2016 Honda CRF250R

The CRF250R gets a substantial top-end power boost from a new HRC-developed cylinder head, piston and con-rod, with stronger bottom-end torque and no loss of mid-range performance.

Showa’s SFF-TAC-Air forks receive upgrades to reduce friction and improve response and damping; Showa rear shock has new settings to match.

There’s no tighter competition than the elbow-to-elbow MX2 class, at amateur or professional level. And Honda’s CRF250R has long been a potent weapon to take into battle thanks to its fluid power delivery and honed chassis that balances lightning-fast agility with sure-footed stability. It shares the same aluminium beam frame and mass-centralised design philosophy as the CRF450R and turns as well airborne as it does on the ground.

The 15YM CRF250R received 49mm Showa Separate Front with Triple Air Chamber (SFF-TAC-Air) fork, to fully exploit the chassis’ ability. It also got the same Engine Mode Select Button (EMSB) as its larger-capacity sibling, giving a choice of 3 riding modes – standard, smooth or aggressive – for the rider to select from the right side of the handlebar.

But nobody rests when it comes to MX2 development and the smallest improvements can make the biggest differences when combined. For 2016 Honda has dialled in an array of upgrades to the CRF250R’s engine and suspension, driven entirely by what Team HRC learn racing week in week out against the world’s best in MXGP.

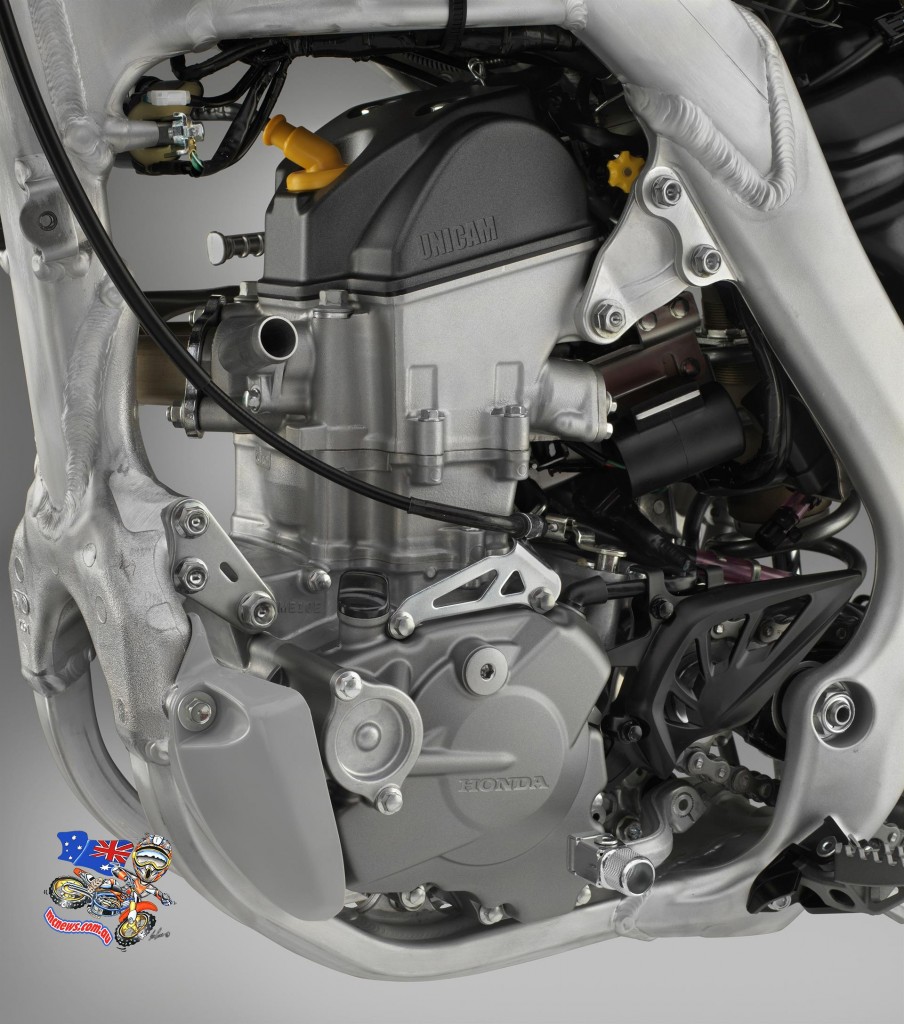

The main focus of the 2016YM CRF250R revolves around a completely revised cylinder head, piston and con-rod. And the result is power – and a good deal more of it up top, with no loss of bottom end response, throttle feel or delivery. In fact low-rpm torque is improved, as is high-rpm over-rev. The exhaust downpipe now features a resonator chamber and the twin rear mufflers redesigned internals. The airbox, too has been revised to improve air flow.

Showa’s SFF-TAC-Air forks receive a host of internal changes plus an extra 5mm length in the top tubes to enhance traction, suspension reaction, rider feel and adjustability. The rear shock setting is also adjusted to match. Other changes include a reduction in final drive chain roller diameter and improved mud-clearing ability for the footpegs.

The CRF250R’s 249cc four-valve Unicam engine retains a bore and stroke of 76.8mm x 53.8mm. Peak power is now 29.4kW @ 11,500rpm (from 28kW @ 11,000rpm) with peak torque of 27.1Nm @ 9,000rpm (from 26.5Nm @ 8,500rpm).

The new engine is smoother and stronger off the bottom, maintains its mid-range punch and as revs rise makes not only more power and torque, holds onto it at higher rpm and for noticeably longer – useful for stringing sections or corners together without changing gear.

The increase in peak power and torque – with zero sacrifice anywhere else in the rev-range – is due to extensive HRC development of the cylinder head. It starts, however with a new, lighter piston which also delivers a compression ratio of 13.8:1 (up from 13.5:1). It’s matched to a lighter con-rod, with revised shape, that contributes to the power gain.

On the intake side the airbox features an added air intake duct plus revised inner duct length and insulator. Both the intake and exhaust ports are redesigned to HRC-specification and the 25mm diameter exhaust valves are now titanium (rather than steel) matching the 30.5mm intake valves. A brand new camshaft profile operates redesigned valve lifters; both intake and exhaust valve lift has been increased. The inlet valve spring material is also new. The PGM-FI Dual Fuel Injection – with 46mm throttle body – features new settings to match the engine’s new free-flowing head.

The exhaust employs a resonator tucked away between the pipe and engine which helps improve drivability. Both mufflers use new connector tubes and inner pipe punch pattern, plus larger tail-end diameters. The left hand radiator is larger to cope with extra heat generated by the power boost and the gearbox now has a bearing-type shift drum stopper for improved feel at the gear lever. The chain roller diameter has decreased, from 38mm to 34mm.

Honda’s EMSB makes an already very usable engine even more adaptable. This is a plus for the club racer in particular; rather than set up during the week and hope for matching conditions at the weekend, the rider just has to stop with the engine at idle and press and hold the button for just under a second to select the next map in sequence.

A highly visible LED built into the lightweight button signals the map in use with a quick press and number of subsequent flashes. If a new map is selected the choice is also confirmed to the rider.

Mode 1 uses the standard combination of ignition and fuelling maps to present a balanced power and torque delivery. Mode 2 is designed for use in slippery, muddy conditions and is all about throttle control, giving easy-to-manage feel that hunts out every last scrap of traction. Mode 3 hits hard with aggressive and responsive top-end power to drive through soft sand. Mode 2 and 3 can be further tailored via the existing HRC mapping hardware and software.

The 49mm SFF-TAC-Air forks were developed specifically for the CRF250R by Showa to unlock the frame’s performance potential and save over 1kg in weight compared to conventional forks. The fully adjustable right fork leg controls both compression and rebound damping force while the left fork leg compresses air using a damper-less structure. This distribution achieves a controlled right/left balance.

Three chambers are used by the left fork leg to manage suspension reaction (or effective ‘spring’ rate). The Balance chamber operates from the off and at low speed; the Inner chamber is responsible for the mid-range stroke and the Outer Cylinder chamber is used as the forks near their bump stops.

Both fork legs employ the same stroke and internal dimensions as employed previously but have received extensive development – the two main goals to reduce friction through short strokes, improving suspension reaction speed and also to increase reaction force at mid-stroke, boosting control during pre-jumping and landing. Both rebound and compression damping characteristics have been increased to suit the new set-up.

The top tubes are 5mm longer above the top yoke, and to reduce internal friction – by approx. 25% – the construction, shape and number of inner air seals has been finely adjusted. 80kPa air pressure has been added to the Outer Cylinder chamber; previously this contained 0kPa. It also receives a dedicated air valve for adjustment. Both the Inner and Balance chambers now use 1075kPa, from 1200kPa/1125kPa. The damping adjustment range increases from 4 click/rotate to 8 click/rotate.

The compact Showa shock mounts low within the frame spars. To balance the changes up front – and maximise rear-wheel traction – it now uses a heavier spring rate in the early part of its stroke. Rebound damping remains unchanged but compression damping increases (compared to 15YM) from mid-stroke on as the piston speed rises.

Fully adjustable, the rear shock features 17-position rebound adjustment; compression damping is separated into 13-position (low-speed) and 3.5 turns (high speed). Honda’s Pro-Link rear suspension linkage operates CRF250R-specific ratios and allows 31.7cm of travel. The aluminum swingarm features deep beam height in the front and centre sections, minimising rut deflection and improving rear tyre traction on corner exit.

The CRF250R’s aluminium twin-beam frame – in its sixth generation – was designed from the outset around the use of air forks and with mass centralisation at its core. It is unchanged for 2016. Rake is set at 27.23, with 117mm trail and wheelbase of 1,489mm. All-up kerb weight is 105.6kg. A CRF250R-specific lower cradle houses the engine.

The 16YM CRF250R’s bodywork is also unchanged and maintains Honda’s man maximum/machine minimum ethos that’s built around the need for a rider to move freely; efficient riding ergonomics are at the heart of the CRF250R shape. The radiator shrouds, side covers, lightweight seat and fuel tank offer a slim, smooth and continuous transition allowing the rider huge freedom and flexibility of movement. Detailed improvements to the footpegs and their mounts make it much harder for close-packed mud to jam the footpeg in an ‘up’ position.

A 260mm wave-pattern front disc delivers superb heat dissipation, power and feel from the two-piston brake caliper working it; a matching 240mm wave-pattern disc and single-piston caliper is at the rear. Lightweight aluminium rims wear Dunlop MX52F/MX52 80/100-21 front and 100/90-19 rear tyres.

2015 Honda CRF250 R Technical Specifications

ENGINE | |

Type | Liquid-cooled 4-stroke single cylinder uni-cam |

Displacement | 249cc |

Bore ´ Stroke | 76.8mm x 53.8mm |

Compression Ratio | 13.8 : 1 |

Max. Power Output | 29.4kW @ 11,500rpm |

Max. Torque | 27.1Nm @ 9,000rpm |

Oil Capacity | Engine oil 0.85 litres / Transmission oil 0.75 litres |

FUEL SYSTEM | |

Carburation | Fuel injection |

Fuel Tank Capacity | 6.3 litres |

ELECTRICAL SYSTEM | |

Ignition | Full transistor |

Starter | Kick |

DRIVETRAIN | |

Clutch Type | Wet multiplate |

Transmission Type | Constant mesh |

Final Drive | Chain |

FRAME | |

Type | Aluminium twin tube |

CHASSIS | |

Dimensions (L´W´H) | 2,181mm x 827mm x 1,271mm |

Wheelbase | 1,489mm |

Caster Angle | 27° 23′ |

Trail | 117mm |

Seat Height | 951mm |

Ground Clearance | 322mm |

Kerb Weight | 105.6kg |

SUSPENSION | |

Type Front | Showa 49mm inverted SFF-TAC air fork (310mm stroke) |

Type Rear | Showa monoshock using Honda Pro-Link system (317.6mm stroke, 133mm axle travel) |

WHEELS | |

Type Front | Aluminium spoke |

Type Rear | Aluminium spoke |

Tyres Front | 80/100-21 Dunlop MX52F |

Tyres Rear | 100/90-19 Dunlop MX52 |

BRAKES | |

Front | 260mm hydraulic wave disc |

Rear | 240mm hydraulic wave disc |

All specifications are provisional and subject to change without notice.