Ducati brings fully variable valve timing to the masses – By Trevor Hedge

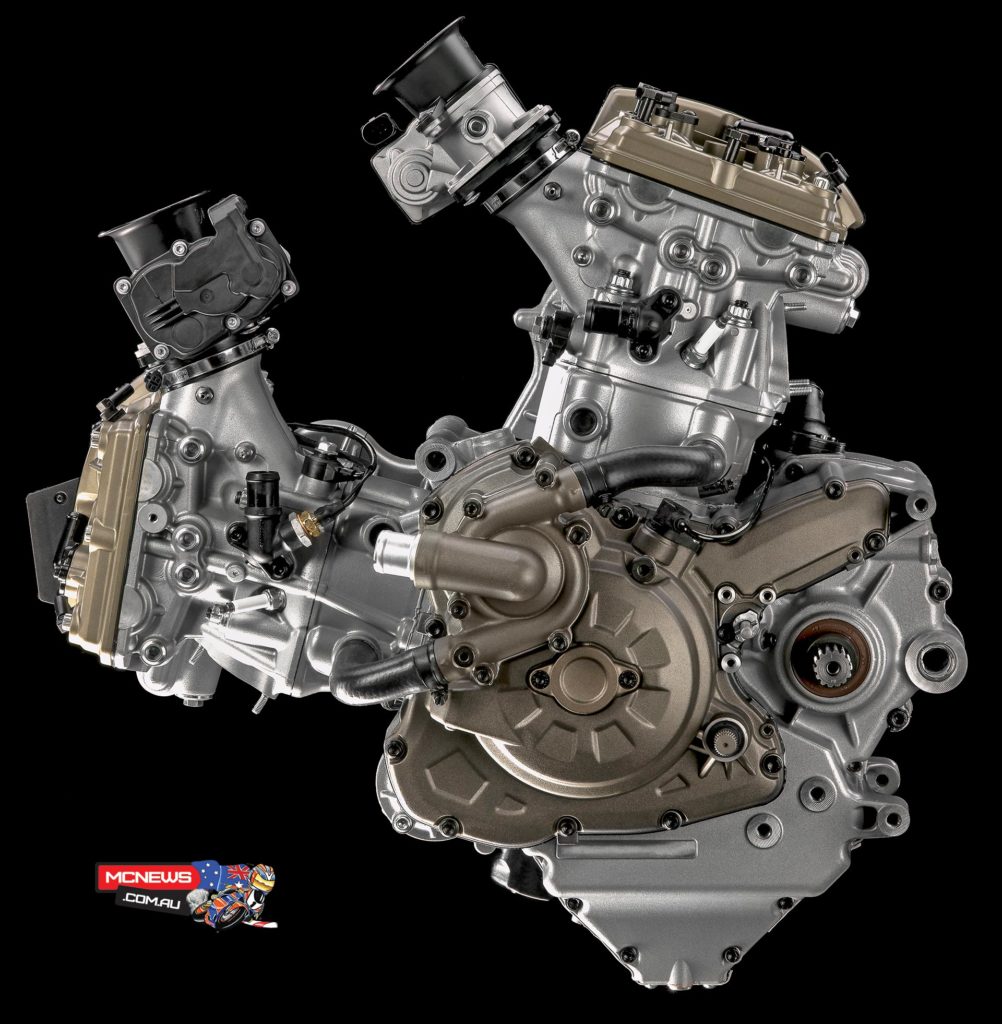

Overnight Ducati has released their plans to bring fully variable valve timing on both the exhaust and intake camshafts to mainstream motorcycle production. While other manufacturers have offered variable timing on one of the cams, generally inlet, or a stepped change in valve area by introducing more valves as revs rise, no mainstream motorcycle as yet has brought fully variable valve timing to production. Ducati are set to change that with a new 1198cc, 160hp v-twin.

Full variable valve timing across both cams is extremely common in car engines but motorcycle manufacturers have held off implementing it on road going motorcycles, perhaps due to the incredible advances in cylinder head design and engine management systems that already make modern motorcycle engines so flexible and efficient, but Ducati have been the first ones out of the blocks to up the stakes in this area.

Named Ducati Testastretta DVT, not for Deep Vein Thrombosis but for Desmodromic Variable Timing, Ducati’s new Desmodromic engine is the first in motorcycling with variable timing on both inlet and exhaust camshafts, leading the way for a whole new generation of such engines from the Bologna manufacturer.

Effectively, variable valve timing allows for what would have been wild cam profiles in the upper end of the rev range, that conventionally in turn would have made the motorcycle a complete pig down low, but variable valve timing can give you the best of both worlds and also allow for short duration valve openings at low rpm, ensuring smooth running lower in the rev range and also much more torque and fuel efficiency than otherwise could be gained from having cams that would also have allowed storming top end performance. The less cylinders you have generally means the less valve area you have to play with, thus why Ducati’s higher performance twins use such huge bores, to allow for expansive cylinder heads and lots of valve area, thus single and twin cylinder engines have perhaps the most to gain from variable valve timing.

Below is a summary of features and blurb provided by Ducati on their new innovation. I must say, we are quite excited by this and look forward to seeing how this new 1198cc twin behaves on the street, as it is on the street and in the real world where these innovations will be most beneficial.

Ducati Testastretta DVT engine characteristics

- · Brand-new DVT (Desmodromic Variable Timing) system

- · Bore 106 mm, stroke 67.9 mm

- · Capacity 1,198 cm³

- · Max power 160 HP at 9,500 rpm

- · Max torque 136 Nm at 7,500 rpm

- · Desmodromic distribution

- · Dual Spark (DS) ignition

- · Anti-knock sensor

- · Euro 4 compliant

By independently adjusting both the timing of the camshaft controlling intake valves and the timing of the camshaft controlling exhaust valves, the Ducati Testastretta DVT engine optimises high rpm performance for maximum power, while at medium and low rpm, it ensures smooth operation, fluid power delivery and high torque. This means that the vehicle’s engine will adapt its characteristics according to rpm values, while always ensuring compliance with exhaust emission standards and keeping fuel consumption low.

When a new engine is designed, one of the most critical parameters to determine its ‘character’ is the amount of intake and exhaust valve overlap. The overlap angle is defined as the interval of crankshaft rotation, expressed in degrees, during which both the intake and exhaust valves are open at the same time. This overlap occurs between the end of the exhaust stroke and the start of the intake stroke and is normally a single value that does not change. However, the Testastretta DVT is not limited by a fixed valve overlap angle.

Instead, the Ducati Testastretta DVT’s overlap angles can change, thanks to the introduction of the DVT (Desmodromic Variable Timing) system: a valve timing adjuster fitted to the end of each of the two camshafts per cylinder head. The DVT system consists of an external housing, rigidly connected to the cam belt pulley, and an internal mechanism which is connected to the camshaft and can independently rotate inside the housing. This rotation of the internal mechanism, either in advance or in delay with respect to the housing, is precisely controlled by varying the oil pressure in special chambers of the mechanism. The oil pressure is adjusted by dedicated valves and the timing of each cam is dynamically controlled by a sensor located in the cam covers.

The Ducati Testastretta DVT engine uses the unique valvetrain that made the Bologna-based Italian manufacturer a world-famous name. Thanks to this unique system, the intake and exhaust valves are closed mechanically and with the same level of accuracy as they are opened. The term Desmodromic derives from the Greek words “desmos=link” and “dromos=stroke, travel”; in mechanical engineering terms, it refers to mechanisms designed to actuate valves both in the opening direction and in the closing direction.

This system, used in all Ducati models, has also been extremely successful in Ducati Corse World Superbike and Desmosedici MotoGP motorcycles. In the development of the DVT, the Desmodromic valvetrain represents a major advantage over a traditional spring based timing system; the actuation of the valves at low engine speed requires less force, not having to compress the valve springs, this allowed Ducati to limit the size of each cam phaser with obvious benefits in terms of lightweight construction and compactness for a perfect engine integration.

With its 106 mm bore and 67.9 mm stroke for a total capacity of 1,198 cm³, the newborn Ducati

Testastretta DVT engine produces a maximum power of 160 HP at 9,500 rpm, and a torque up to 136 Nm at 7,500 rpm with a perfectly linear delivery curve. The torque is already 80 Nm at a low-range value of 3,500 rpm, and it remains consistently over 100 Nm between 5,750 and 9,500 rpm.

Despite an increase in power, however, the DVT system has a positive impact on fuel efficiency, with an average 8% reduction in fuel consumption compared to the previous non-variable configuration.

Ducati’s permanent research and development efforts applied to injection systems have repositioned the fuel injectors to target their spray directly onto the rear of the hot intake valve, instead of the colder surface of the intake port wall. The resulting enhanced fuel vapourisation improves combustion efficiency and ensures a smoother delivery.

The Testastretta DVT is equipped with a Dual Spark (DS) system that uses two spark plugs per cylinder head, providing a twin flame-front that ensures complete combustion across a very short period of time. Each spark plug is managed independently, to optimise efficiency throughout the rev range and in all conditions of use. An anti-knock sensor ensures safe engine operation even while using lower octane fuel or in situations potentially detrimental to combustion efficiency, e.g. at high altitude.

In order to achieve a smoother cycle-to-cycle engine operation, Ducati has used a secondary air system similar to that developed for extremely high-performance engines. This optimizes combustion without increasing emissions, by completing the oxidisation of unburned hydrocarbonsto reduce HC and CO levels.

Thanks to all these characteristics, the Ducati Testastretta DVT sets new standards for Ducati twin-cylinder power units and introduces new, revolutionary parameters to achieve the best possible balance among maximum power, smooth delivery, low-rpm torque, low fuel consumption and reduced emissions, thus standing out as the most technologically advanced Desmodromic twin-cylinder engine on the planet.

The Ducati Testastretta DVT system does not affect the valve clearance adjustment schedule, and in fact requires major services only at ownership-friendly 30,000 km intervals. This engine can be used in a wide variety of conditions and locations, while always delivering top performance and exceptional user-friendliness, safety and sheer excitement.