New 2017 Suzuki GSX-R1000R and GSX-R1000

Two all-new models: GSX-R1000 and GSX-R1000R – More than 600 new parts and components

- Max Power: 148.6kW (202ps) @ 13,200rpm

- Max Torque: 117.6Nm @ 10,800rpm

- Wet Weight: 202kg & 203kg (GSX-R1000R)

- Ride by wire throttle bodies

- Suzuki Racing Variable Valve Timing (VVT) system

- Suzuki Racing Finger follower valve train system

- Suzuki Top-feed injectors (S-TFI)

- Suzuki Exhaust Tuning Alpha (SET-A)

- Inertial measurement Unit (IMU) advanced electronic management system

- Motion Track Traction Control (10-levels)

- Suzuki Drive Mode Selector (S-DMS) 3-modes

- Motion Track Brake System

- Titanium exhaust muffler

- All new-aluminium frame (10% lighter)

- LED Headlight, taillight, registration plate light and indicators

- Suzuki Easy Start System – Low RPM assist

- Brembo 320mm hybrid mounting system front discs

- Lightweight 6-spoke cast aluminium wheels with Bridgestone RS10 radial tyres

- Full LCD multi-function instrument panel

- GSX-R1000: Showa BPF forks and Showa rear shock

- GSX-R1000R: Showa Balance Free Forks (BFF) and Balance Free Lite rear shock, Quick shift system (Up & Down), Launch Control, LED daytime running lights and lightweight battery

- Availability: Q2, 2017 –Final colours, specs and pricing TBC

It has been three decades and more than a million sold since the GSX-R line was born. A decade and a half since the first GSX-R1000 (K1) changed the open sportsbike class forever.

Now, the 6th-generation GSX-R1000 is redefining the definition of “Superbike”. It embodies the life work and professional ambition of Suzuki engineers who are extremely passionate about the GSX-R brand and its place in motorcycle history. A team who love riding and racing, enthusiasts who were determined to restore the GSX-R1000 to its rightful place as top dog.

Put simply -It is the most powerful, hardest-accelerating, cleanest-running GSX-R ever built

It is also the most compact, the most aerodynamic and the best-handling GSX-R1000 ever, with smoother throttle response and better combustion efficiency. With a supremely effective electronic engine management system that doesn’t require a degree in engineering to understand and doesn’t require constant adjustment by a squad of computer technicians to work.

Above all, it is a GSX-R. By definition, it is built to perform and be reliable, and designed to help make riders, better riders. It has been engineered using the experience gained during 30 Years of domination in production-based Superbike, Superstock and Endurance races worldwide, combined with new proprietary technology developed in the MotoGP World Championship.

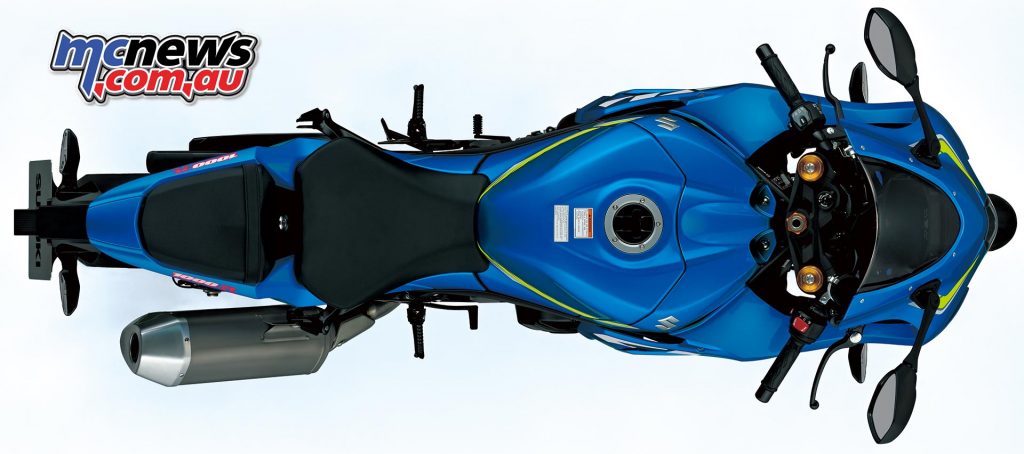

Available in two versions, the standard GSX-R1000 and the limited-production GSX-R1000R. Both versions come fully equipped for the street, but remove the mirrors, the registration plate and tape-up the lights and they’re also ready for closed-course dominance.

The new GSX-R1000 incorporates more than 600 new parts and components, but the proud, traditional, core engineering philosophy of producing the best possible performance motorcycle has been inherited by the latest GSX-R1000.

Throughout 30 years of GSX-R development, Suzuki engineers have focused on the fundamentals that make a great sportsbike. Those fundamentals can be distilled down into three simple words: Run. Turn. Stop. The design brief was to make the new GSX-R1000 run better, turn better and stop better than any other sportsbike before it.

In short, develop a new, unmatched combination of reliability, durability, usability and overall performance with excellent racing potential in a package that works as well for street riders as it does for track-day riders and amateur or professional racers.

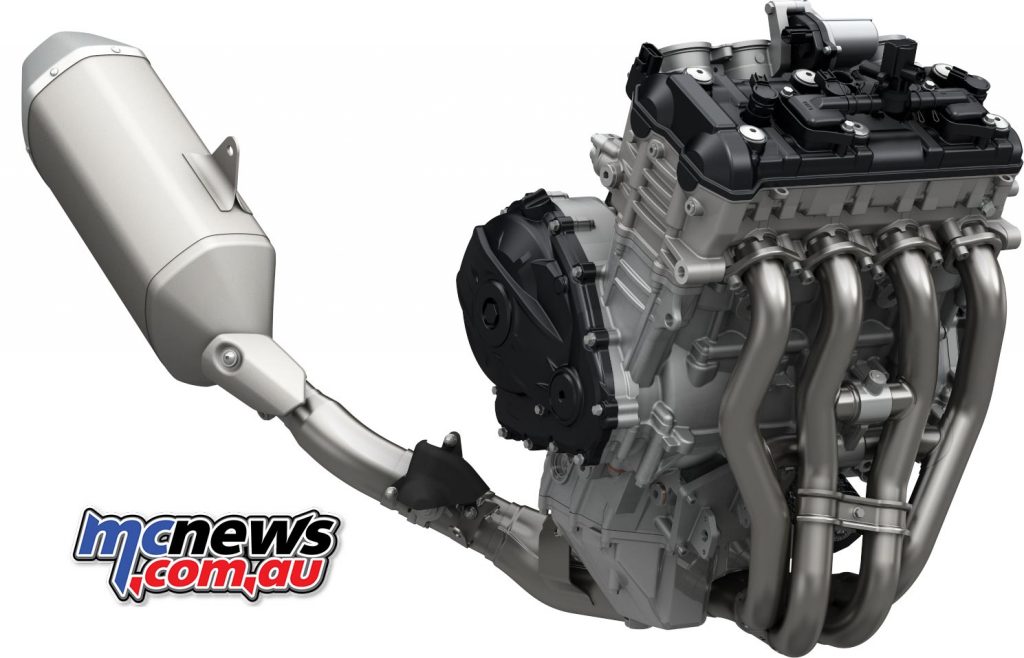

The design team quickly settled on the basic engine design goals. The new engine would rev higher and make more peak horsepower, while maintaining excellent low-to-mid-range power and drive. It would be a compact and lightweight inline four cylinder, DOHC with chain cam drive and four titanium valves per cylinder set at narrow angles, with a more over-square bore/stroke ratio, a higher redline limit and a higher compression ratio.

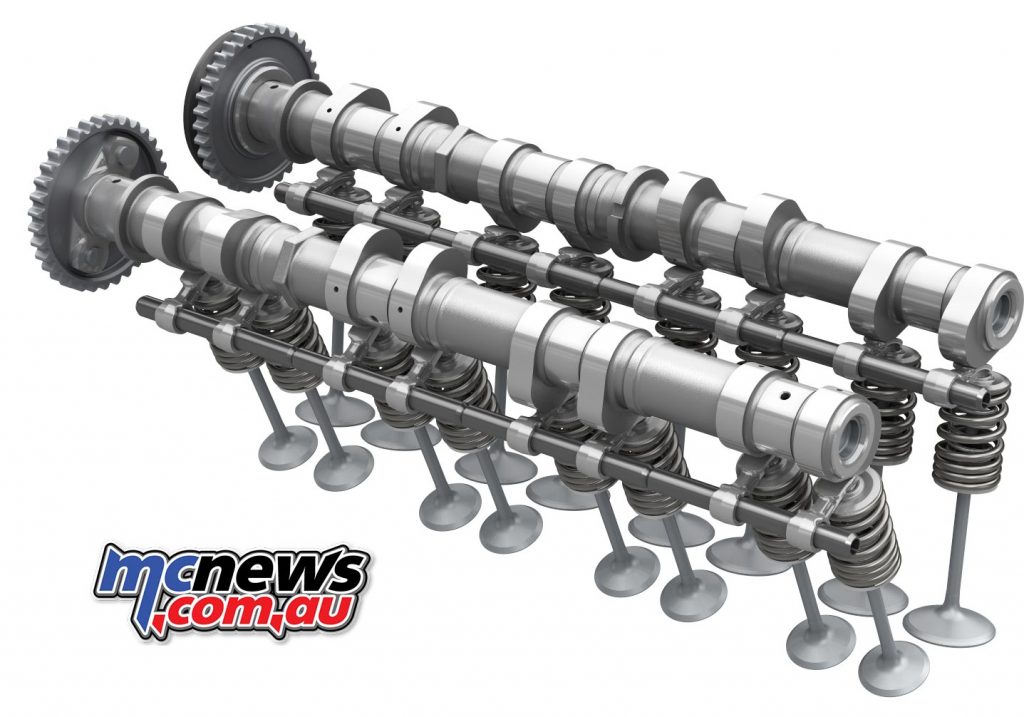

The details started with bore and stroke of 76 mm x 55.1 mm and 999.8cm3 displacement. Followed by a new valve train developed in MotoGP competition, using thinner-wall, hollow camshafts operating lighter, Formula 1-style pivoting finger followers. Each finger follower is 6 grams lighter than a conventional bucket tappet (10 grams vs. 16 grams), and because each follower pivots on a fixed shaft, its moving mass is just 3 grams. The lighter moving mass allows maximum engine rpm and valve lift to be increased while improving valve response and maintaining accurate valve control. Each finger follower inside the GSX-R1000 is designed based on the actual followers used in the GSX-RR MotoGP racebike, including a diamond like coating (DLC) to increase durability.

Finger followers positioned between the valves and the cam lobes are by nature thicker than the top of conventional bucket tappets. To minimise the resulting increase in overall cylinder head height, conventional aluminium valve spring retainers are replaced with thinner, steel valve spring retainers.

The exhaust valves are now made out of titanium instead of steel, are slightly smaller (measuring 24 mm instead of 25 mm) and are lighter (by 8.2 grams each). The reduction in exhaust valve weight contributes to the new engine’s ability to reliably achieve higher rpm, and slightly larger (31.5 mm instead of 30 mm) titanium intake valves help increase high-rpm power. Exploiting the higher engine speed and increasing the high-rpm power without affecting lower and mid-rpm power presented a challenge for the design team. The valve timing required to achieve higher peak power also reduced mid-range and lower-rpm power as a result, this presented a problem to the engineering team.

The solution was the Suzuki Racing Variable Valve Timing (SR-VVT) system developed in MotoGP racing. Unlike complicated systems as used by other manufacturers, the SR-VVT system is simpler, more compact, and lighter. The system is built into the intake cam sprocket and an adjacent guide plate, using 12 steel balls positioned between slanted radial grooves in the intake cam sprocket and straight radial grooves in the guide plate attached directly to the camshaft. As centrifugal force moves the balls outward at high rpm, the offset grooves align, rotating the position of the cam sprocket on the camshaft and retarding intake cam timing, adding significantly to high-rpm power.

The beauty of the SR-VVT system is in its compact simplicity, light weight, reliability and seamless operation. Centrifugal force is constantly produced when the engine is running, and does not consume any power that could be otherwise delivered to the rear wheel. The system is seamless in its transition and produces a significant increase in high-rpm power without sacrificing any low or mid-range output.

The new 4-2-1 thin-wall stainless-steel Suzuki Advanced Exhaust System (S-AES) is also designed to increase high-rpm horsepower without and negative effects on mid-range and lower-rpm power. GSX-R models have long used a servo-operated Suzuki Exhaust Tuning (SET) butterfly valve built into the mid-pipe to help maximise torque throughout the rpm range by optimising back pressure based on engine rpm, throttle position and gear position. But the new GSX-R1000’s exhaust system improves on that concept with the addition of new Suzuki Exhaust Tuning-Alpha (SET-A) butterfly valves.

A header balance tube connects the head pipes for cylinders #1 and #4, and another header balance tube connects the head pipes for cylinders #2 and #3, a design feature that normally increases high-rpm power at the expense of mid-range and lower-rpm power. Suzuki engineers then added a servo-operated SET-A butterfly valve in each header balance tube, which remains closed to enhance mid-range and low-rpm power, then opens at high rpm to add significant top-end power.

Each forged aluminium piston has short skirts and cutaway sides for reduced weight and friction, a DLC-coated wrist pin reduces friction and a carefully shaped piston dome increase compression while also enhancing combustion efficiency. The L-shaped upper compression ring is pushed out against the cylinder wall by combustion pressure, reducing blow-by and improving sealing. The oil control ring features a chrome-nitride coating, which is harder and smoother than conventional chrome plating, reducing friction, increasing durability, and also enhancing sealing.

The pistons are carried by chrome-molybdenum steel connecting rods with a carburised surface treatment to increase strength. The cylinders are built into the upper crankcase casting and are plated with Suzuki’s own race-proven nickel-phosphorus-silicon-carbide bore coating known as SCEM (Suzuki Composite Electrochemical Material), reducing friction and improving heat transfer, durability and ring sealing.

Cut-outs in the sides of the cylinder bores (below the piston stroke) allow air trapped underneath each descending piston to quickly escape to adjacent cylinders where the pistons are rising. The cut-outs minimise internal crankshaft air-pressure resistance to downward piston movement, reducing mechanical power losses, and also contributing to better ring sealing.

The internal passageways were carefully designed to increase the rate at which coolant flows through the cylinder head and dramatically improve heat transfer. A new, higher-capacity radiator equipped with dual fans also helps to make the cooling system more efficient even with a smaller volume of coolant, which also contributes to weight reduction.

The close-ratio six-speed transmission retains the previous model’s internal ratios and vertically staggered shafts to reduce overall engine length. But the gears have been redesigned to handle the power increase. A new Suzuki Clutch Assist System (S-CAS) uses a pressure plate with built-in engagement ramps and cams. The S-CAS design automatically reduces pressure on the plates, (increasing slip and limiting back-torque), during deceleration, downshifts and hard braking on the racetrack. The system also reduces slip by increasing mechanical pressure on the plates during acceleration, allowing the use of lighter clutch springs resulting in an easier pull of the clutch lever.

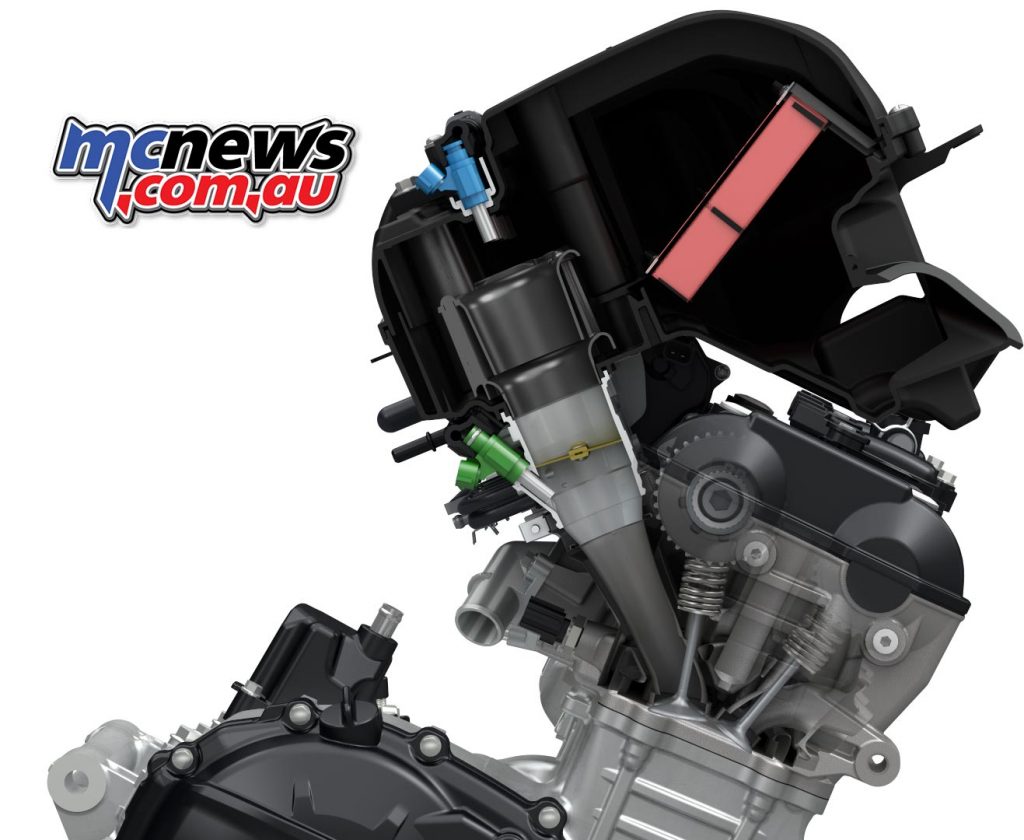

The new throttle bodies are 19 mm shorter, simpler, lighter and more compact than the previous model’s throttle bodies, with a larger bore (46 mm versus 44 mm). Each one has a single butterfly valve controlled by an advanced electronic engine management system, and each cylinder is fed by two ultra-fine-atomisation 10-hole injectors. One injector is mounted at a steep angle in the throttle body itself and operates any time the engine is running. The second showerhead injector—also known as a Top Feed Injector (TFI) -is mounted in the top of the airbox, directly above each throttle body’s intake funnel (or velocity stack), and operates at higher rpm. The TFI showerhead injector delivers additional fuel in an improved spray pattern designed to enhance combustion efficiency, throttle response and top-end power.

The new Suzuki Dual-Stage Intake (S-DSI) system delivers the advantages of variable-length intake funnels (or velocity stacks) without any additional weight or complexity. The S-DSI funnels use a new stacked, dual-stage design, with a longer funnel positioned over a short funnel with a gap in between.

The dual-stage S-DSI funnels are fitted to cylinders #1 and #4, with conventional funnels fitted to cylinders #2 and #3. Shorter conventional funnels are better for high-rpm power and longer conventional funnels are better for low and mid-range power. Thanks to the physics of air flow, S-DSI funnels provide the best of both worlds, acting like a longer funnel at low and mid rpm, and acting like a shorter funnel at higher rpm.

At low and mid rpm, most of the air flows through the longer, upper funnel into the short funnel, increasing low-end and mid-range power. At higher rpm, more air flows around the base of the longer upper funnel and directly into the short lower funnel, increasing top-end power. Using two S-DSI funnels and two conventional funnels helps produce a broader powerband and a seamless transition from low and mid-range into the high-rpm range.

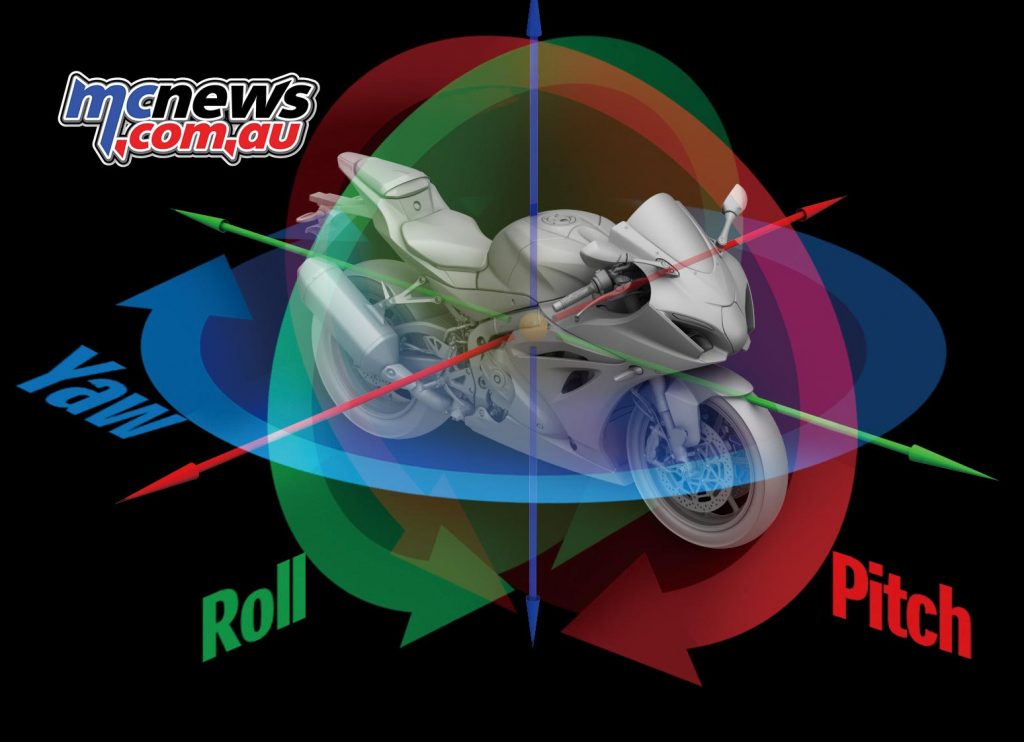

The Continental Inertial Measurement Unit (IMU) based advanced engine management system is operated by a 32-bit dual processor ECM (Electronic Control Module). As the rider turns the throttle, the ECM reads throttle position, crankshaft position and rpm, gear position, front and rear wheel speeds, IMU position, and exhaust oxygen content. The system then either opens or closes the throttle body butterfly valves and increases or reduces the amount of fuel injected to maximise intake charge velocity and produce the most efficient and complete combustion possible. The result is more linear throttle response along with more power, more torque and reduced emissions across the rev range.

The new GSX-R1000’s advanced electronic management system incorporates feedback from the IMU which tracks the motion and position of the motorcycle in 6-directions, along 3-axis, Pitch, Roll and Yaw.

Monitoring these motorcycle motions in real time allows traction, braking and cornering control to be more precise and effective. The GSX-R1000’s IMU-based systems are a product of advanced engineering, developed in MotoGP competition.

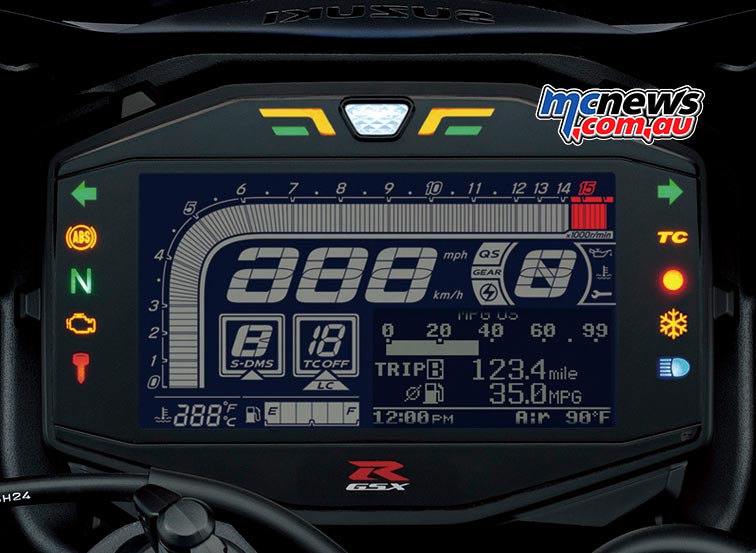

The Suzuki Drive Mode Selector (S-DMS) returns for 2017 although differs in function over the previous design. The switch is located on the left handlebar allowing the rider to easily select one of three different mapping and engine power delivery settings designed to match power delivery to various ambient conditions, such as riding on different racetracks, on tight and twisty roads, in urban settings, in traffic, or on straight and open highways. The rider can change the power mode whilst riding, as long as the throttle is closed. Unlike before, full engine power is available in all three modes with varying levels of low-mid range response between A, B and C modes.

The S-DMS system works in conjunction with the 10-level Motion Track TCS system, offering the rider a wide variety of power delivery and control choices.

Suzuki’s advanced Motion Track TCS allows the rider to select 10 different levels of traction control intervention, depending upon road or racetrack conditions as well as personal preference and experience. The power mode and level of TCS intervention can be changed while riding, as long as the throttle is closed.

The Motion Track TCS continuously monitors front and rear wheel speeds, throttle position, crankshaft position, gear position, and motorcycle motion, and quickly reduces engine power output when a loss of traction is detected or predicted. Power output is controlled by managing ignition timing and throttle valve position.

Motion Track TCS reads sensor input every 4-milliseconds (0.004-second), for precise response and by using input from the IMU (Inertial Measurement Unit), the ECM can calculate the motorcycle’s motion in 6-directions (along 3-axis, Pitch, Roll and Yaw), for more precise traction control.

Mode 1 is the minimum, Mode 10 is the maximum intervention level. Modes 1-4 are designed for racetrack riding; Modes 5-8 are designed for street riding; and Modes 9-10 are designed for slippery road conditions.

Modes 1-4 allow some rear-wheel spin on the racetrack, for the experienced rider who prefers minimal electronic intervention. In Modes 5-8, the Motion Track TCS intervenes earlier than it does in Modes 1-4. When the motorcycle reaches a specific lean angle, the system softens the throttle response and power delivery for easier control using the throttle twist grip. When wheel spin or slide is detected, the system immediately reduces power. Modes 9-10 are designed for slippery road conditions, and the system activates earlier than in other modes.

The instrument panel indicates what Mode has been selected, and a light shows when Motion Track TCS intervention is active.

Low RPM Assist system monitors and automatically adjusts engine rpm when taking off from a stop or riding slowly. The system makes it easier to pull away from a standstill or manoeuvre in heavy traffic or through a crowded car park.

The GSX-R1000R model features a launch control system that makes it easier for a racer to achieve a strong start in racing competition by automatically limiting engine rpm and optimising torque delivery while the rider holds the throttle wide open and concentrates on feeding the clutch lever.

Once launch control is selected using a switch on the right handlebar, the system engages special maps controlling throttle valve opening and ignition timing. The system monitors throttle grip position, throttle valve position, engine rpm, gear position, front and rear wheel speeds.

At the moment of launch, the system is set to hold the engine at the ideal rpm for an effective take-off. Once the clutch lever is released and the clutch engaged, rpm is no longer limited but throttle opening is controlled to keep the engine at the ideal torque for rapid acceleration.

The launch control system not only helps the rider get a good initial launch, but also helps reduce the need to close the throttle prematurely. It does so by working with Motion Track TCS and controlling throttle valve opening and ignition timing while monitoring front and rear wheel speeds. The launch control system automatically disengages when the rider upshifts into third gear or closes the throttle grip.

The GSX-R1000R model also features a new racing-type bi-directional quick shift system, allowing the rider to upshift and downshift without using the clutch or the throttle. The quick shift system allows the rider to upshift smoothly and quickly at full throttle, without the need for closing. The system automatically cuts power delivery just long enough (between 50 and 75 milliseconds, depending upon the sensitivity adjustment) to unload the transmission gear dogs and allow a clean upshift, producing smoother, almost uninterrupted acceleration.

For quicker and smoother downshifts without the need for manually blipping the throttle or using the clutch, the system automatically opens the throttle valves just enough to increase rpm and match engine speed to the next-lower gear ratio.

The quick shift system monitors shift-linkage stroke and shift-cam rotation as well as engine rpm.

The previous generation GSX-R1000 has won many national and world championship races and titles around the world. But professional racers asked for more front-end feel and feedback under racing conditions. Testing revealed that reducing the distance between the front axle and the swingarm pivot could improve the rider’s ability to feel what the front tire was doing during hard cornering on the racetrack.

To find the room to reduce the distance from the front axle to the swingarm pivot, the engineers reduced the forward angle at which the cylinders are inclined from vertical, from 32 degrees to 26 degrees. That made the new engine shorter from the front of the cylinder head to the rear of the crankcases, and provided the room required. Meanwhile, the increase in cylinder bore made the new engine’s cylinder/cylinder-head assembly slightly wider. But by re-routing the oil passageways in the crankcases made the new engine 6.6 mm narrower at its widest point, contributing to better aerodynamics via a smaller frontal projected area.

The GSX-R1000’s all-new chassis is more compact and narrower than the previous model’s chassis. Suzuki engineers designed a new twin-spar aluminium perimeter frame that’s 20mm narrower at its widest point and weighs 10% less. It’s constructed of four sections, welded together. Two main spar sections are built using inner castings and outer stampings to optimise torsional rigidity, and link the cast steering head/front engine hanger section to the cast rear section incorporating upper and lower rear engine mounts and swingarm pivot plates.

The frame is 60mm wider and stronger at the rear engine mounts, reducing vibration. The upper rear shock mount is moved back by 48mm and down by 20mm, making room for a race team to install a modified fuel tank for long-distance events. The new bolt-on rear subframe is now made of square aluminium tubing, reducing weight by 38%.

A new aluminium swingarm is braced on both sides instead of on one, to improve weight and rigidity balance. It’s also 25mm longer from the pivot shaft to the rear-most axle position, improving cornering feel on the racetrack.

The riding position; defined by the relative positioning of the footpegs, the seat and the handlebars is unchanged. But it’s now easier for the rider to tuck in due to the top of the fuel tank being 21mm lower than before, there’s also more room for a helmet chin bar when the rider is fully tucked in. The fuel tank is narrower and sleeker, making it easier for the rider to move from side to side and quickly change direction. The tank is also easier for the rider to grip with their knees while entering hard-braking corners on the racetrack, and the shape of the tank flows seamlessly into the seat and tail section.

The standard GSX-R1000 model’s Showa BPF (Big Piston Front) forks well out-perform the suspension fitted to the standard models sold by market competitors. The design eliminates the internal cartridge assembly used in conventional forks and instead uses a larger piston riding against the inside wall of the inner fork tube itself. The design responds well to small bumps with more effective compression damping, especially during hard braking on the racetrack. BPF forks feature adjustable rebound damping, compression damping and spring preload.

The GSX-R1000’s Showa rear shock works with a progressive linkage and rebound damping and both high-speed and low-speed compression damping are adjustable, as is spring preload and rear ride height.

The GSX-R1000R model goes a step further with the latest Showa BFF (Balance Free Front) forks and BFR lite (Balance Free Rear lite) rear shock, developed for racing and now adapted to a mass production motorcycle. Both improve cornering traction by delivering smoother, more controlled travel and damping control over pavement imperfections. The BFF system equalises (or balances) oil pressure above and below the solid internal piston as it moves, pushing oil out of the fork leg (or shock) and through damping circuits that run to the other side of the piston, where its drawn back into the fork leg (or shock). The external compression and rebound damping circuits are more precise than valve stacks fitted above and below the piston in other types of forks and shocks, and damping control is “set free” (or isolated) from the influence of unequal pressure. It’s a difference that can be felt on the racetrack, with riders reporting better feel and drive grip that allowed them to initiate their drive sooner and accelerate out of corners harder. As is the case with the standard model, the GSX-R1000R model’s BFR lite shock works with a progressive linkage. Naturally the BFF forks and the BFR lite shock are fully adjustable.

Both models come equipped with an automatic steering damper. The ECM monitors wheel speed and uses a solenoid to move a tapered needle in an oil passageway to adjust oil flow, increasing damping force at higher speeds and reducing damping force for lighter steering at lower speeds.

New Brembo stainless steel brake discs are 10 mm larger in diameter, measuring at 320mm. Each disc features a new hybrid mounting system using a 50/50 combination of 5 conventional spring loaded floating pin mounts and 5 Brembo T-drive floating mounts.

The Brembo T-drive floating mounts are lighter yet have more contact area between the disc and inner carrier, requiring fewer mounts (10) than conventional mounts alone (12), minimising the weight gain from the larger discs.

T-drive mounts can also produce an audible rattle in certain conditions. Conventional spring-loaded pin mounts are slightly heavier and produce a smaller contact area, but are quieter. Using a combination of T-drive and pin mounts reduces rattle as well as requiring fewer mounting points.

The GSX-R1000’s Brembo radial-mount, monoblock front brake calipers each feature four 32mm pistons and work with a radial-pump, 19mm master cylinder. The rear brake system uses a single-piston caliper and a 220mm disc. The front brake lever end is slotted to reduce the possibility brake drag at high speed.

Both Australian GSX-R1000 models are equipped with the new Motion Track Brake System, which works in conjunction with the IMU (Inertial Measurement Unit). Using IMU input, the Motion Track Brake System reduces rear-wheel lift during very hard braking on the racetrack, and is especially effective on downhill braking sections of a track. On the GSX-R1000R, the system also optimises brake pressure when the motorcycle is leaning.

New lightweight, 6-spoke cast aluminium wheels contribute to nimble handling performance and sporty appearance and are fitted with Bridgestone’s Battlax Racing Street RS10 radial tyres. A larger 190/55ZR17M/C (75W) rear tyre replaces the previous 190/50ZR17M/C (73W) and is designed to handle to increased horsepower and torque output.

The 2017 GSX-R1000 sports MotoGP-inspired, sleeker and more aerodynamic bodywork designed to improve handling and overall top-speed on the racetrack.

The front fairing is 13mm narrower, and the reshaped fairing ears are closer to the handlebars resulting in increased air flow around the rider’s hands and arms. The lower leading edge of the fairing nose directs air into new Suzuki Ram-Air Direct (SRAD) intake ducts, which have a smoother internal shape that increases the flow of pressurised air into the airbox. The fairing radiator cowl projects forward on each side, directing more cooling air into the radiator itself.

The new front fender shape increases down force, smooths out the flow of cooling air into the radiator and increases the air reaching the front brake calipers.

The bodywork has a more connected flow line from the fairing nose to the tail section. It has a smaller frontal projected area and smoother wind-tunnel-developed lines, reducing the coefficient of drag and also reducing lift at racetrack speeds. It’s lighter, producing less moment of inertia and less leverage on the centre of gravity.

An all-new LED headlight is more compact than a halogen unit and also produces excellent lighting. Installed in the nose of the fairing, the LED headlight is narrower and shorter, contributing to the new GSX-R’s improved aerodynamics. The low-beam and high-beam elements are stacked, with the low beam positioned above the high beam. New LED daytime running lights are located above the SRAD intakes on each side of the GSX-R1000R’s headlight.

Both model variants feature LED elements for the vertical taillight and brake light assembly, as well as for the registration plate light. The LED registration plate light is about half the size and significantly lighter than a conventional bulb, yet produces more light and is better at resisting vibration, allowing the rear fender assembly to also be lighter. Both GSX-R1000 models have LED indicators.

The new GSX-R1000 features full LCD instrumentation. The dash is brighter and easier to read, and incorporates S-DMS mode and Motion Track TCS level indicators as well as a fuel gauge and readouts showing instantaneous or average fuel consumption, ambient temperature, freeze warning and service reminders. Other features include a relocated, more visible shift light and the usual speedometer, tachometer, odometer, tripmeter, clock, lap time, and water temperature displays. Other indicators include neutral, high beam, turn signal, and ABS operation. The gear position indicator is linked to a new, more accurate magnetic sensor. The GSX-R1000R model also comes with a lighter, more compact battery.

The all-new GSX-R1000 and GSX-R1000R are expected to arrive in Australia during the second quarter of 2017 with final specifications, colours and pricing being confirmed closer to launch.