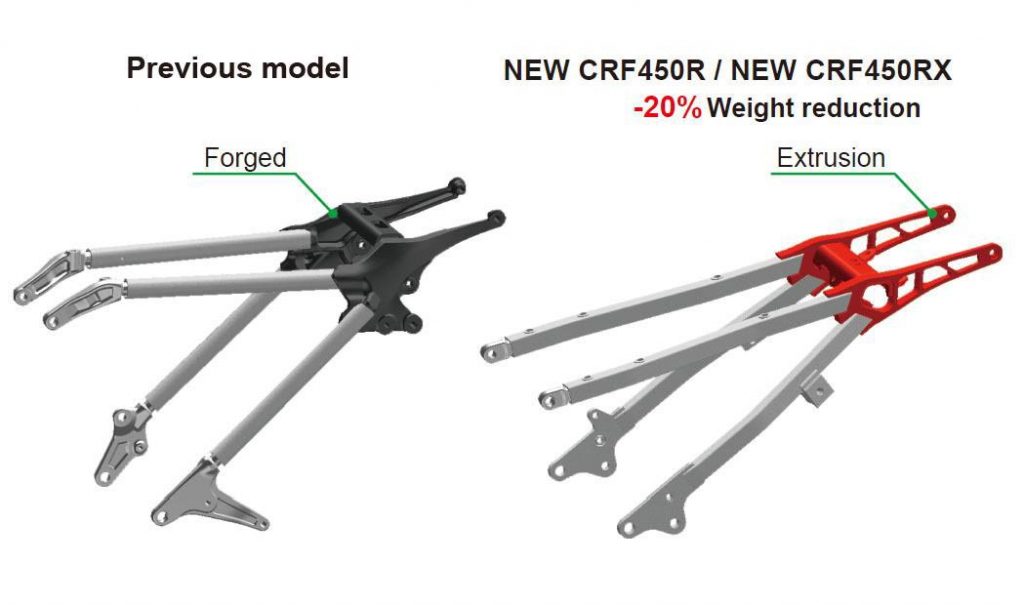

- A change has been made in the rear end of the subframe, from a forged product to an extrusion molded product. The resulting weight reduction by 20% in an area far from the vehicle’s center of gravity has contributed to further lowering the center of gravity. (Patent pending)

- For the fuel tank of the CRF450R, a switch was made from the resin tank of the previous model to a new tank made of titanium, achieving a weight reduction of 513 grams and contributing to the new model’s lower center of gravity. Also, the use of a flat tank cap has ensured a lower upper surface for the tank, better accommodating the riding style that allows for a smoother shifting of body weight necessary for the rider.

- To ensure that the front forks best match the new dimensions, an upgraded new coil spring suspension made by Showa Corporation is used. Compared to previous coil spring suspension systems, the compression piston diameter of Φ39 mm and main piston diameter of Φ25 and piston rod diameter of Φ14 ensure smooth movement while improving the run-through performance even over gaps.

- The layout of the rear cushion in the center at a low position has helped improve stability in riding, and the lighter and shorter swing arm has also contributed to reducing the weight under the brake springs. These measures have helped to enhance agility and traction performance.

- The styling design of the CRF450R shows an external appearance pared down to the utmost limit, comprising the parts that are needed for winning, with no room for any wastefulness. The lightweight and compact external parts have the shapes with minimum unevenness, for helping smoother shifts in riding position. The colouring offered is Extreme Red, inheriting the identity of Honda’s motocross model heritage, and asserting the individuality and presence that many people will recognize at once as the hallmarks of a Honda motorcycle.

- Honda have done away as much as possible with any joint lines and gaps between the parts comprising external components, to form seamless surface contours overall, to enable smooth shifting of the rider’s position while riding.

- For body design from the front view, renewing the radiator shroud has reduced the frontal projected area to decrease air resistance. By adopting a new shape for the front fender, the airflow while riding is efficiently guided inside the radiator shroud, enhancing the cooling effects. The opening width of the shroud has been narrowed compared to the previous model.