Ducati Panigale V4 motorcycle to be unveiled November 5

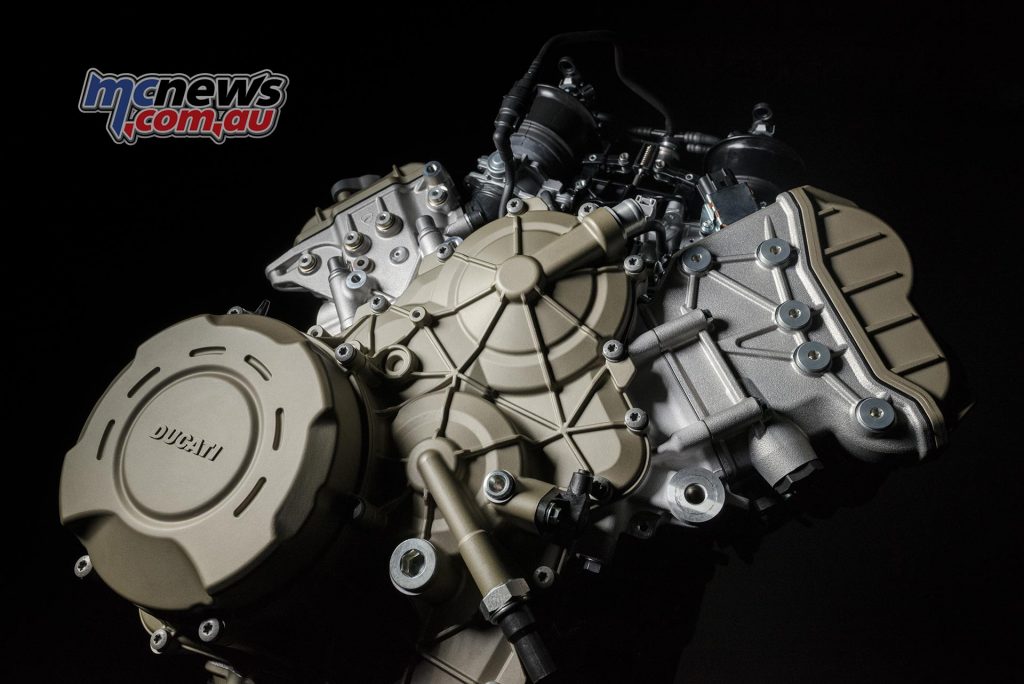

90-Degree V-4 counter-rotating crankshaft – 1103cc

R version with a displacement of less than 1000 cc is at advanced development stage

Road motorcycle due in 2018 while sub 1000cc race version due in 2019

A new direction for Ducati has been unveiled at Misano this evening when the Bologna based manufacturer pulled the covers off their new Ducati Desmosedici Stradale engine that will power the next generation of premium level Ducati sportsbike motorcycles.

[youtube id=”Gsn7kmHngzg” width=”100%” height=”400″]

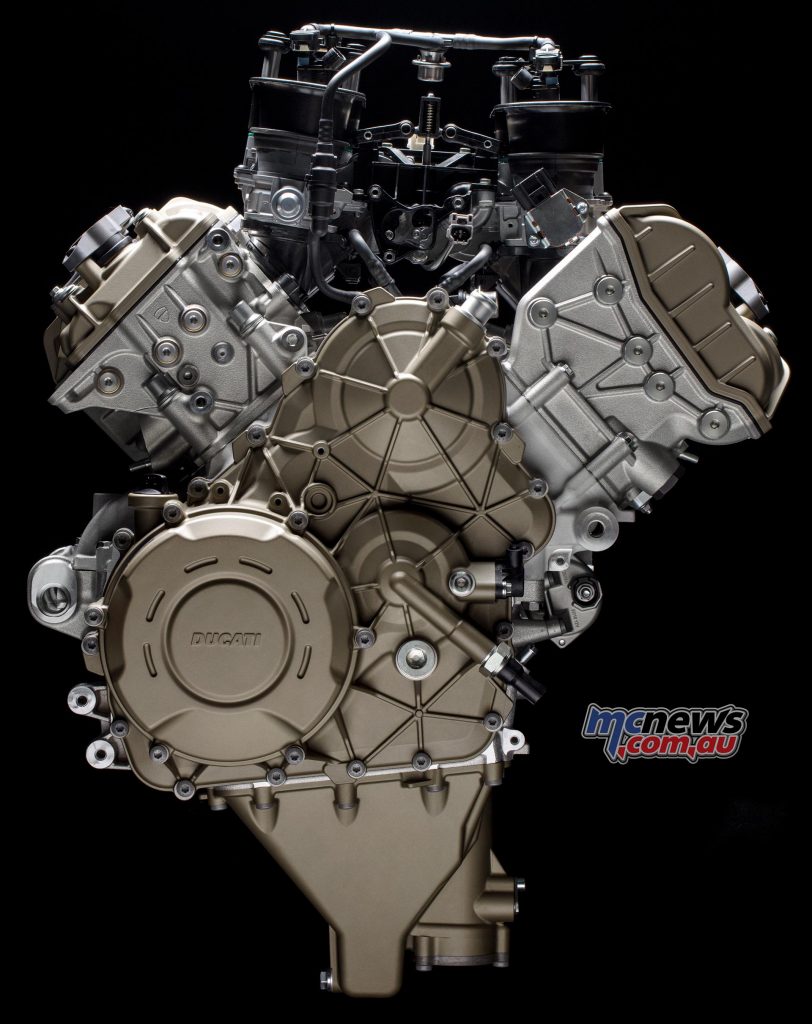

- 1,103 cc 4-cylinder 90-degree V engine

- Bore x stroke 81 x 53.5 mm

- Compression ratio 14:1

- Maximum power exceeds 155 kW (210 hp) at 13,000 rpm

- Maximum torque exceeds 120 Nm (12.2 kgm) from 8,750 to 12,250 rpm

- Euro 4 emissions

- Desmodromic part chain, part gear [timing with dual overhead camshaft, 4 valves per cylinder

- Counter-rotating crankshaft with crank pins offset at 70°

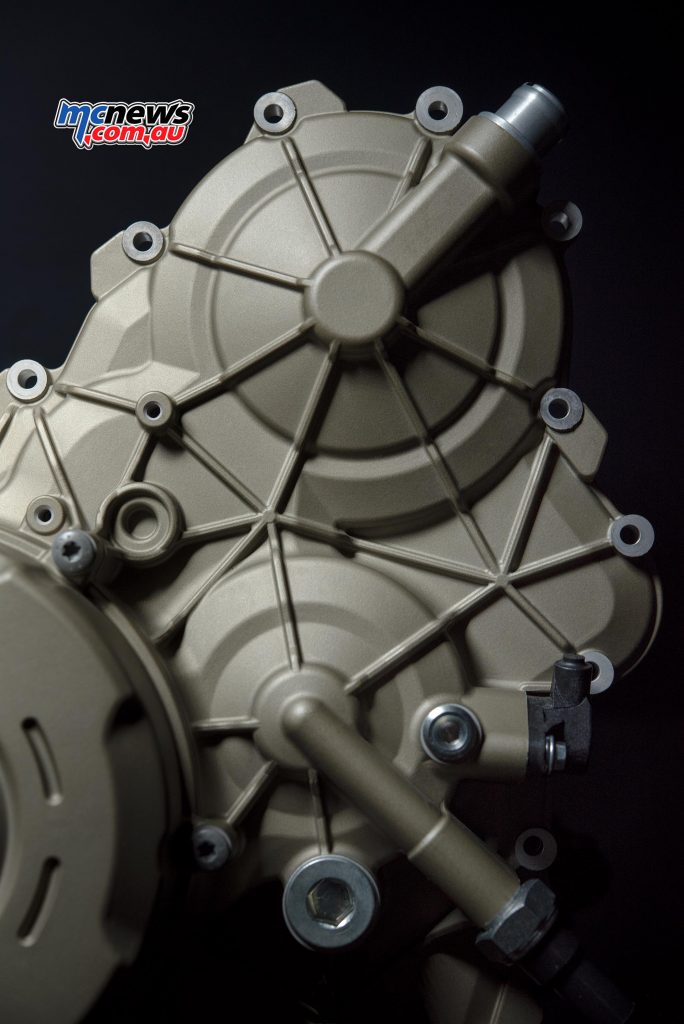

- Wet multiplate anti-patter servo clutch

- Semi-dry sump lubrication with four oil pumps: 1 delivery and 3 return

- Fuelling with four oval throttle bodies (52 mm diameter equivalent) and variable-height intake horns

- 6-speed gearbox with DQS up/down system

- 24,000 km “Desmo Service” maintenance interval (15,000 miles)

Not since the release of the limited edition Desmosedici RR in 2007 has Ducati made a four-cylinder machine for the road, but that is all set to change in 2018 with the birth of the Desmosedici Stradale: the new Ducati V4 engine.

This new 90-degree V-Four engine is expected to power a new generation of Ducati motorcycles at the premium end of the market.

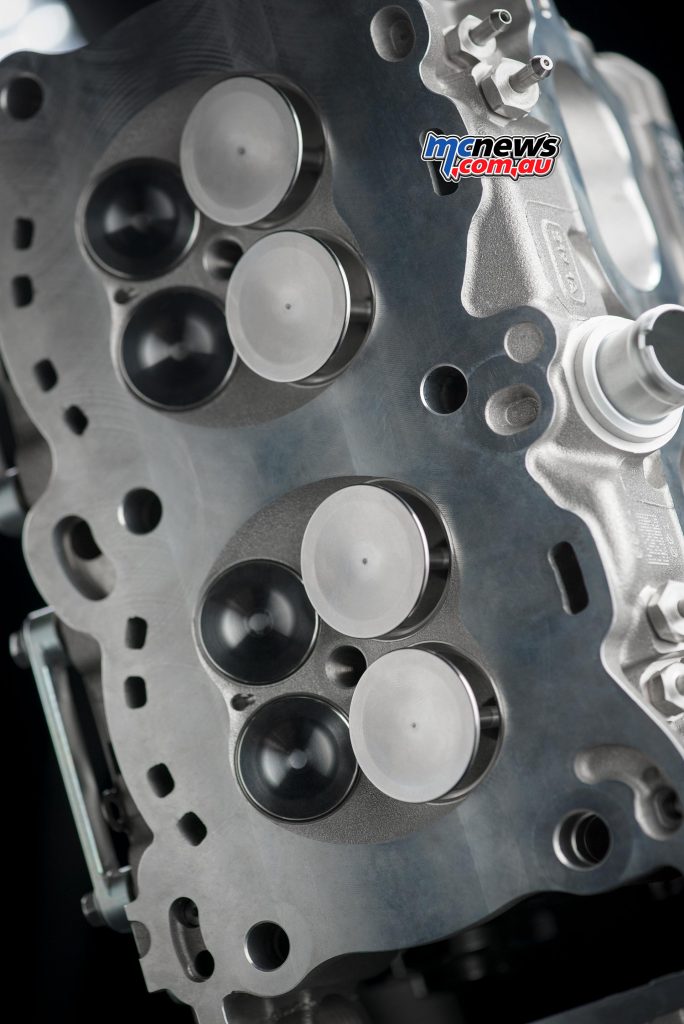

The starting point for the Desmosedici Stradale design was the heart of the V4 MotoGP engine – its cylinder heads. With the same dimensions and geometry as the Desmosedici GP, the Desmosedici Stradale offers the same outstanding fluid dynamics.

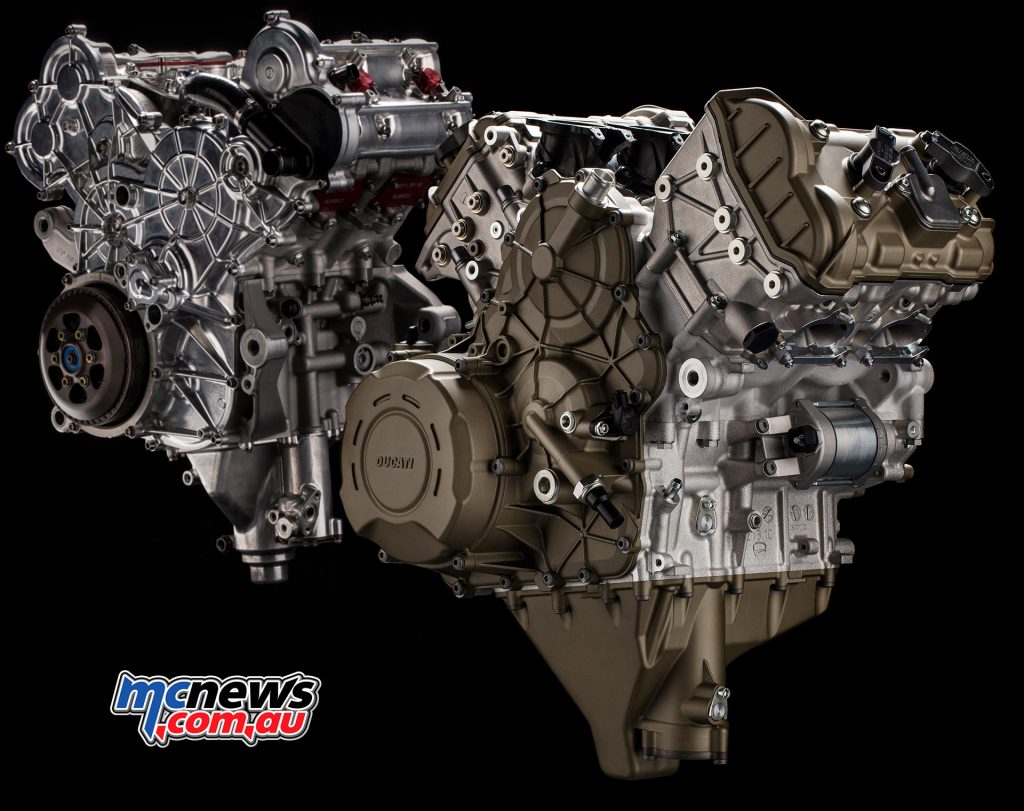

It also has the same engine configuration: 90° V4, rotated rearward by 42°. This solution makes the new Ducati engine extremely compact, allowing centralisation of mass and perfect integration with the vehicle.

As on Ducati competition bikes, the crankshaft is the counter-rotating type. This reduces the gyroscopic effect exerted by the wheels and makes the bike faster and more agile when changing direction. It also reduces the wheelie effect when accelerating and rear wheel lift when braking. The crank pins have a 70° offset, giving rise to a “Twin Pulse” firing sequence that, in addition to producing a unique signature sound, delivers easy-to-handle power and excellent out-of-the-corner traction.

While the Desmosedici Stradale engine is undoubtedly suited to the track, it has also been designed to respond to the needs of the road rider. For example, to maximise mid-range torque – essential for a satisfying road experience – and ensure punchy torque and power at lower revs, the engine has a slightly larger displacement than its MotoGP counterpart (1103cc, to be precise).

Power output fromthe Euro 4 compliant engine configuration exceeds 155 kW (210 hp) at 13,000 rpm while maximum torque exceeds 120 Nm (12.2 kgm) from 8,750 to 12,250 rpm.

The Desmosedici Stradale is designed around the Desmodromic system that controls the four valves in each cylinder and plays a key role in making Ducati prototypes the fastest in MotoGP. On this highrevving engine the “Desmo” system achieves a degree of sophistication, lightness and compactness never before seen on a Ducati.

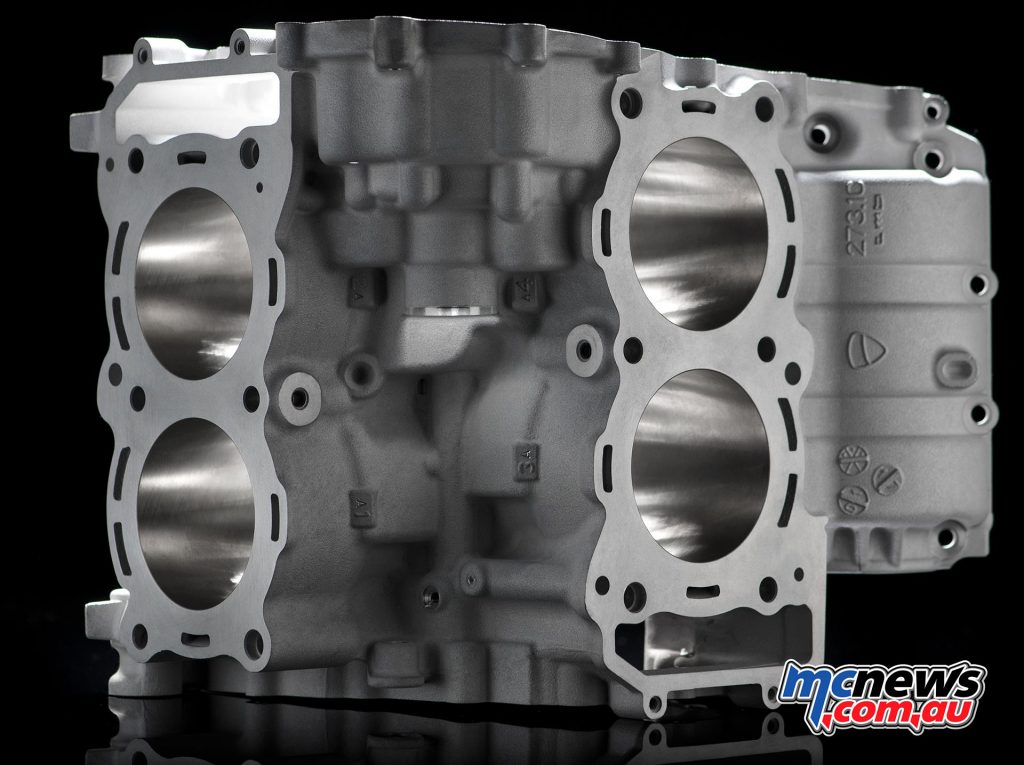

As in MotoGP, the engine was designed with an 81 mm cylinder bore. This measurement reflects the maximum limit allowed by MotoGP rules; it’s also the highest in the 4-cylinder supersport segment.

Using the same bore as the Desmosedici GP engine means both power units share nearly identical in engine fluid dynamics (i.e. on valves, intake ducts and throttle bodies, right where the power is produced).

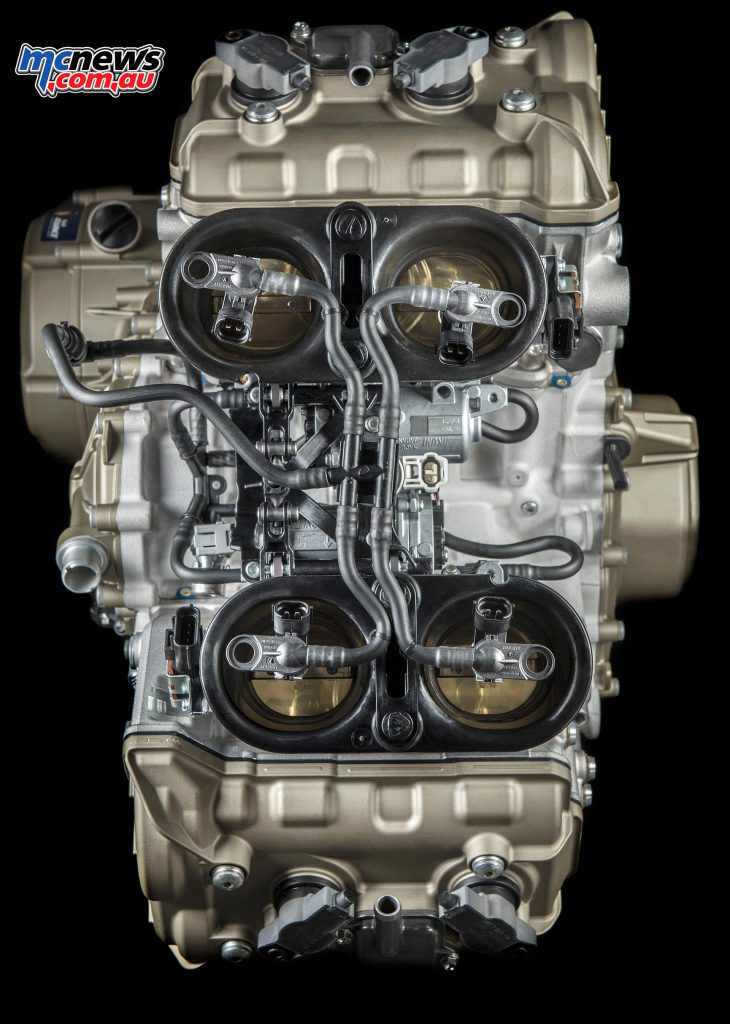

Throttle bodies have variable-height air intake horns that optimise cylinder intake across the rev range giving significant advantages in terms of power delivery and handling. Completing the fuelling system are the oval throttle bodies, each equipped with two injectors: one above the butterfly and one below it.

This technical solutions package – born in MotoGP and developed to maximise everyday reliability – once again demonstrates the uniqueness of Ducati, capable of creating a V4 engine that offers a

configuration and a solutions set like no other in the motorcycle world.

90-degree V4: the racing engine par excellence

Ducati sees the 90-degree V4 layout as the pinnacle of motorcycle engine sports performance. It’s no coincidence that this same solution is employed on Desmosedici MotoGP engines. The 90-degree V layout evens up first order forces naturally without having to resort to a balancing countershaft to eliminate vibration, a solution that, as is known, increases weight and drains power. This key benefit, crucial to the reliability and mechanical efficiency of an engine that revs as high as 14,000 rpm, is just one of many that make this Ducati-selected configuration the most technically refined possible.

Compared to a classic in-line 4, the lateral compactness of the V arrangement allows for better mass centralisation and reduces the bike’s frontal cross-section. Moreover, the shorter crankshaft diminishes the gyroscopic effect. All these aspects have a positive impact on motorcycle dynamics, making it lighter and faster when changing direction. Ample space inside the V provides room for both the water pump and an outsize airbox (12.8 litres) that lets the Desmosedici Stradale breathe better.

Smooth integration of engine and chassis set-up forms the foundation of every Ducati. That’s why the Desmosedici Stradale is designed to be banked rearward 42°, just like the Ducati engines used in MotoGP. This optimises weight distribution, allows for larger radiators and brings the swingarm pivot as far forward as possible.

Moreover, the Desmosedici Stradale has been designed as a structural chassis element. The main frame attachment points have been incorporated in the front of the upper crankcase half and in the rear cylinder bank head. What’s more, the crankcase acts as a rear suspension and swingarm attachment point.

Light and compact

Synergies with Ducati Corse has yielded a compact, light, high-performance engine. Meticulous design and development by Ducati’s engine team has resulted in power delivery that maximises road riding pleasure and gives supreme track performance.

Weighing in at 64.9 kg, the Desmosedici Stradale is just 2.2 kg heavier than the 1,285 cc Superquadro twin, clearly demonstrating the attention to lightness that lies at the heart of every Ducati project.

Engine casings are made of gravity die cast aluminium and are coupled horizontally. The upper crankcase half incorporates the four Nikasil-coated aluminium cylinder liners ensuring wear protection and low friction.

The 81 mm diameter pistons that slide inside the liners have two low-attrition compression rings and an oil ring. Made of moulded aluminium, the pistons feature “box in box” technology: this contains both skirt height and below-chamber thickness, helping to reduce attrition and inertial loads while maintaining the necessary strength and stiffness.

Racing-derived design is also underscored by a high compression ratio of 14:1. The pistons are coupled to forged steel con rods with a centre-to-centre of 101.8 mm.

Mounted on brass bushings, the crankshaft rotates on three supports and is made of nitrided steel with crank pins ground twice over and offset at 70° as on the Desmosedici engines that compete in MotoGP.

This particular shaft geometry, combined with the V engine layout, allows for a special “Twin Pulse” ignition sequence.

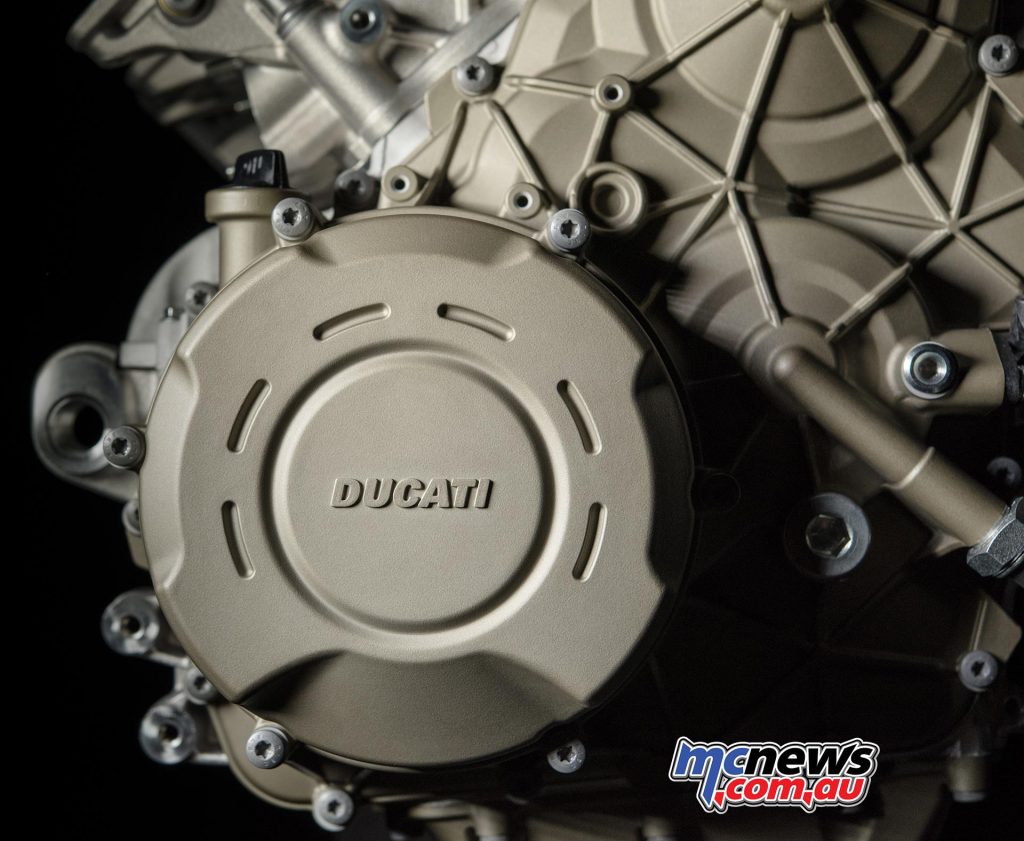

To limit weight, all engine casings are made of die cast magnesium. The same material has been used to make the cam covers, the oil sump, the alternator cover and the two-piece clutch cover.

Counter-rotating crankshaft

On normal factory bikes, the crankshaft turns in the same direction as the wheels. In MotoGP, instead, counter-rotating crankshafts that run in the opposite direction are widely used. Ducati engineers have borrowed this top-level racing solution for the same reasons that first saw it applied in competition. Its benefits stem from two aspects of physics: gyroscopic effect and inertia. A counter-rotating crankshaft offsets some of the gyroscopic effect generated by the turning wheels and that, in turn, improves handling and makes the bike more agile when changing direction.

The second benefit has to do with the inertia (i.e. the tendency of an object to oppose any change of state) of the vehicle and the rotating engine parts. During acceleration, drive torque is put down on the ground, causing the bike to wheelie. A counter-rotating crankshaft, however, produces inertia-linked torque in the opposite direction, lowering the front of the bike, limiting the wheelie effect and thus boosting acceleration performance.

Similarly, during hard braking/deceleration the bike undergoes rear wheel lift-up: however, the crankshaft itself also decelerates (i.e. its revs drop), producing an inertial torque that works against liftup. So a counter-rotating crankshaft has advantages during both acceleration and braking. Of course, this layout demands the addition of the so-called ‘jackshaft’ (*) to transfer crankshaft drive through the gearbox to the rear wheel so it turns the right way.

* The jackshaft adds an extra transmission element to the crankshaft-wheel connection system. This needs to be taken into consideration when establishing crankshaft power if the latter is obtained from measurements made at the wheel. During both homologation and measurement on acceleration test benches it is, therefore, necessary to consider an efficiency or, in any case, an additional coefficient that is, by law, fixed at 0.98.

Twin Pulse ignition

A combination of 70° crank pin offset and 90-degree V layout generates what Ducati calls a “Twin Pulse” firing order because it’s as if the engine were reproducing the firing sequence of a twin-cylinder. The distinctiveness lies in the fact that the two left-hand cylinders fire closely together, as do the two righthand ones. In the timing chart, the ignition points are, then, at 0°, 90°, 290° and 380°. It’s this particular firing order makes the V4 sound like a MotoGP Desmosedici.

In practice, if we imagine a cycle starting from 0°, the first cylinder to fire is the front one on the alternator side. After just 90° of rotation, the rear cylinder on the same side fires. There then follows an interval in which the engine generates no drive torque until the two cylinders on the clutch side fire, again just 90° apart. In addition to an exhaust rumble like no other in the motorcycle world, the Twin Pulse ignition sequence provides a power delivery that Ducati MotoGP riders deem unbeatable as it provides outstanding engine performance and, therefore, smooth handling, especially on corners and out-of-thecorner stretches.

Variable Intake System

The Desmosedici Stradale engine takes in air through four oval throttle bodies (52 mm diameter equivalent), connected to variable-height air intake horns, featured for the first time on a Ducati engine. This solution optimises cylinder intake across the rev range, giving major advantages in terms of power delivery and handling.

As rpm and rider-requested power vary, the air intake horns take on a configuration that lengthens or shortens the ducts, optimising the fluid dynamics of the pressure waves that run along the duct itself. Controlled by the ECU, the system consists of two stages: a fixed horn on the throttle body and a mobile one that is moved along steel guides by an electric motor. When the latter is lowered, it comes into contact with the short horn, geometrically lengthening the duct. When raised, the fluid dynamics involve only the fixed lower horn and the engine configuration is characterised by a very short duct.

Each throttle body has two injectors: a sub-butterfly one for low-load use and another above it that comes into play when maximum engine performance is required. The throttle bodies of each cylinder bank are moved by a dedicated electric motor. Thanks to the full Ride by Wire system, this allows complex electronic control strategies and modulation of engine ‘feel’ according to the selected riding mode.

Latest-generation Desmodromic system

As on all Ducati engines, the Desmosedici Stradale sees Desmodromic design playing a pivotal performance role. On the Desmosedici Stradale, the Desmodromic system uses fully redesigned, miniaturised components that have allowed for the construction of very small cylinder heads, achieving a degree of sophistication, lightness and compactness never before seen on a Ducati. Every single system component has been designed and tested to operate safely at the high revs the V4 is capable of. New spark plugs – smaller than standard models – also help keep the heads compact. The four Desmosedici Stradale engine camshafts control the sixteen valves: valve diameters are 34 mm diameter on intakes and 27.5 mm on exhausts, values decidedly on the high side given the 81 mm bore.

The valve seats are made of sintered steel. Given the high revs attained by the V4 and the large valves, a traditional spring system would be inadequate because the valves would be unable to follow the steep cam profiles. This, then, is where the Desmodromic system becomes a must. With the “Desmo” system the valves are closed mechanically with the same level of accuracy as they’re opened. This allows the steep cam profiles and radical cam timings that optimise intake and exhaust fluid dynamics to provide higher engine performance.

The camshafts are controlled by two “silent” timing chains. At the front, the chain drives the intake camshaft which, in turn, transmits drive to the exhaust camshaft via a pair of cogs (hybrid chain-cog timing). On rear timing, instead, the chain drives the exhaust camshaft, which transmits drive to the intake camshaft. This solution minimises timing power absorption, enhancing performance and reliability.

Front cylinder timing is controlled by the chain on the right-hand side of the engine, turned by the crankshaft via a gear obtained on the primary drive pinion. The one that controls rear cylinder timing is on the left-hand side of the engine and is driven by a monobloc gear on the crankshaft. Each cylinder head has an “anti-knocking” sensor that optimises spark advance to prevent any combustion shock.

Semi-dry sump lubrication

As on MotoGP engines, the Desmosedici Stradale uses semi-dry sump lubrication with delivery and return stages that ensure effective lubrication of all moving parts at all times. The oil circulation system consists of four pumps: one delivery lobe pump and three recovery pumps. One of the latter, a gear pump, draws oil from the heads via two ducts while the other two lobe pumps ensure efficient oil recovery under all conditions, keeping the crankcase zone under the pistons in a controlled, constant low pressure state and thus reducing airing losses (i.e. power absorption caused by the aerodynamic resistance exerted by the air and splashing of the oil in the con rod casing).

The oil tank – which also acts as a filter housing – is in a magnesium sump mounted underneath the crankcase and connected to the gearbox but separate from the crankcase. A dedicated radiator, attached just below the water radiator, cools the oil.

Cooling system

Housed in the engine ‘V’, the water pump is operated by a shaft, in turn driven by a gear train. This positioning solution is designed to minimise circuit size, boost efficiency and optimise engine weight.

Gearbox and clutch

The 6-speed gearbox is specially designed for the Desmosedici Stradale engine and features a rotary gear sensor to ensure optimal operation with Ducati Quick Shift (DQS) up & down. The sensor assesses the position of the gear shift drum and, consequently, of the gear shift forks, with extreme accuracy to ensure precise gear selection. This, then, allows for a strategy that can restore torque transmission only once the gear change has been completed, thus preventing undue gear mesh stress so shifts are always complete, precise and swift.

The hydraulically controlled wet clutch has 11 driving plates and features a progressive self-servo mechanism that compresses the friction plates when under drive from the engine without requiring any extra effort from the rider to release the clutch.

While enhancing frictional efficiency, this also results in a rider-friendly, light clutch lever “feel”. In sport riding conditions, the same mechanism reduces pressure on the friction plates, enabling a pure racing “slipper” action and reducing rear end destabilisation during aggressive down-shifting, with the added benefit of a super-responsive lever.

Long maintenance intervals

While performance levels surpass even those of the Superquadro, the valve clearance inspection and adjustment (Desmo Service) interval remains at 24,000 km (15,000 miles), while general service intervals remain unchanged at 12 months/12,000 km (7,500 miles).