2020 Honda CBR1000RR Fireblade SP

The SP model of the 2020 Honda CBR1000RR Fireblade is the only variant to come to Australia and is priced at $49,999 +ORC. Two colour schemes are available in Australia, the HRC inspired Grand Prix Red (Tri Colour), or a more clandestine Matte Pearl Black.

Unlike the forecasts of many pundits the all new CBR1000RR Fireblade retains an in-line four-cylinder powerplant in 2020. This new model though certainly takes the Fireblade significantly upmarket, and with a price tag to match.

While the 2020 Fireblade does not share the V4 layout of the RC213V MotoGP machine, it does share the same short stroke design and exact bore dimensions as the machine that Marquez races, and the new Fireblade has been developed in close collaboration with HRC. No detail has not been thoroughly attended to.

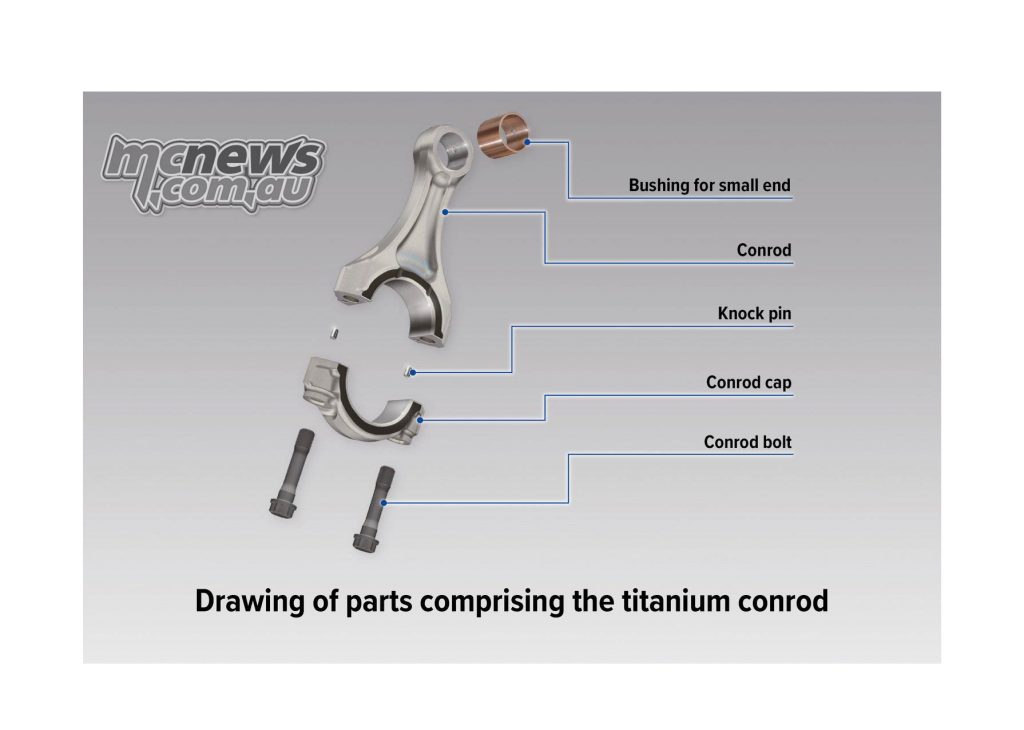

Forged A2618 aluminium (same material as used in RC213V-S) pistons swing off forged light-weight TI-64A titanium con-rods and slide a total of 48.5 mm inside an 81 mm bore towards a crescendo of 217 metric horsepower (160 kw) at 14,500 rpm, and 113 Nm at 12,500 rpm.

That is the largest bore size of any four-cylinder superbike and a dramatic difference to the 76 mm bore and 55.1 mm stroke of the previous machine. That’s also a claimed 25 more ponies than the outgoing SP model.

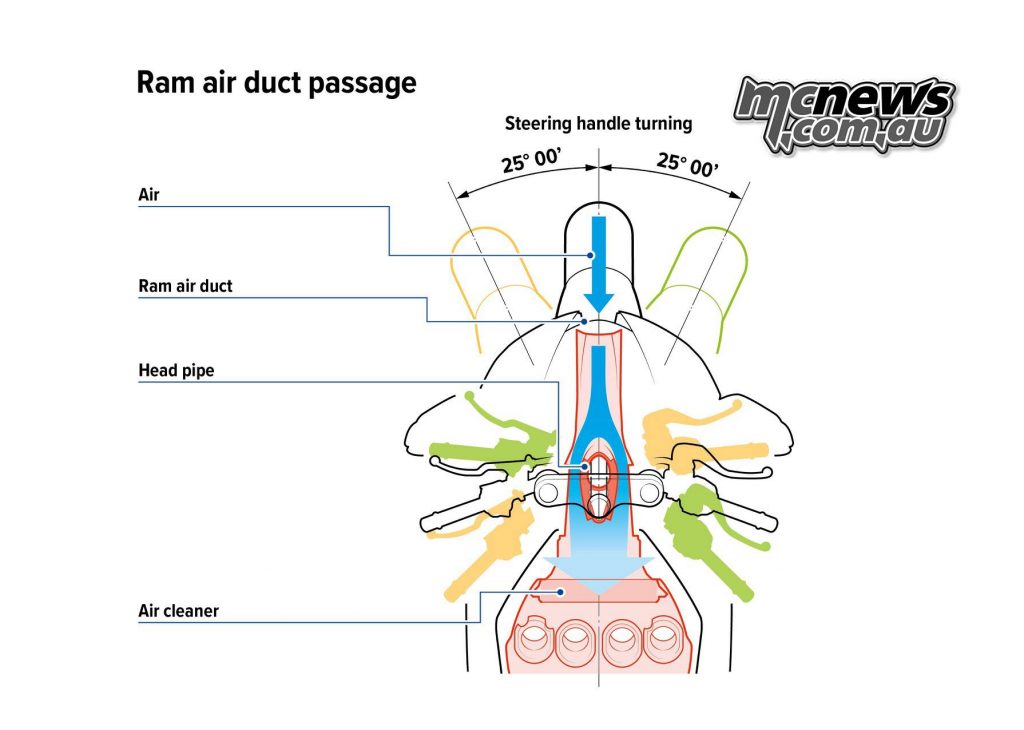

A ram-air duct in the front fairing feeds through the headstock directly into the airbox. The 4-2-1 exhaust downpipes are ovalized and the end-can has been developed in conjunction with Akrapovic.

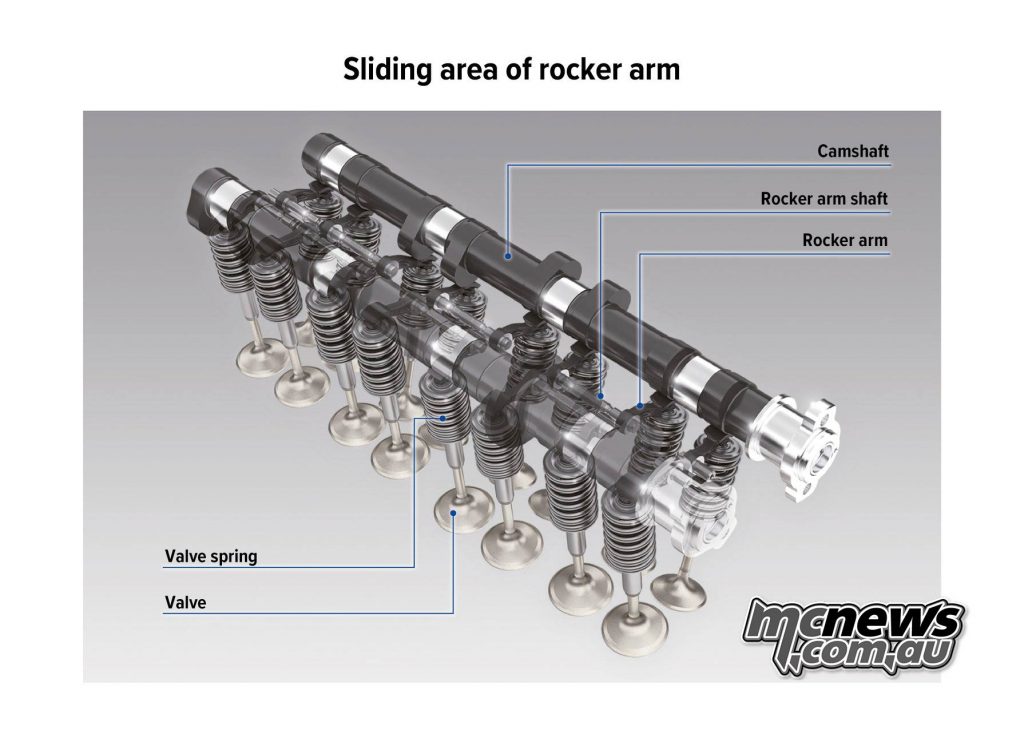

Honda say they have concentrated on fighting friction losses using technical solutions developed on their MotoGP bikes to make the new engine as efficient as possible.

32.5 mm inlet valves and 28.5 mm exhaust valves are operated by finger-follower rocker arms and cam lobes are coated with Diamond Like Carbon (DLC).

Honda claims is a first for a mass produced motorcycle that translates to a 35 per cent reduction in friction losses compared to non DLC coated lobes.

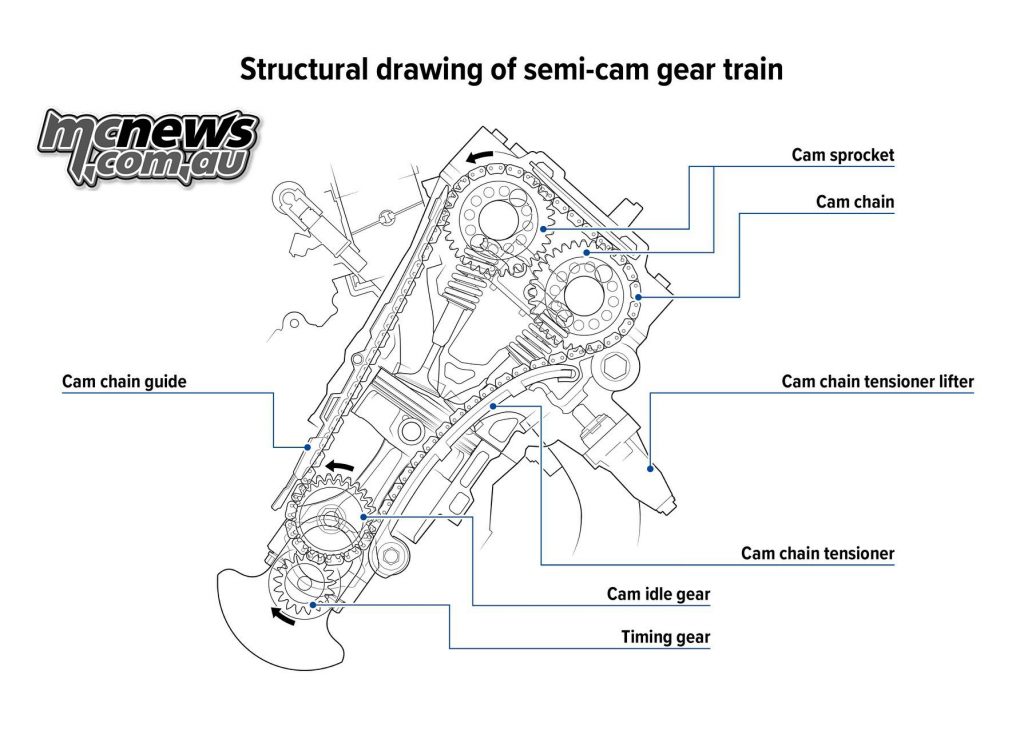

Those large valves are driven by what Honda calls a semi-cam gear train system that they have taken out a patent on.

Due to the high-lift cams the chain is driven from a timing gear located on the crank-shaft via the idle cam gear which makes the set-up shorter in length.

Connecting rod big-ends are also DLC coated while the small-end bushes are made of shaved C1720HT Beryllium copper for high-rpm reliability.

Despite their larger size than before, each piston is 5 per cent lighter than found in the previous model and the skirts are Ober coated (Telfon and Moylbendum base) and nickel-phosphorous plating for the pistin pin’s clip groove. All this HRC-like special bits inside the crankcases appear to be common across both models and are not limited to the SP.

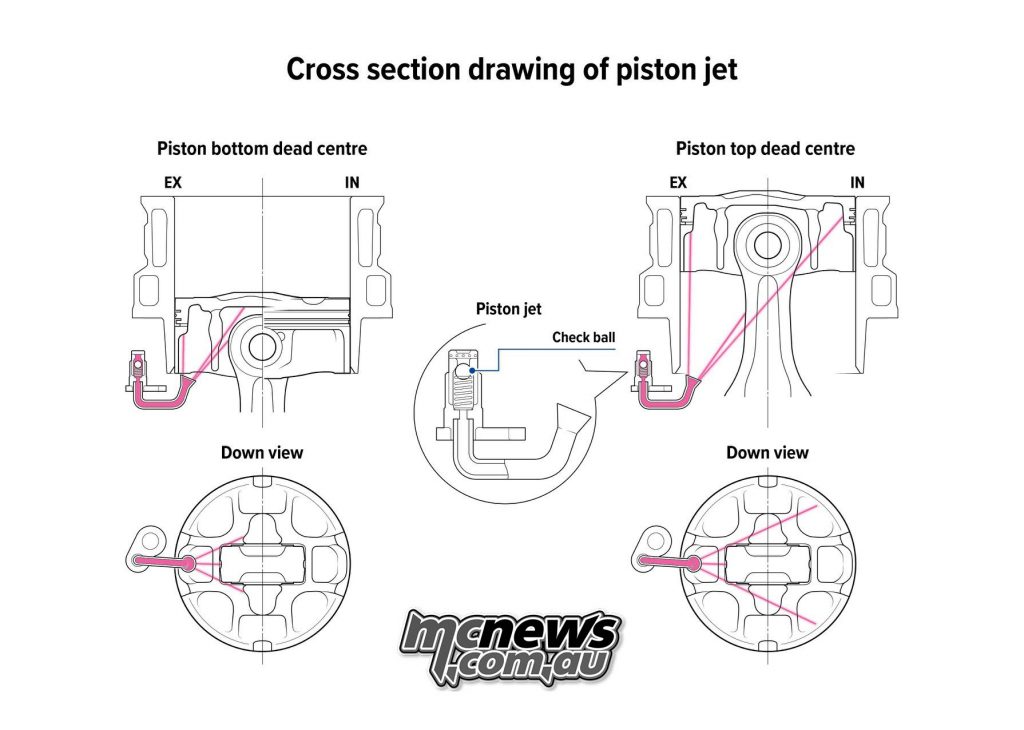

Helping to keep the temperature under control is a multi-point and multi-directional oil spray system which only operates at higher rpm.

When not required at lower rpm check-balls within the jets shut off the flow of oil to help maintain more oil pressure elsewhere.

A totally new aluminium diamond frame uses the rear of the engine as the upper shock mount; the swingarm is longer and based on the RC213V-S design.

The rigidity balance, weight distribution and steering geometry have been carefully adjusted for the increased engine output, in terms of front and rear grip levels, and feel for both.

In the standard model Showa’s 43mm Big Piston Fork (BPF) is matched to a fully-adjustable Showa Balance Free Rear Cushion Light (BFRC-L). At 330 mm the front discs are larger in diameter than before and worked by new Nissin four-piston calipers while the ABS is adjustable for track riding.

The SP gets new 43mm Öhlins NPX front forks to replace the NIX fork of the previous model and second-generation Öhlins Object Based Tuning interface (OBTi) offers finer control of settings front and rear. Brembo Stylema four-piston calipers are employed on the SP. The rear tyre is now sized 200/55-ZR17 on both machines.

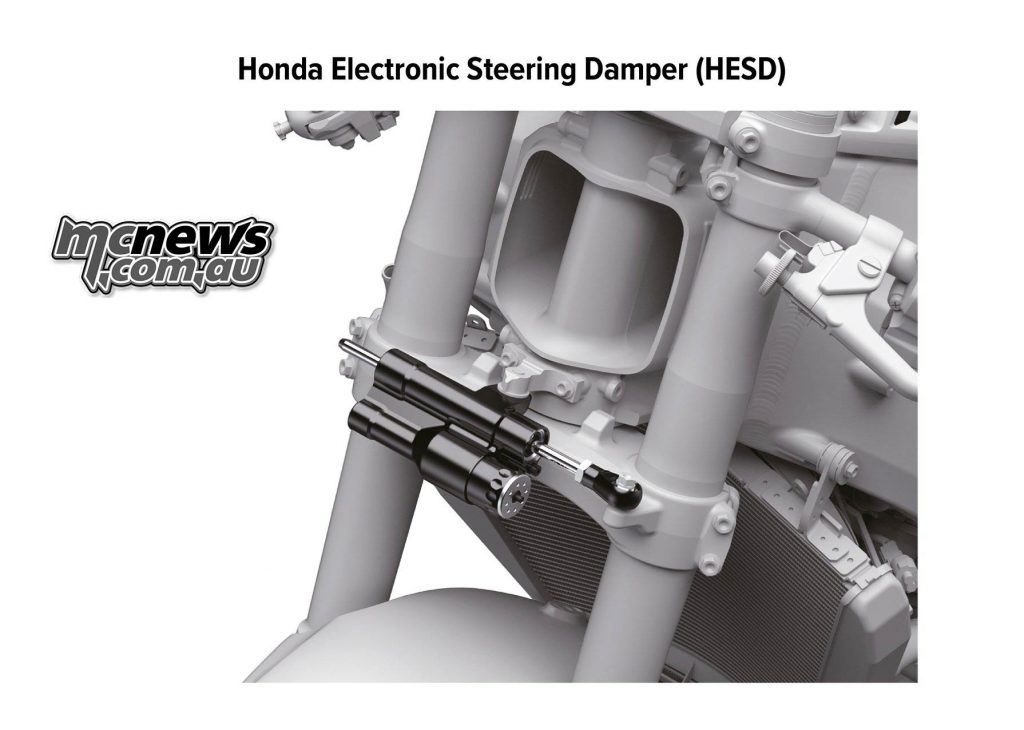

A six-axis Inertial Measurement Unit (IMU) provides accurate 3D estimation of riding dynamics and provides input to manage all of the electronic systems. It also controls the new rod-type 3-level Honda Electronic Steering Damper (HESD).

Honda’s RC213V MotoGP machine has lent some of its slippery aerodynamics to the CBR1000RR-R, including winglets to increase downforce and improve braking stability.

The riding position is also much more compact.

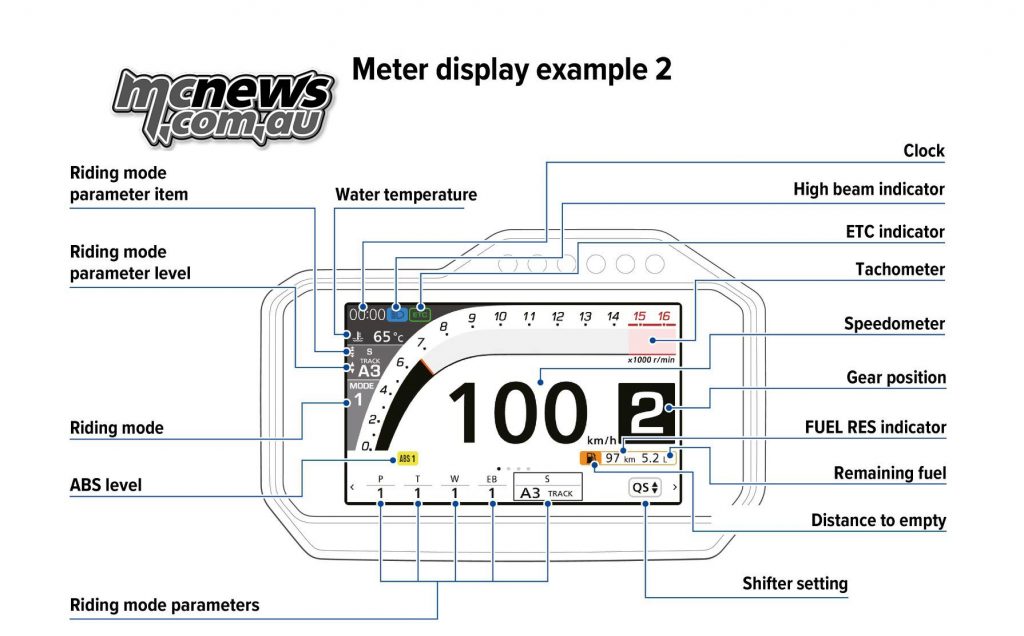

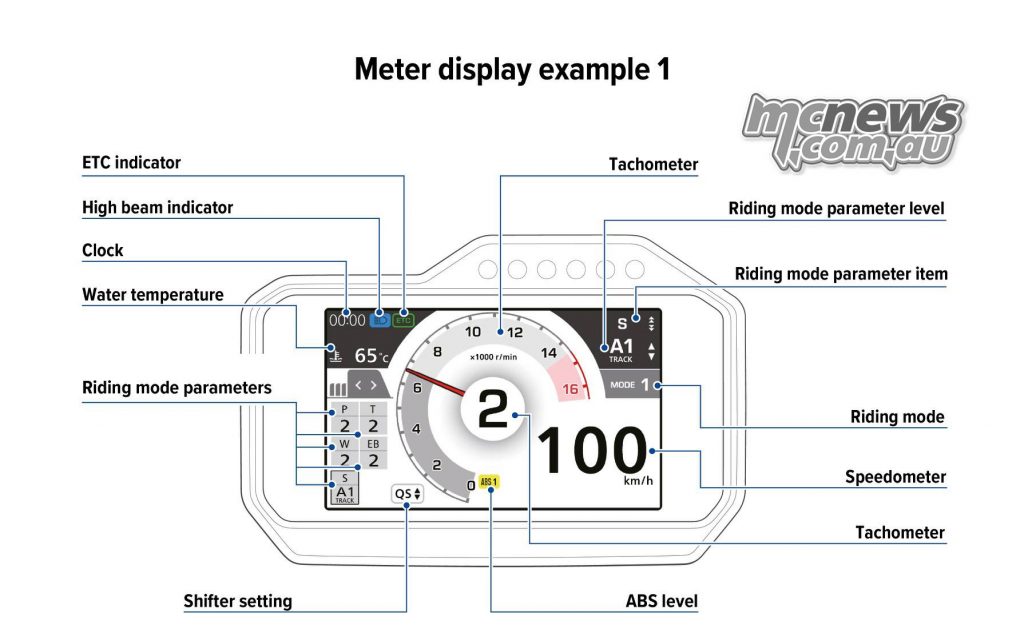

The fully customisable 5-inch TFT display offers intuitive control operated via a simplified four-way controller on the left handlebar.

Expected to appear in Australia some time during the second-quarter of 2020, the incredibly high-specification of the machine has led to a significantly higher price point than before. The 2020 Fireblade SP is priced at $49,999 + ORC and it is only this top level specification that will be sold in Australia.

2020 Honda CBR1000RR Fireblade Specifications

| Specifications | |

| Engine | |

| Type | Liquid cooled 4stroke 16valve DOHC, Inline 4 |

| Engine Displacement (cm³) | 999.9cc |

| No. of Valves per Cylinder | 4 |

| Bore ´ Stroke (mm) | 81mm x 48.5mm |

| Compression Ratio | 13.0 x 1 |

| Max. Power Output | 160 kW @ 14,500 |

| Max. Torque | 113 Nm @ 12,500 |

| Oil Capacity | 4.0L |

| Fuel System | |

| Carburation | PGMDSFI |

| Fuel Tank Capacity | 16.1L |

| Fuel Consumption | 16.0km/litre |

| Electrical System | |

| Starter | Electric |

| Battery Capacity | 126 YTZ7S |

| Drivetrain | |

| Clutch Type | Wet, multiplate hydraulic clutch with assist slipper |

| Transmission Type | 6 speed |

| Final Drive | Chain |

| Frame | |

| Type | Aluminium composite twin spar |

| Chassis | |

| Dimensions (L x W x H) | 2100 x 745 x 1140 mm |

| Wheelbase | 1455 mm |

| Caster Angle | 24o |

| Trail | 102 mm |

| Seat Height | 830 mm |

| Ground Clearance | 115 mm |

| Kerb Weight | 201 kg |

| Suspension | |

| Type Front | Showa Telescopic inverted fork with an inner tube diameter of 43 mm, and a Big Piston Front Fork with preload, compression and rebound adjustment, 120 mm stroke. SP – Telescopic inverted fork with inner diameter of 43mm and Ohlins NPX Smart-EC with preload, compression and rebound adjustments. 125 mm stroke. |

| Type Rear | Rear Suspension – Unit Pro-Link with gas-charged HMAS damper featuring 10-step preload and stepless compression and rebound damping adjustment, 137 mm stroke. Showa BFRC-Light SP – Pro-Link with gas-charged Ohlins TTX36 Smart-EC damper featuring preload, compression and rebound damping. 143 mm stroke. |

| Wheels | |

| Rim Size Front | 17 inch x 3.5 |

| Rim Size Rear | 17 inch x 6.0 |

| Tyres Front | 120/70ZR17 Pirelli Diablo Supercorsa SP – Bridgestone RS11 |

| Tyres Rear | 200/55ZR17 Pirelli Diablo Supercorsa SP Bridgestone RS11 |

| Brakes | |

| ABS System Type | 2 Channel |

| Front | 330mm disc with radial mount 4 piston Nissin caliper, SP 330mm disc with 4-piston Brembo caliper |

| Rear | 220mm disc with 2 piston Brembo caliper |

| Instruments Electronics | |

| Instruments | TFT LCD |

| Security System | HISS |

| Headlight | LED |

| Taillight | LED |

Getting more in depth with the new Fireblade

Air is fed into the engine via a ram-air duct located at the high-surface pressure tip of the front fairing; the size of its aperture is equivalent to that of the RC213V MotoGP machine.

A ribbed ‘turbulator’ to the right, left and above the duct entrance ensures maximum induction of moving air with minimal impact on handling. The draft angle of the aperture’s interior wall maintains flow under high-speed and acceleration.

To maintain stable performance across a wide speed range, pressurised air takes a straight shot through the headstock, around the steering stem and into the airbox. This smooth path is made possible by the application of Honda’s Smart Key system (dispensing with a traditionally-mounted ignition barrel), and a steering angle of 25°.

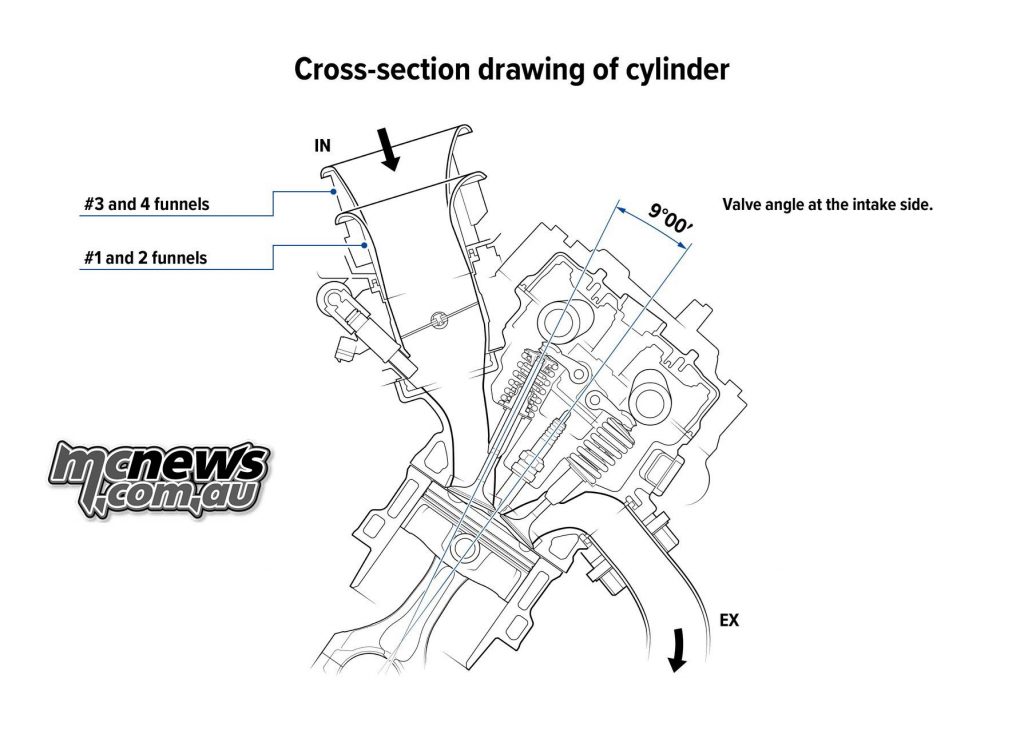

The ‘dirty’ side of the air filter has been enlarged to lower airflow speed and it’s also 25% bigger than the previous design and angled for an even flow. On the ‘clean’ side, filtered air changes direction into the largest volume of the airbox and – along with fuel from the upper injector – feeds to an eccentric bell-mouth funnel. The result is reduced drop in intake air pressure – and more efficient breathing for more performance.

To draw the volume of air needed the throttle body diameters have been enlarged from 48 to 52mm. An oval internal cross-section makes for smooth flow – and further reduces intake pressure drop – from the throttle butterfly valves to the inlet valves.

The valve angle on the intake side has been reduced from 11° to 9°. This change improves combustion efficiency by reducing the surface area of the combustion chamber, and gas flow efficiency of the intake ports is increased by approximately 2%.

The port volume (the capacity between throttle butterfly valves and intake valve seat) has been reduced 13% to improve throttle response. And the throttle shaft is now constructed from highly rigid stainless steel (as opposed to brass) reducing deflection and operational friction, putting a much more direct connection into the rider’s right hand.

Mirroring the intake side, the four exhaust downpipes have optimised diameters and an oval cross section to improve gas flow. The catalyser unit is 10mm larger in diameter to reduce exhaust pressure drop, and careful adjustment of wall thickness has minimised any weight increase.

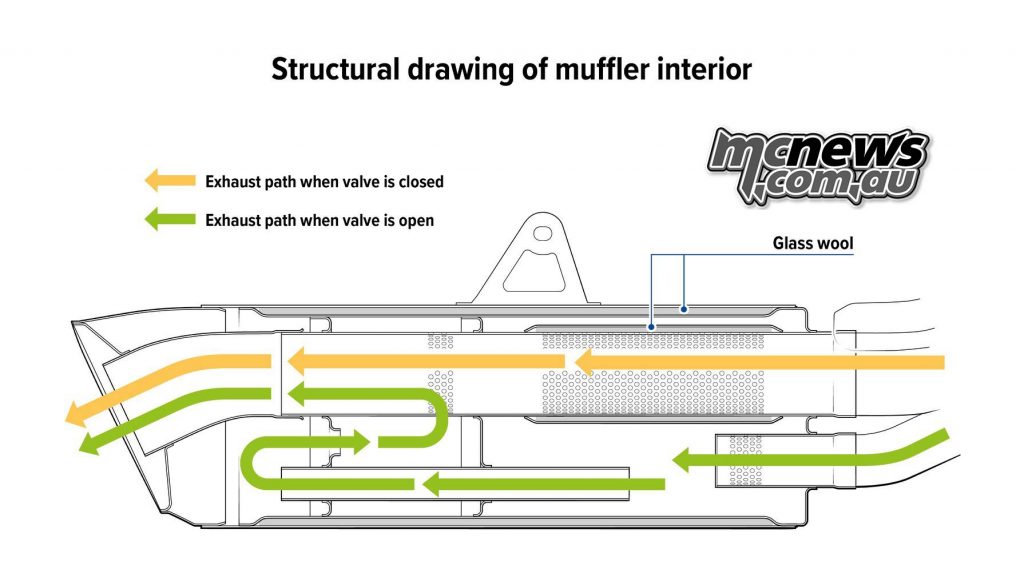

Akrapovic partnered in development of the exhaust end-can. Constructed from titanium, its small physical size and light weight contribute to mass centralisation and right-side lean angle.

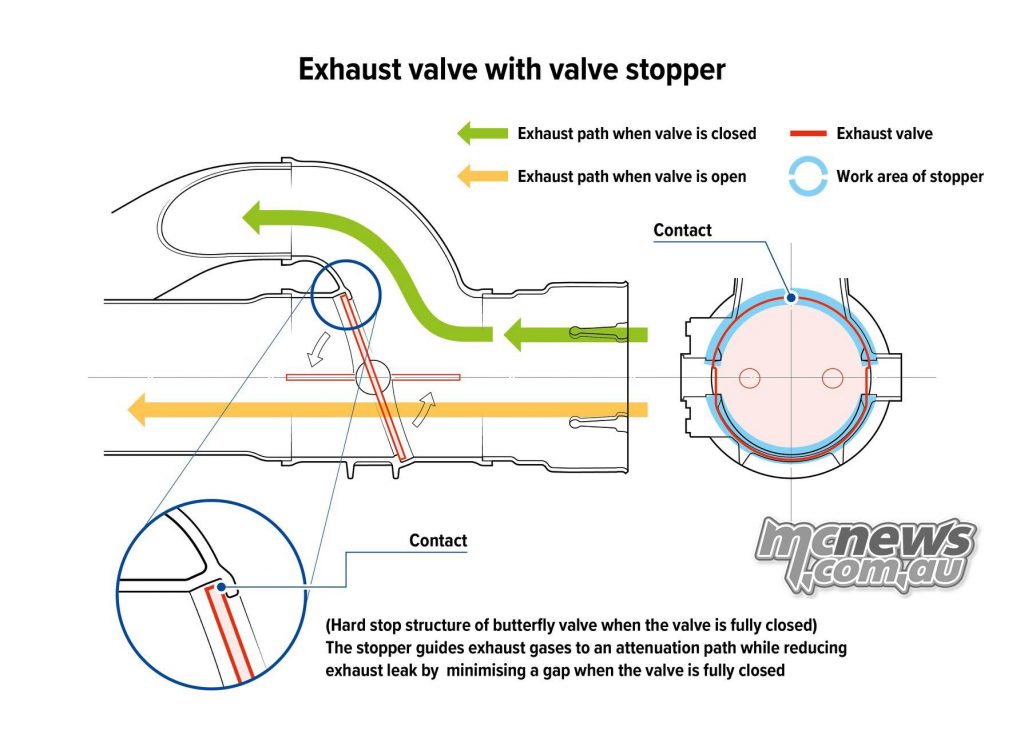

The exhaust valve was also designed with Akrapovic to deliver both low-rpm torque and high-rpm power; a valve stopper (patent-pending) stops exhaust-gas leak when closed while also reducing noise, allowing total end-can internal volume to reduce by 38% compared to the outgoing design.

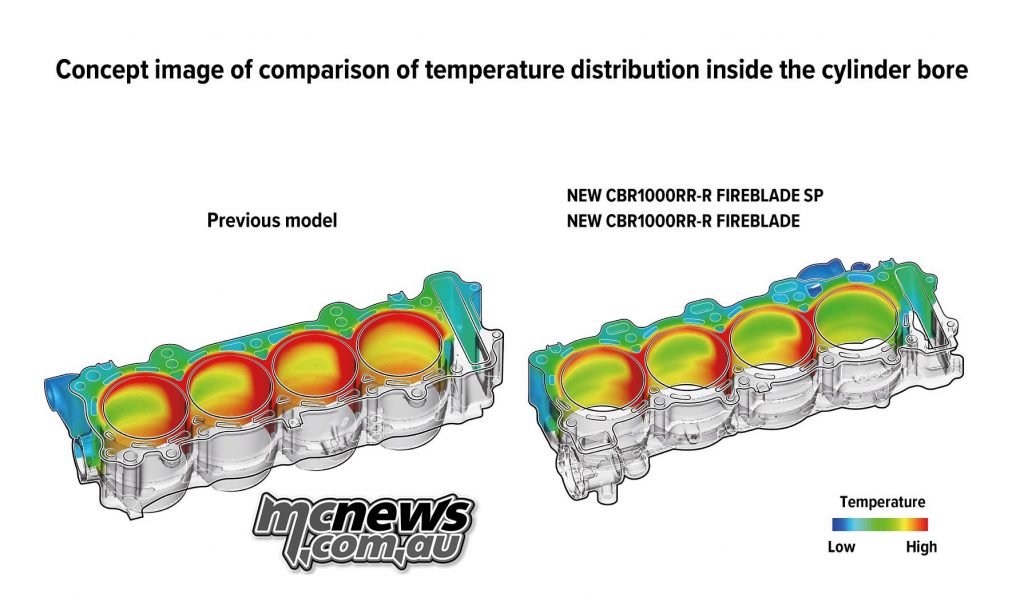

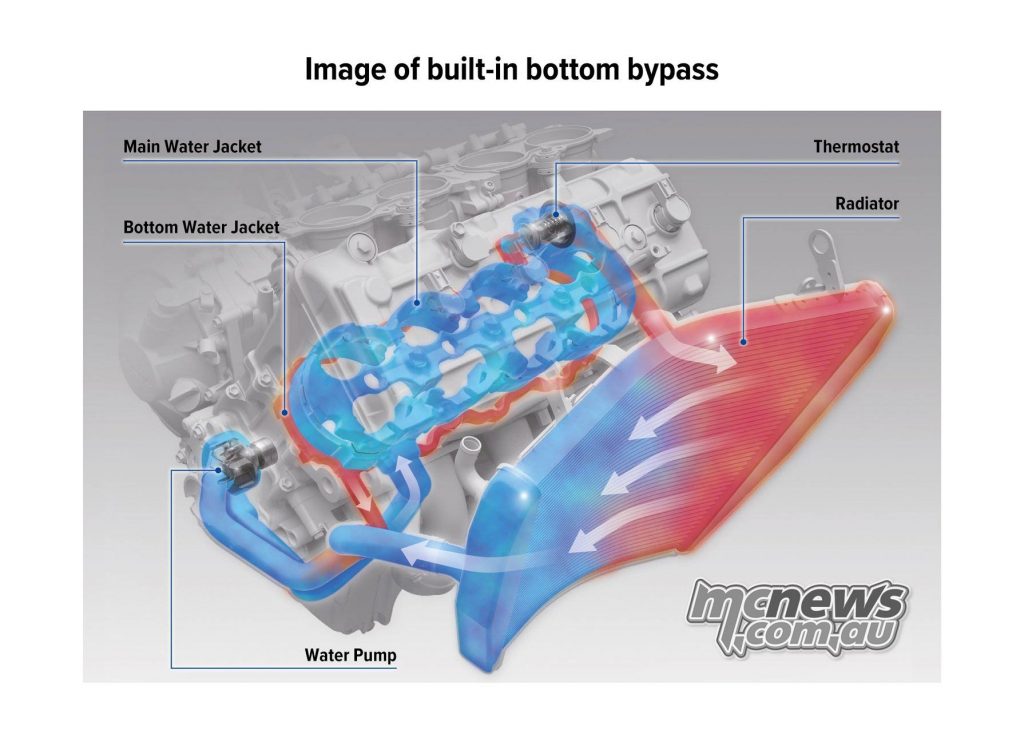

Minimising friction elsewhere in the RR-R engine was a key focus in obtaining the increase in rev-range. To reduce bore distortion (and thus friction), the cylinder features a patent-pending built-in bottom bypass. This system circulates cool water from the radiator into the main water jacket, while the area below uses non-cooled water. The net effect is a lower, and more even temperature at all points across the bores compared to the previous engine. An external hose is also eliminated.

To reduce width the engine is started by rotation of the clutch main shaft rather than the crankshaft. Patent-pending, this design allows for a more compact crankshaft while double use of the primary driven gear (which itself is smaller, with fewer teeth) to also transmit rotation from the starter motor saves space; the engine is shorter in length thanks to reduction in distance between the crankshaft, counter shaft and main shafts. The rear of the engine block also now serves as the upper shock mount.

The 17YM CBR1000RR was the first in-line four-cylinder engine from Honda to use Throttle by Wire (TBW). Derived and developed from the system used by the RC213V-S, it controls the throttle butterfly valve angle (relative to input from the throttle) to provide a linear delivery and puts precise throttle control – and a natural feel – in the rider’s right hand.

For the CBR1000RR-R, TBW has been improved for faster response through a range of part throttle applications – such as gradual opening on corner exit – to minimise any delay in torque delivery.

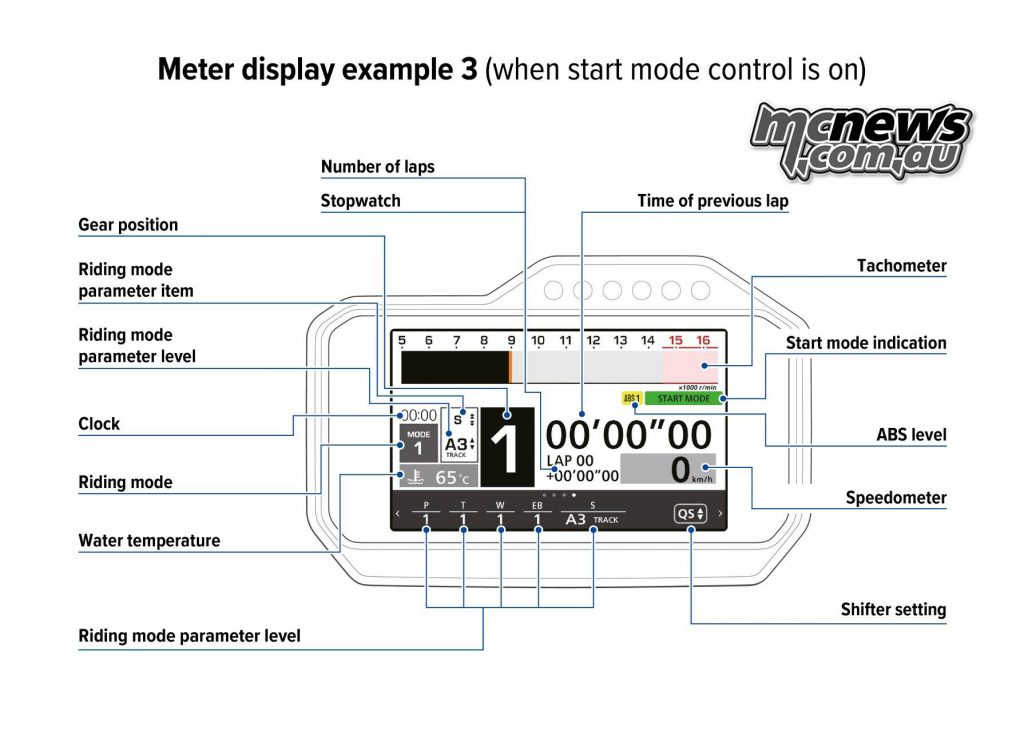

There are three default riding modes, with options to change engine output and character (see diagram). Power (P) operates through levels 1-5 with 1 giving ultimate outright power. Engine Brake (EB) manages performance on a closed throttle through levels 1-3, with 1 being the strongest engine braking and Wheelie (W) through levels 1-3 (plus off) with 1 giving the weakest intervention.

Wheelie control uses information gathered by the IMU on the RR-R’s pitch angle, along with front and rear wheel speed sensors to maintain torque and deal with the wheelie without sacrificing forward drive.

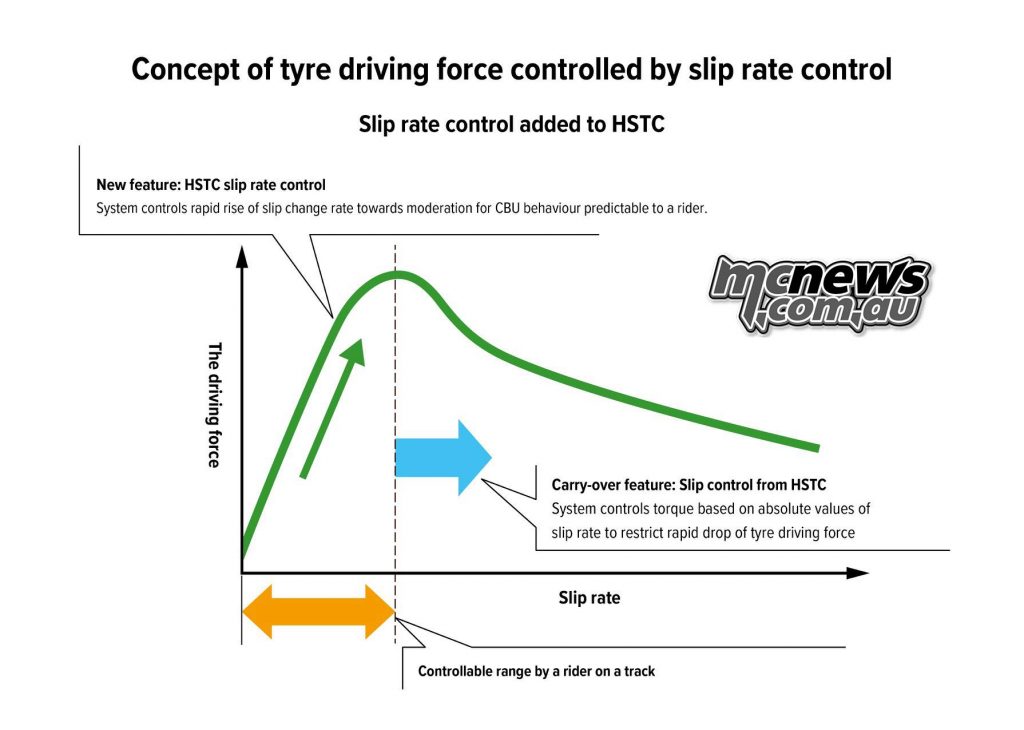

Honda Selectable Torque Control (HSTC) adjusts through 9 levels (plus off) with 1 giving weakest intervention. It has been optimised for the RR-R and now adds slip rate control (when the slip change rate based on ratio of front/rear wheel speeds exceeds predetermined values) to moderate rapid wheel spin (see diagram). In conjunction with the existing outright slip control, HSTC is smooth in operation while delivering maximum confidence for the rider.

The CBR1000RR-R is also equipped with Start Mode for race starts. It limits engine rpm at 6,000, 7,000, 8,000 and 9,000rpm set-points, even with a wide-open throttle, letting the rider focus on clutch release (and lights) alone.

The reduction in physical size of the CBR1000RR-R’s engine opened up new packaging options around it for the new frame and swingarm – with completely revised geometry. The goals? Even more accurate high-speed steering, improved stability under acceleration and braking, and feel for front and rear grip on the limit. And at the very highest level of competition.

The diamond frame is constructed from 2mm aluminium and allows much more accurate tuning of the rigidity balance; in manufacture, after the four main frame components are welded, the engine now mounts in six locations improving machine handling. Vertical and torsional rigidity are increased by 18% and 9%, with horizontal rigidity decreased by 11% – all aimed at producing maximum levels of feel.

Wheelbase is now 1,455mm, with rake and trail of 24°/102mm (from 1405mm, 23°/96mm) for stability. Wet weight is 201kg. There have also been considerable changes to balance and centre of gravity; the crankshaft is 33mm further from the front wheel spindle and raised 16mm. This evens out weight distribution, while the higher c-of-g improves side-to-side agility.

The swingarm – stamped out from 18 individual thicknesses of aluminium and as used by the RC213V-S – is 30.5mm longer, at 622.7mm, but weighs exactly the same as the previous design. Its horizontal rigidity is reduced by 15%, with vertical rigidity maintained to generate grip and feel.

For optimum frame rigidity (and to save weight) the top mount of the Pro-Link rear suspension attaches to the rear of the engine block via a bracket, doing away with the upper cross-member. This also isolates the rear wheel from the headstock, improving high-speed stability and feel for rear wheel traction.

Round, thin-wall aluminium tubing forms the minimal subframe. It also mounts to the frame from the top (rather than sides) to narrow the area around the rear of the fuel tank and seat, making for a compact – and aerodynamically efficient – riding position. Seat height is 830mm, with the handlebar position pushed forward (for leverage) and foot pegs moved rearward, and up.

A Bosch six-axis Inertial Measurement Unit (IMU) replaces the five-axis unit of the previous design; this allows more accurate calculation of pitch and roll for even more precise control of bike behaviour.

The CBR1000RR-R is also equipped with Showa’s new Honda Electronic Steering Damper (HESD). A lightweight through-rod design that mounts on the bottom of the steering stem and attaches to the bottom yoke, HESD is controlled by input from the wheel speed sensors and IMU; 3 levels of control are available.

With its large damping volume, the Showa 43mm Big Piston Fork (BPF) inverted telescopic fork effectively reduces hydraulic pressure generated under compression and extension. This results in reduced play during the initial stroke and smoother damping, maximising tyre contact with the tarmac. Spring preload and rebound/compression damping are fully adjustable and for the RR-R the fork is longer in length than before, allowing more freedom for geometry changes track-side.

The rear shock is a fully adjustable Showa Balance Free Rear Cushion Light (BFRC-Light). Instead of a conventional single-tube layout, BFRC-Light uses a double-tube design: the damper case and an internal cylinder. The damper piston has no valves – instead the damping force is generated as displaced oil passes through a separate damping component.

This allows pressure changes within the shock to be smoothly controlled, damping response and reaction to be improved, and damping force to function smoothly during load input. Moreover, damping weight is generated consistently when switching from rebound to compression due to even pressure changes.

SP Suspension

The CBR1000RR-R SP is also equipped with Showa’s new Honda Electronic Steering Damper (HESD). A lightweight through-rod design that mounts on the bottom of the steering stem and attaches to the bottom yoke, HESD is controlled by input from the wheel speed sensors and IMU; 3 levels of control are available.

Second-generation semi-active Öhlins Electronic Control (S-EC) is featured on the RR-R SP. The 43mm Öhlins NPX fork uses a pressurised damping system to minimise cavitation, resulting in more stable damping control and improved bump absorption at race-track speeds. Feel for front tyre grip is also enhanced. Its length also offers greater freedom for geometry changes. The shock is an Öhlins TTX36 Smart-EC unit.

In conjunction with the hardware upgrade the Öhlins Objective Based Tuning interface (OBTi) now offers much finer suspension adjustment front and rear; both can be set independently from the default settings and 3 individual modes can be set and stored allowing the rider to configure multiple settings for a track, and switch instantly while riding.

New Nissin four-piston radial mount front brake calipers are fitted, which offer more rigidity with reduced weight, and grip 10mm larger 330mm diameter discs. Braking power is improved for track use; the 5mm disc thickness also dissipates heat more efficiently. The rear brake caliper is the same Brembo unit used by the RC213V-S.

SP Brakes

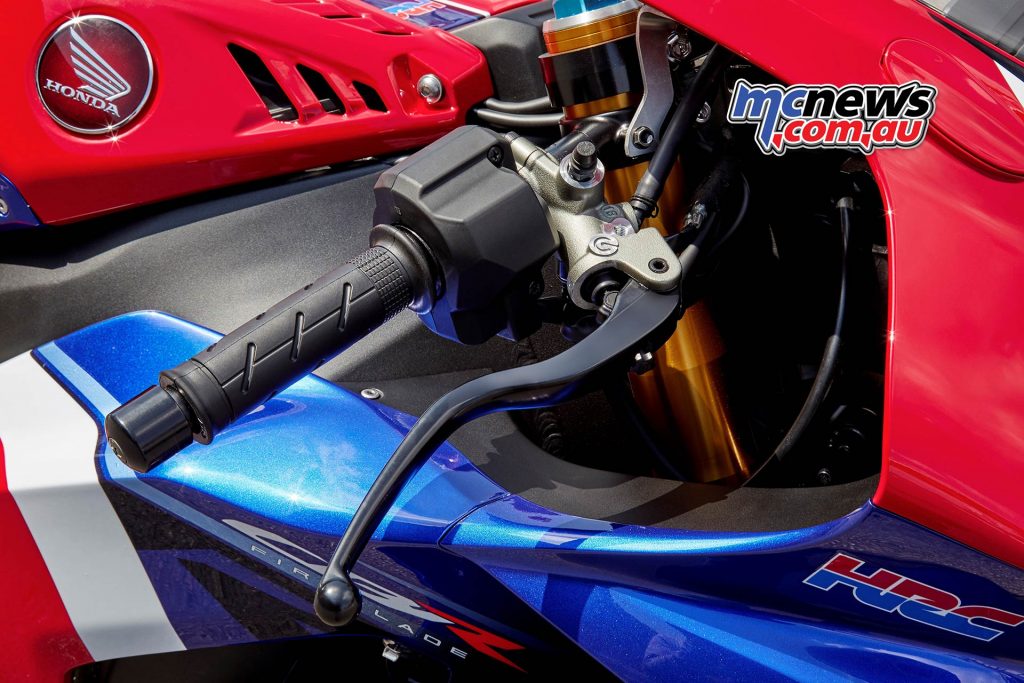

New Brembo Stylema four-piston radial mount brake calipers are operated by a Brembo master cylinder and brake lever.

Rear lift control and ABS-managed brake force relative to lean angle were a feature of the previous design. For the CBR1000RR-R the system gains two switchable modes; SPORT mode focuses on road-riding performance, with high brake force and less pitching, while TRACK mode offers performance in braking from much higher circuit speeds.

The rear 17-inch rim has new hub geometry, to save weight while maintaining rigidity and mounts a 200/55-ZR17 sized tyre (from 190/50-ZR17) minimising the change in chassis geometry when going from street to track rubber. The front rim mounts a 120/70-ZR17 tyre.

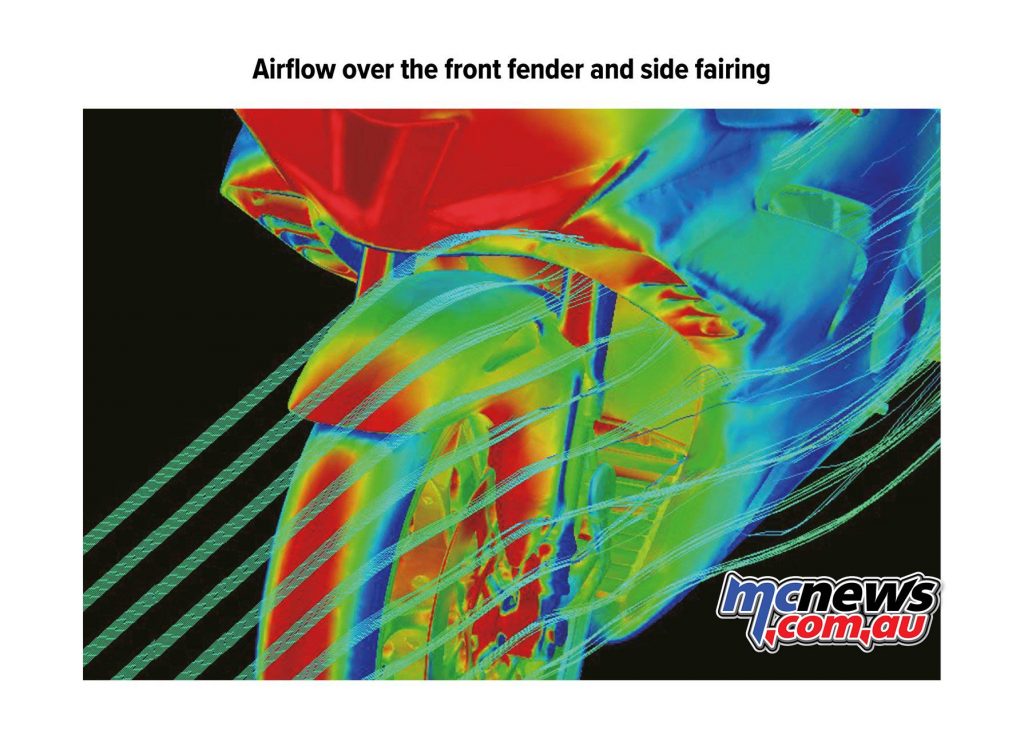

Alongside its new engine and chassis the CBR1000RR-R has an aggressive new fairing design. It’s no mere styling exercise however; the drivers in development were to create a class-leading drag coefficient (with a tucked-in rider under track conditions) and restrict lift under acceleration while improving braking stability.

The first part of the process was to lower the fuel tank cover by 45mm (compared to the previous design) decreasing the frontal area with the rider prone. At a 35° angle the screen smoothly channels airflow from the upper fairing over the rider and seat cowl, which itself presents the minimum possible drag resistance. The left and right upper fairing slits reduce yaw and roll resistance while turning.

To make steering easier a convex surface on each side of the front mudguard moves air flow away from the front wheel, smoothly directing it to the fairing sides. Cooling air for radiator and oil cooler has been optimised by aerodynamic management of both velocity and pressure of air flowing from the tyre.

The lower fairing has been extended close to the rear tyre, and shaped to channel air downward. This has two effects: in dry conditions, less air hits the tyre, lowering drag; in the wet, less water hits the tyre, improving grip. To let air flow around the rider’s feet with minimum resistance the sides of the rear hugger are carefully shaped while its upper side is cut-out to vent air that channels up from underneath either side of the swingarm, decreasing rear lift.

The net result of all this work, with the CBR1000RR-R in stock race trim, is a best-in-class drag coefficient value of 0.270.

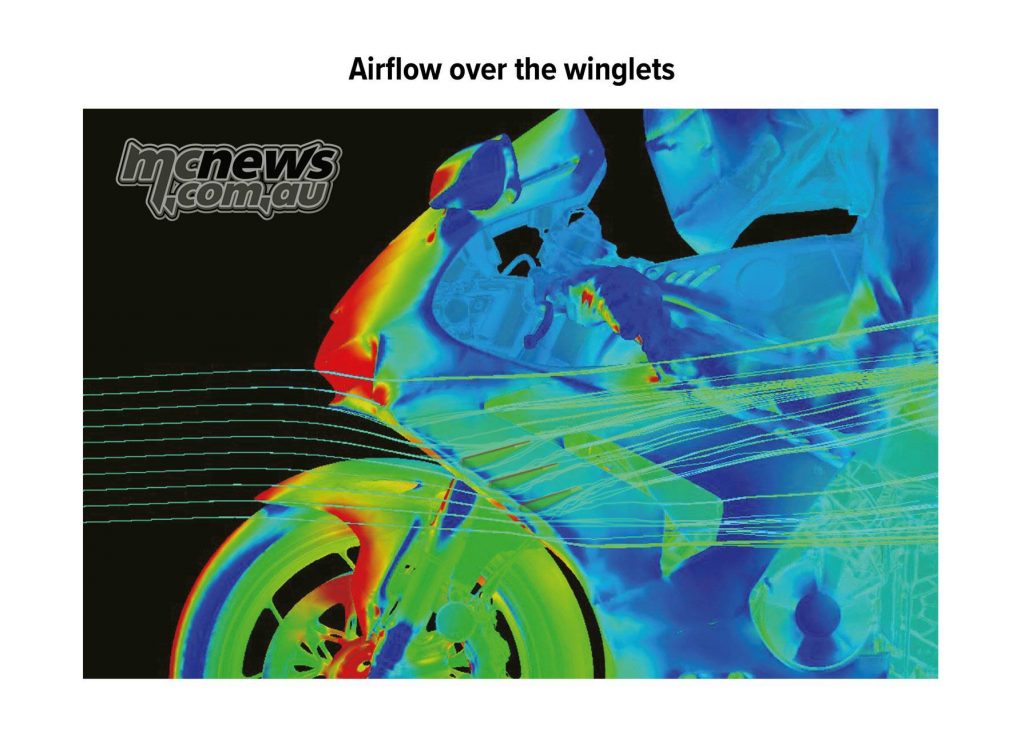

To generate downforce at track speeds – and maintain the smallest possible frontal area – the CBR1000RR-R employs winglet structures that effectively generate the same downforce as the 2018 RC213V MotoGP machine. The results are a reduction in wheelies under acceleration and increased stability on braking and corner entry.

Three wings are arranged in a vertical line inside both left and right fairing ducts. This arrangement (vertically deep and longitudinally shallow) has no detrimental effect on yaw and roll ability during corner entry. And the consistent distance between the trailing wing tips and the inner fairing wall limits separation of the airflow, producing maximum downforce.

The wing angle balances opposing right/left downforces from the dihedral and twist angles when yaw occurs through a corner, for stable behaviour. Flow speeds over the top and below the wings differ to prevent air getting ‘trapped’ on the fairing sides and affecting handling.

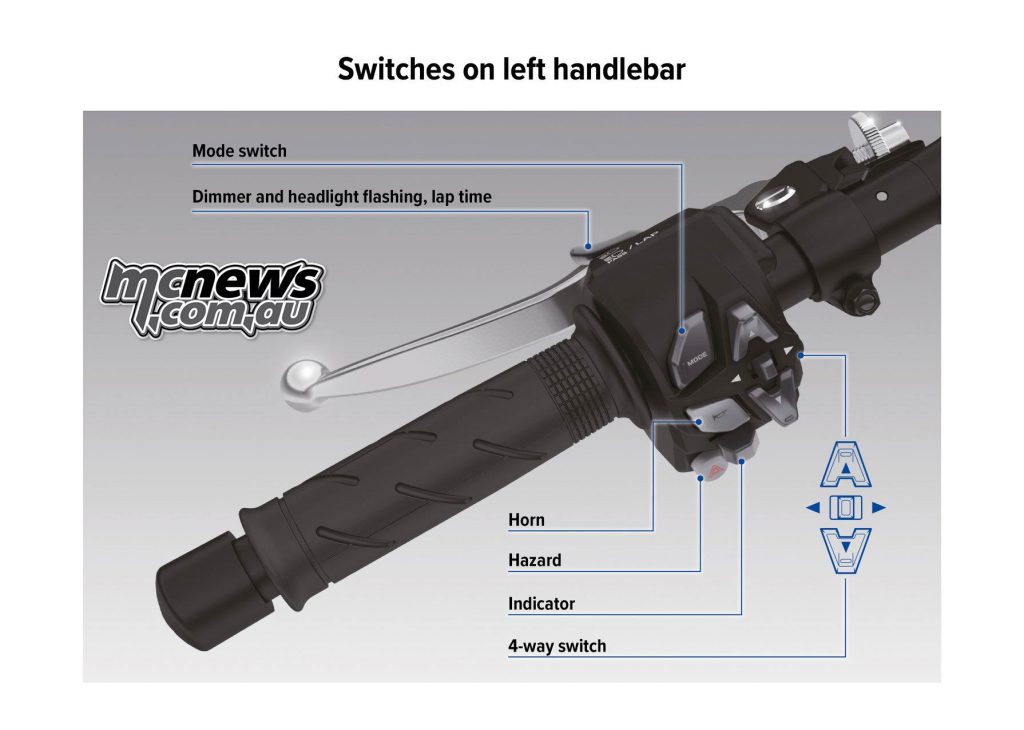

For full and intuitive control of the CBR1000RR-R’s systems the full colour 5-inch TFT screen is larger and with higher resolution. It’s fully customisable to show exactly what the rider wants to see. The compact left hand switchgear houses a four-way switch. Fast and easy to use, the top/bottom buttons set riding mode parameters, while the left/right buttons cycle screen display information.

Honda’s Smart Key System has been added. The ignition now operates without having to insert a key, as does handlebar lock. This is both convenient in day-to-day use and has allowed use of a competition-style top yoke while freeing up optimum space for the ram air system.