Claudio De Martino

Chief Engineer of the 2019 BMW S 1000 RR

With Steve Martin

Claudio De Martino reminds me Patrick Swayze in the movie ghost, where he is moulding clay adding passion and love in the background, making sure all is good. As chief engineer he’s definitely one of the ideas men behind the S 1000 RR project and like everyone involved he knows how to punt one of the new S 1000 RR machines pretty damn fast. We caught up with him at the Estoril launch of the new 2019 model for a chat.

Claudio De Martino Interview

Steve Martin: Thanks Claudio for taking the time to talk to us, first of all how long did it take to develop this bike?

Claudio – “So, we have different phases, and the complete phase for developing is 46 months, but the previous phase is to define for example the configuration of the engine, which way the counter-shaft rotates, how many cylinders and so on. This is before you define it, and then 46 months from that point to production.”

Steve: When you were looking at this bike, basically the engine is a clean slate, a clean sheet, was there any time that you guys considered making it a big bang style motor.

Claudio – “Yes, we considered, but we are BMW and we always have the highest peak power, and with the big bang it’s not possible to do peak power, so we decided to stay on the screamer.”

Steve: Why not a counter rotating crank then?

Claudio – “Because we avoid additional excess, this part also has weight and will cost some horsepower, and so we decided to have maximum horsepower, and the result is only possible with a screaming four, and normal rotating crankshaft.”

Steve: When you sat down what was the target going to be? How much faster did it need to be than the 2018 bike?

Claudio – “It’s important to have big and strong goals which everyone can keep in mind, and we said of course our bike the 2017 and 2018 was a benchmark, and we said one second faster on the lap, easier to ride, feeling comfortable. But one second was the major goal and every decision we had to make we asked ourselves, is it supporting our goal, makes us faster, makes us lighter. So, a major goal was going that one second faster.

“How did we reach? We checked every part, somebody said OK, to be one second faster we had to be more than 10kg lighter, if we have to be 10kg lighter to reach our goal, what do we have to change, and at least it was everything.”

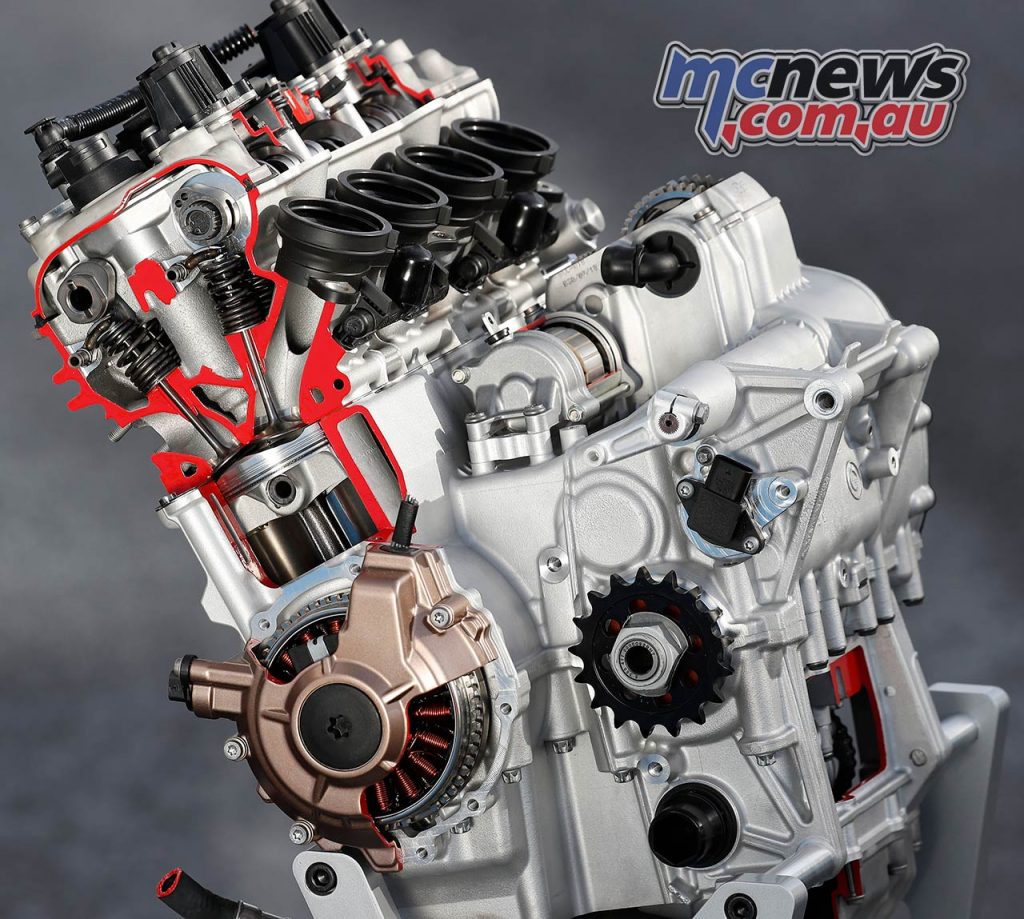

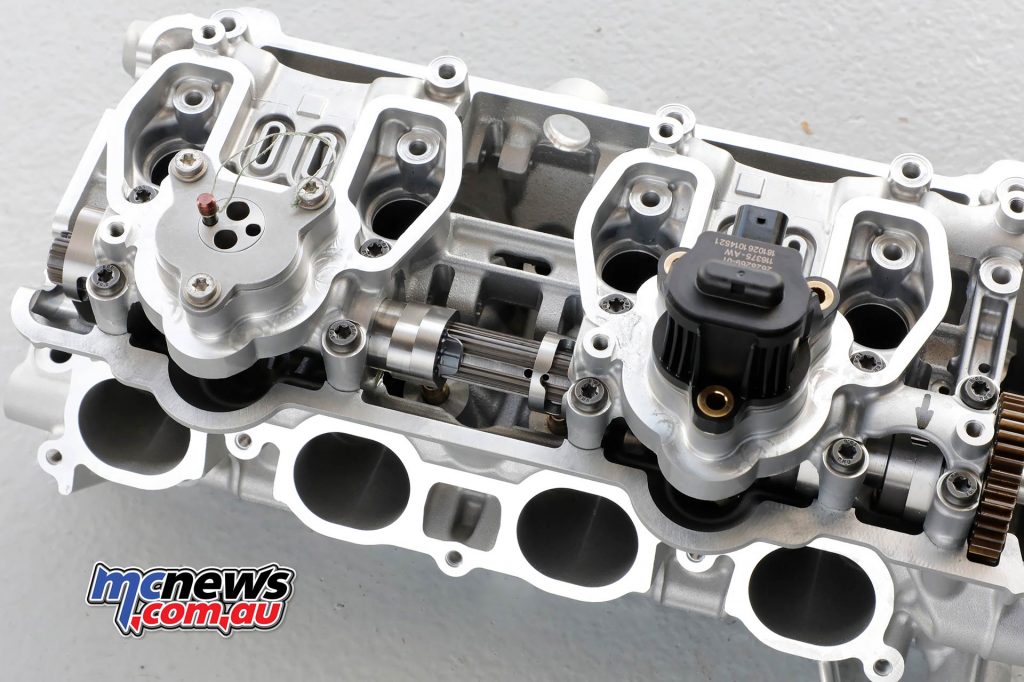

Steve: There’s a lot of new technology put into this bike, especially with the valve train.

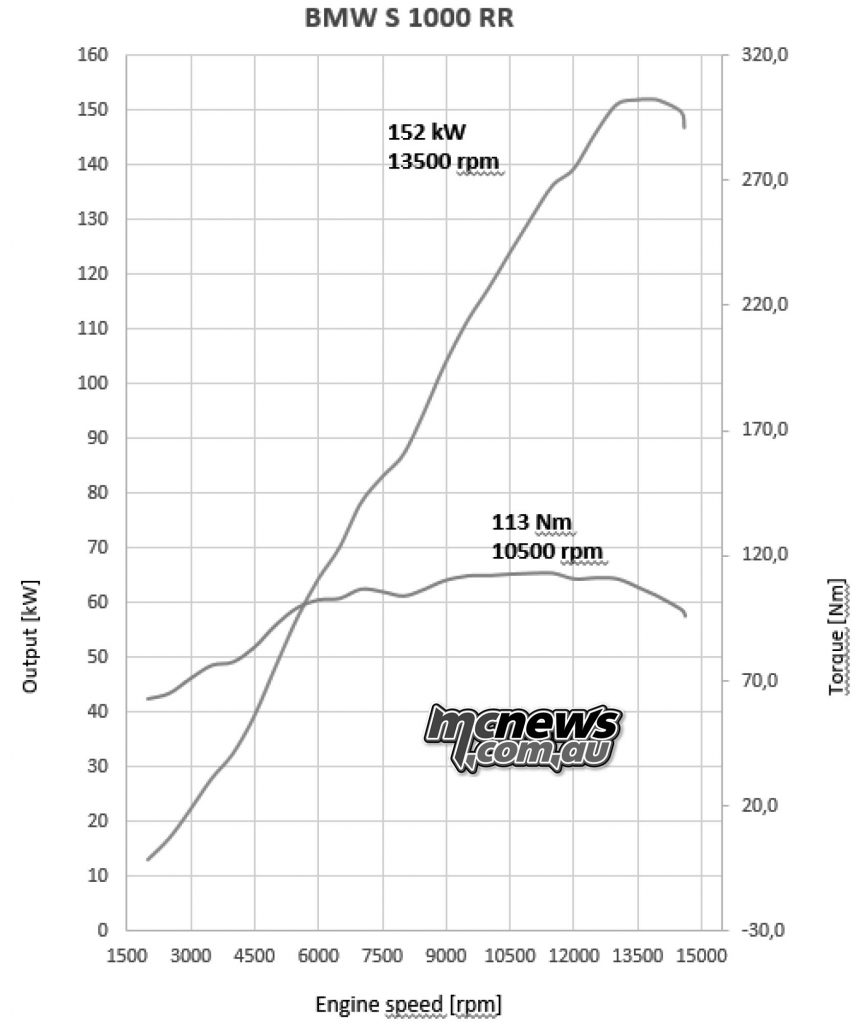

Claudio – “The valve train is also helping us to make the compromise from more horsepower at high revs and of course a good torque curve, in mid-range and at low rpm. So sometimes it’s easy to have more peak power, but you lose a lot of torque and we have now this combination and for me, I liked always to explain for the rider its necessary to know what he gets when he opens the throttle.

“This is the same if you open at 5500rpm, 7000, 9000, 11000, you always get more than 100Nm [of torque] and it’s easy for you to control. You don’t have any area where there’s a big jump of the torque curve and you get a big surprise or trouble.”

Steve: You’ve changed a lot of different partners this year, gone away from Brembo brakes, which you’ve had in the past, you’ve got Hayes brakes on the front now, and you’ve also got the Marzocchi suspension – you’ve gone away from the Sachs, what was the reasoning behind that?

Claudio – “At the beginning we wrote down on a letter, what we’d like to have for the next model, so this was a new spec for each part, we went to different suppliers asked them can you deliver this, they said yes OK we can do it.

“Then there was a big shoot out where we compared the parts, with experienced riders. They didn’t know what was mounted, they only thought about the feeling, and at least we took the one who supported our goals the most. In this case with choosing the suppliers we’re quite happy with this.”

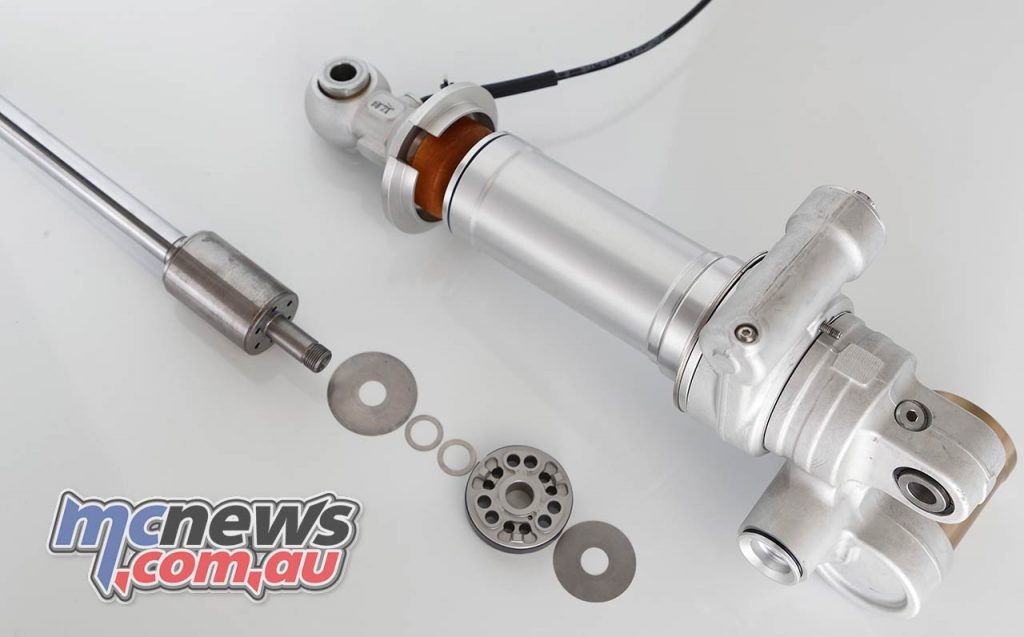

Steve: I guess the big difference in this suspension, compared to the old electronic suspension, the old one had car valves in it, but this has a conventional shim stack in there. How does that work and why the change?

Claudio – “Exactly, the big change is the car valve was the first generation, we put a lot of currency into the car valve to find out function, but when we reviewed the system, we said what does a racer need? He needs good feeling for the bike, and the conventional parts, they give very good feel, or a known feeling, so we thought to combine these two technologies, and at least we have separated conventional part and an additional electronic part.

“On the race track, more than 90 per cent you work on the conventional part, and that’s what you feel, and the confidence for the bike. On the road, with a passenger, there the electronics increase. So, on the race track it’s nearly conventional. And of course, every specialist, can open this system, can adapt it to your weight, your riding style and it will be fine for the customer.”

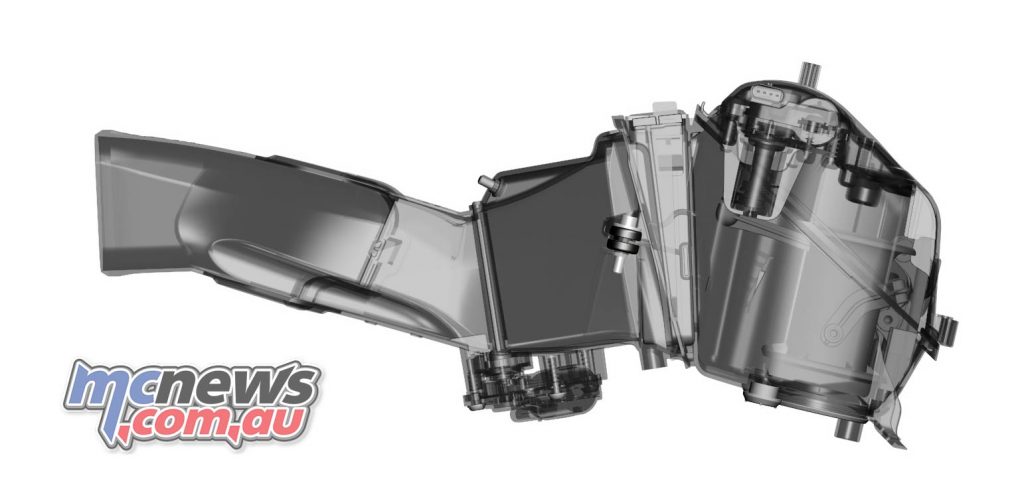

Steve: I guess that’s the other thing about this bike, you don’t need special tools to work on it. You can adjust everything from the dash. So, the TFT dash must have taken a long time to sort that out.

Claudio – “Yea it’s new technology and it offers a lot of possibilities, you have to have good heads who can write down what must be the requirements, and after all we have a lot of experience with these systems now, so it offers a wide range for personal adjustment and this is in combination with the dash and with the menu, it’s outstanding.”

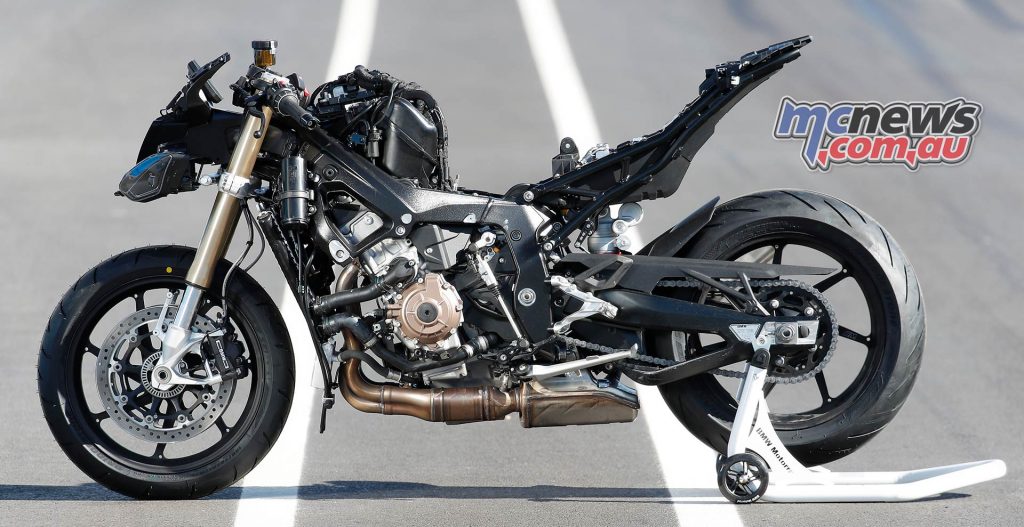

Steve: Let’s talk about the frame, when I was involved developing the old frame, we had lots of special frames before the current unit was chosen, what was the process this time around.

Claudio – “So, the frame is also a result of reviewing the old bike, everybody knows the shape with the stable connection between steering head and swing pivot. We put some material in the engine, but it’s also four kilogram lighter – the engine, so the engine took more rigidity and more stability.

“The frame when you look the shape, you have the shortest way the direct connection to the mounting points in the front, and in the rear, we call it a doughnut, it’s a very stable, one part hollow casted, which is also fixed four times to the engine, in between these areas. They take also some work for the flex, but we can define the flex by the thickness of the material.

“So, there was some areas to play, also there was some simulation testing and then we defined the shape, the thickness, and it also offers us the possibility to move the knees very narrow. With the old shape of the frame, it was not possible to have this feeling like a V4, we liked to have it like one of our competitors and we would push the knees inside, inside. This frame will help us to reach that.”

Steve: This bike is obviously made to win WSBK and be competitive in near standard form for the track day competitors, what about the road guys out there? Some of your competitors are bringing out 1100cc versions, are you planning anything like that, or have you thought about it how this bike can compete with an 1100cc.

Claudio – We have BMW shift cam, it’s our secret weapon.

Steve: Thanks Claudio.