Racing Electric Motorcycles

The modern history and examining the future

Competition brings innovation and excitement like little else, and as motorcycling is a joy largely driven by passion, this will mean so much to the EV market as it evolves in relation to electric motorcycles.

The MotoE category enjoys a spot on the dance card at some MotoGP events but had an inauspicious start as the opening two rounds themselves had to be abandoned after a major fire destroyed much of the charging infrastructure and machines themselves.

The inaugural 2019 season eventually did see four rounds held with six races. That increased to five rounds in 2020, and then six rounds in 2021. The early races were run over race lengths of around 35 km, roughly a third of the distance of what a MotoGP race covers.

Four of the five rounds scheduled for 2022 have already been run with the most recent races staged alongside the Dutch TT at Assen. At that event the MotoGP bikes covered 26 laps (118.092 km) with a fastest lap of 1m32.500 by Aleix Espargaro on the Aprilia RS-GP. In contrast, the opening MotoE race of the weekend covered only an eight-lap, 36.336 kilometre distance with a fastest lap of 1m43.086. This compares to the 22 lap (99.924 km) distance covered by the lightweight 250 cc single-cylinder motorcycles of the Moto3 category, where the fastest lap was 1m41.190. Weight is the primary issue holding the electric motorcycles back in lap-times, while range is what prevents them from being able to contest traditional race distances.

Heavy weight means their lap-times are often slower than even the 250 cc single-cylinder Moto3 bikes.

This season, 2022, will be the final one for the inaugural machine supplier to the MotoE category, Energica, but 2023 heralds a new era for the class with Ducati stepping up put their profile on the line in what could essentially still be called a fledgling new category.

It does seem somewhat ironic though that the first high profile motorcycle racing event to breathe the first breaths of life into electric motorcycle competition is the worlds oldest motorcycle racing event, the Isle of Man TT. The TT first introduced a category for electric motorcycle with the TTXGP event in conjunction with Azhar Hussain in 2009, before that then became TT Zero in 2010.

The long 61 kilometre Mountain Course was a massive challenge for these early battery powered machines and the distance they had to cover presented momentous challenges in battery management. The TT Zero race in 2010 was won by American Mark Miller at an average speed of 96.820 mph in 23-minutes-23secs.

Progress came rapidly though, with Rutter’s race winning lap in 2013 nudging 110 mph, before Rutter broke the 120 mph barrier in 2018 and improved again in 2019 to a lap average of 121.91 mph on the Mugen, almost five-minutes quicker than Miller’s inaugural race lap in 2010.

Rutter’s 2019 lap was only 12 mph behind the fastest lap of the Senior TT that year, but again, the TT Zero bikes could only manage one lap at race speeds. A conventional Superbike in the Senior TT covers an incredible 366 kilometres during the race, albeit with two fuel stops, but of course those fuel stops take seconds, that’s in stark contrast to the time required to charge the batteries in an electric motorcycle.

The Isle of Man TT was the first high profile event to adopt a racing category for electric motorcycles

Despite the rapid progress of the TT Zero machines a lack of entrant numbers, and the lack of a relation to motorcycles seen on public roads, saw TT organisers put a moratorium on the category until at least 2024.

So basically as TT Zero came to a halt, MotoE just got started… And now, with Ducati, it is readying to make the next step along the evolutionary ladder for 2023.

Due to being owned by Audi, which in itself is owned by the larger Volkswagen Group, one would imagine that Ducati would already be one of the motorcycle manufacturers most likely to hit the ground running when electric motorcycles become a practical reality.

But I think their partnership with Dorna to provide the motorcycles used in the MotoE category from 2023 will provide the greatest impetus by which Ducati may propel themselves to the forefront of the two-wheel EV market.

Despite their involvement in the MotoE category, it is clear that Ducati see this foray as an important step to train their next generation of engineers and innovators and set the company up for the future.

Like most of us that live in the real world, Ducati also realise that currently the battery technology and charging network availability does not make it viable for them to put an electric motorcycle into production. They say so themselves in this video released overnight that gives a great insight into their MotoE project.

Claudio Domenicali – Ducati CEO

“A few weeks ago I had the extraordinary opportunity to ride the Ducati MotoE on the track and I immediately realised that I was living in a historic moment. The world is going through a complex period and environmental sustainability is an element that all individuals and all companies must consider a priority if we want to preserve the delicate balance of the planet. As Ducati, we have grasped this need and we went in search of a challenge that would allow us to contribute to the common goal of reducing CO₂ emissions and at the same time to keep faith with our DNA linked to racing. We agreed with determination to develop the most performing electric racing bike that current technology makes possible and to use this project as a laboratory in which to build our future. The result we have achieved is surprising. As soon as I sat on the bike I realised the quality of the work done by the team and when I returned to the garage I felt a deep sense of pride for what we were once again able to achieve.”

Included below are some fascination insights provided to us by Ducati about the “V21L” prototype and the process used to get to where they are with the project right now.

Ducati outline their MotoE V21L project

The division of tasks and the continuous dialogue between the people who make up the team were fundamental throughout the process. Ducati R&D took care of all the Project Management activities, together with the design and simulations on the electric powertrain, while the design of the MotoE was taken care by the Centro Stile Ducati which also created the livery of the bike. Ducati Corse, on the other hand, worked on the electronic parts design, on the software controls and strategies, on the simulations of the dynamics and aerodynamics of the motorcycle and finally on the bike assembly, testing and data acquisition processes.

The result to date is already satisfactory: the Ducati MotoE has a total weight of 225 kg (12 kg less than the minimum requirements imposed by Dorna and FIM for a bike capable of completing the race distance) and can count on maximum power and torque figures of 110 kW (150 hp) and 140 Nm respectively, which allowed it to reach a speed of 275 km/h on a circuit like Mugello (Italy).

Vincenzo De Silvio – Ducati R&D Director

“For Ducati, having the opportunity to become suppliers of the FIM MotoE World Cup is not only a technologically exciting venture, but also the best way to interpret the challenges of the new millennium. Racing competition represents the ideal terrain on which to develop innovative technologies that will then transfer to production motorcycles. At this moment, the most important challenges in this field remain those related to the size, weight, autonomy of the batteries and the availability of the charging networks. Ducati’s experience in the FIM MotoE World Cup will be a fundamental support for product R&D, together with the physiological evolution of technology and chemistry. Helping the company’s internal expertise to grow is already essential today to be ready when the time comes to put the first street electric Ducati into production.”

The mix of expertise, passion and work of the Ducati MotoE team has led to the birth of an electric motorcycle with unique technical solutions. Starting with the battery pack, the most binding and characterising element in terms of masses and dimensions, which on the Ducati MotoE is characterised by a shape specifically designed to follow the natural course of the middle area of the bike. The battery pack weighs 110 kg and offers a capacity of 18 kWh with a 20-kW charging socket integrated into the tail. Inside there are 1,152 cylindrical cells of the “21700” type.

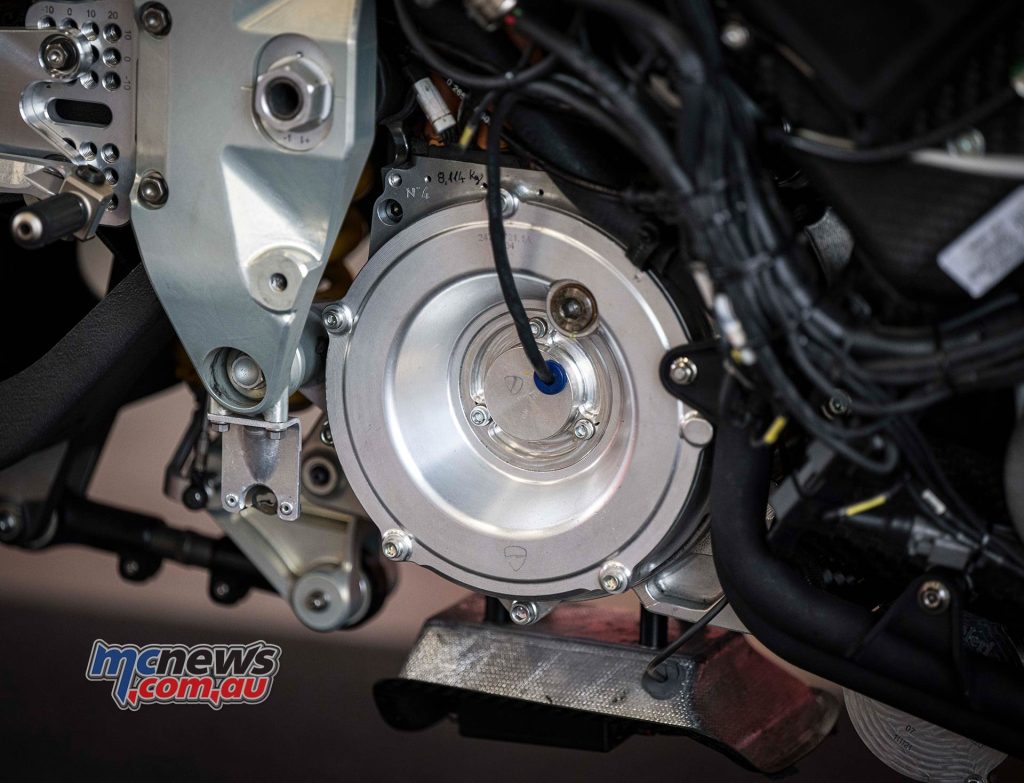

The inverter, with a low weight of 5 kg, is a unit derived from a high-performance model used in motor racing for electric vehicles, while the motor (21 kg weight and a maximum rotation speed of 18,000 rpm) was developed by a partner following the technical specifications provided by Ducati. The entire system is based on a voltage of 800V (with a fully charged battery pack) to maximise the output of the electric powertrain and, as a consequence, performance and range.

One of the most advanced technical solutions tested on the Ducati MotoE concerns the cooling system. The prototype components are in fact cooled by a particularly sophisticated and efficient liquid system with a double circuit designed to meet the different thermal needs of the battery pack and the motor/inverter unit. This guarantees extreme regularity of temperatures with important benefits in terms of consistency of performance but also in charging times. In fact, it is not necessary to wait for the battery pack to cool to start the process: the Ducati MotoE can be charged as soon as it enters the garage, and it takes about 45 minutes to recharge it up to 80 per cent of its range.

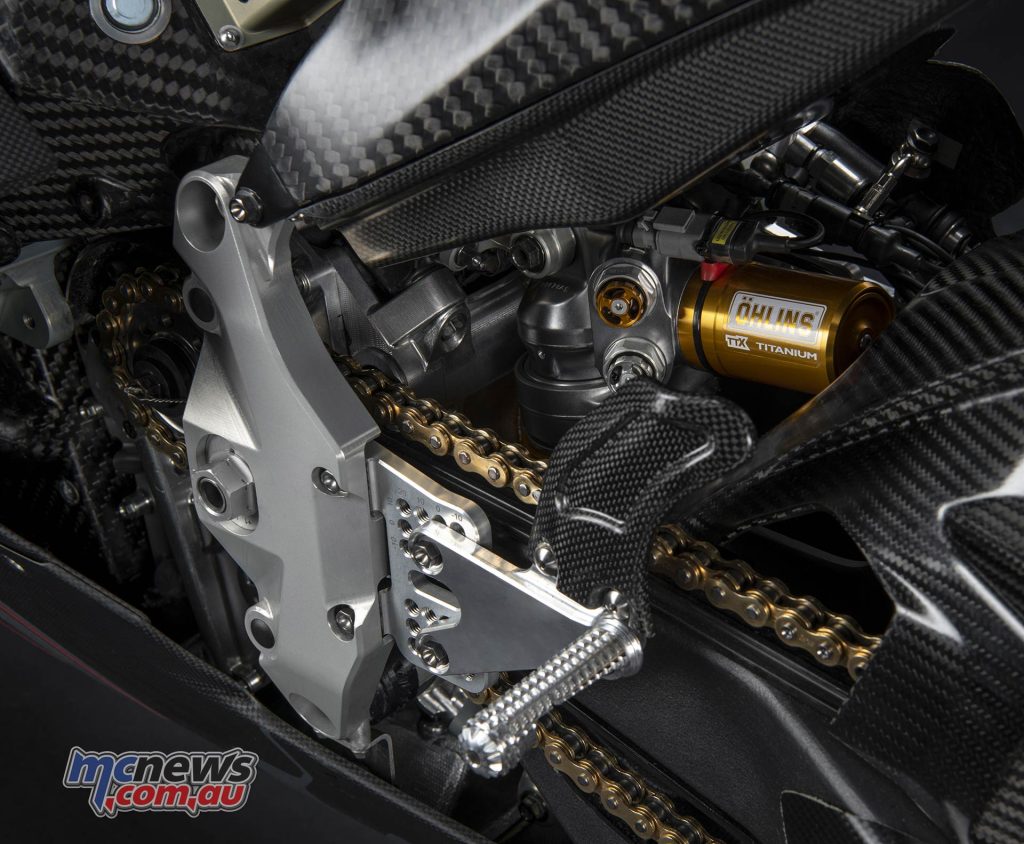

The carbon fibre case of the battery pack also acts as a stressed part of the chassis, like what happens for the Ducati Panigale V4 engine, with an aluminium monocoque Front Frame for the front area weighing 3.7 kg. The rear is composed of an aluminium swingarm weighing 4.8 kg with a geometry like that of the Ducati Desmosedici racing in MotoGP. The rear subframe, which integrates the tail and the rider seat, is made of carbon fibre.

The suspension area features an Öhlins NPX 25/30 pressurized fork with 43 mm diameter upside-down tubes at the front, derived from the Superleggera V4, while an Öhlins TTX36 shock absorber is present at the rear and is fully adjustable. The steering damper is an adjustable Öhlins unit.

The braking system is supplied by Brembo and is sized for the specific requirements of the Ducati MotoE. At the front it is composed of a double steel disc with a diameter of 338.5 mm of increased thickness, which has fins on the internal diameter with the aim of increasing the thermal exchange surface area and improve disc cooling in conditions of extreme use on the track. Two GP4RR M4 32/36 calipers with a PR19/18 radial master cylinder operate on this double disc. At the rear, the P34 caliper acts on a single disc unit 220 mm in diameter and 5 mm thick with a PS13 master cylinder. Teams can also choose to equip their bikes with an optional rear brake control positioned on the left handlebar, which the rider can use as an alternative to the pedal one.

Roberto Canè – Ducati eMobility Director

“I remember the birth of the MotoE project and every phase of the composition of the work team well, with the involvement of Ducati Corse colleagues and the search for contacts within the Volkswagen Group who could give us suggestions on how to develop this project. To make this bike we followed the same procedure that we usually follow on a production bike. We started by defining the design of the bike and in parallel the technical office began to design the various vehicle components. The initial brief was to create a racing bike that respected the minimum performance characteristics required by Dorna. As a matter of fact, this project has made and is making the whole team involved fall in love and is pushing us to create a bike with better characteristics than initially requested by the organiser.”

The development process of the Ducati MotoE also involved the Ducati Corse test team led by Marco Palmerini, who worked on the track applying the same methodologies used in MotoGP, thanks also to the support of the riders Michele Pirro, Alex De Angelis and Chaz Davies. Through the work on the electronics, the aim was to obtain a throttle response like that of an endothermic unit and a response from the electronic controls (such as Ducati Traction Control, Ducati Slide Control, Ducati Wheelie Control and throttle/engine brake maps) indistinguishable from that of the racing bikes that Ducati riders are used to.

The possibility of applying the development and test method already used in MotoGP, with a precise sequence of tests to be carried out on the various components to maximize the performance of each day on the track, was achieved also thanks to the efficiency of the cooling system, which has reduced charging times to a minimum, thus allowing for a truly significant continuity of use for an electric motorcycle. The development work involved a specific learning and training course for all the personnel involved, exploiting the knowledge shared within the Volkswagen Group, to ensure the total safety of the rider and technicians.

The fact that Ducati belongs to the Volkswagen Group, which has made electric mobility an essential element of its “New Auto” 2030 strategy, represents the best prerequisite for an extraordinary exchange of expertise in the field of electric powertrains. Ducati is in close contact with the Group’s centres of expertise and with the Centre of Excellence (CoE) at Salzgitter in Germany, but also with other brands of the Group such as Porsche and Lamborghini.

The work plan of the Ducati MotoE project has already reached an advanced stage of development and is proceeding at a rapid pace towards 2023, the year in which Ducati will take on the role of sole supplier of the FIM MotoE World Cup with 18 electric motorcycles on the track every weekend. The next objective for the Bologna-based manufacturer is to take advantage of participation in the most important racing competition in the world for electric motorcycles to experiment with innovative technologies, train new skills and study how to create, as soon as the technology will allow, a Ducati electric vehicle that is sporty, light, exciting and able to satisfy all enthusiasts.