Could carbon-fibre swingarms eventually go mainstream?

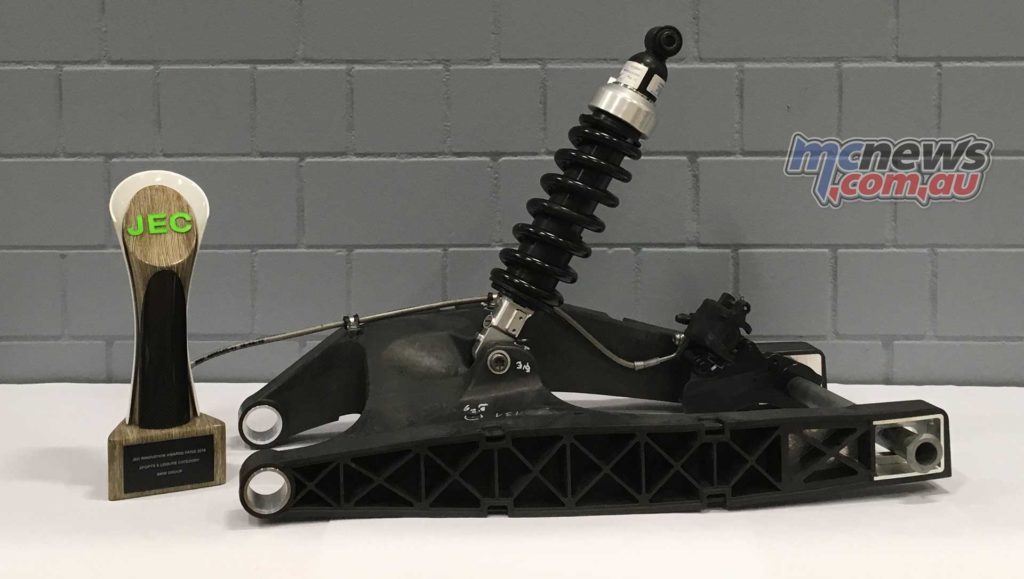

BMW Motorrad has been presented with the 2018 JEC Innovation Award in the Leisure & Sports category for the development and manufacture of a rear swinging arm made of carbon fibre.

Established in 1996, the JEC Group is the world’s leading specialist organisation for the development, manufacture and processing of composite materials.

BMW uses lightweight construction across both their car and motorcycle groups. The latest example from BMW Motorrad was the HP4 RACE, where the entire main frame was made of carbon fibre reinforced plastic produced by means of an industrial RTM process.

In 2017 the carbon fibre frame of the HP4 RACE opened a whole new chapter in motorcycle chassis construction, combining optimum technical qualities, uniform manufacturing quality and cost efficiency for the first time.

BMW Motorrad has now taken a further step towards consistent lightweight construction under the project MAI hiras+handle. This project was sponsored by the German Federal Ministry of Education and Research as part of the leading-edge cluster MAI Carbon. The aim of this cooperative venture bringing together seven partners from industry and research was to develop a process that enabled the cost-effective volume-production use of carbon fibre composite materials (CFP) in structural components subject to high levels of continuous stress. In the case of this particular part, it was also possible to establish a cost-efficient manufacturing process suitable for the large-scale production of injection mould components made of carbon fibre reinforced plastic with CFP tape reinforcements using thermoplastic material.

Project manager Elmar Jäger explains the development of the concept

“We opted for chassis components under continuous load since the requirements involved are especially demanding. Our production technique uses CFP in the form of high-strength endless fibres where this is required by the stress pattern, while an injection mould part with short CFP recycling fibres is used where the stress levels are not as high. In this way, we developed a cost-efficient design that can be scaled according to requirements by inserting endless fibres with varying levels of strength in the same tool. These were the points that impressed the international jury. The insights we gained from this motorcycle component are equally valuable from the point of view of car development and can be applied accordingly.”

Joachim Starke explains the new production process

“In addition to achieving weight benefits and cutting costs significantly, we also managed to develop a technology that allows precise configuration of component properties by using a variety of composite and metal inserts. This scalability means that a single tool can be used to produce a wide range of different components at cycle times of less than a minute. The maximum strength can be adjusted by means of additional CFP panels which can be thermoplastically joined. The project also involved successful testing with welding robots. All this impacts significantly on cost efficiency (component costs) as well as part properties (strength and stiffness).”